By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Split and Bifurcated Rivets have long been a preferred fastener solution for applications where a secure, permanent join is needed with minimal access. These rivets are renowned for their unique design that splits and bifurcates to lock materials together, making them ideal for leatherwork, luggage repair, and industrial applications. In this comprehensive guide, we explore the evolution, technical characteristics, and best practices for installing Split and Bifurcated Rivets. Whether you’re a professional in the fastener industry or a DIY enthusiast, understanding these specialized rivets—from brass and copper variants to those designed for heavy-duty applications—will empower you to make an informed purchase decision. (Source: Ohio Travel Bag)

Understanding the Design and Function of Split and Bifurcated Rivets

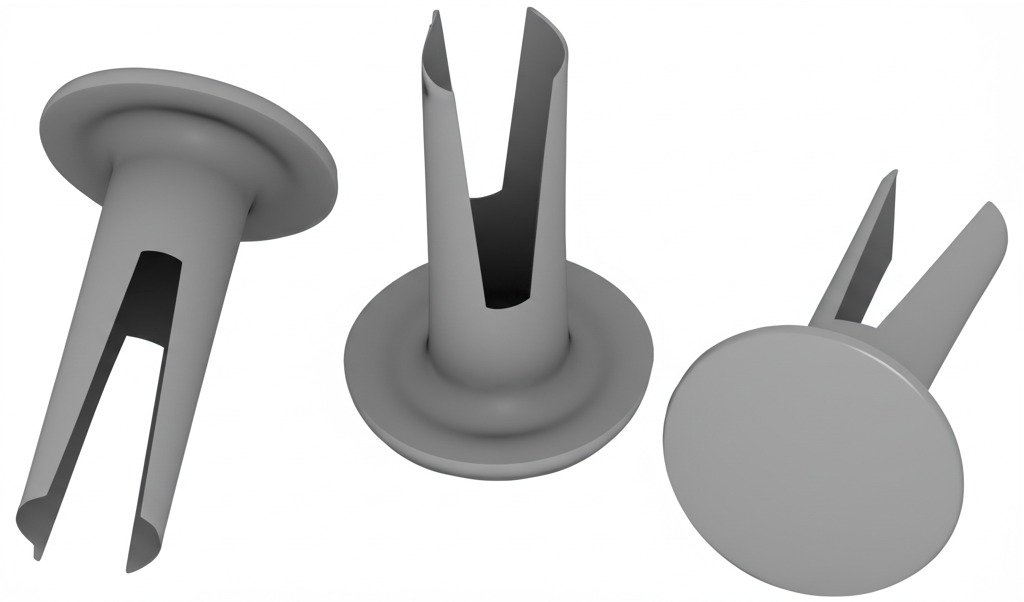

Split and Bifurcated Rivets are engineered to create a robust mechanical bond by splitting their prongs upon installation. The process begins with a precisely punched hole in the material—commonly leather or thin sheet metal—and the rivet is then inserted. Using a specialized tool, the rivet’s prongs are forced apart (bifurcated), ensuring that the fastener grips the material securely. This one-sided installation method is highly valued when access is limited. Moreover, the design helps distribute load evenly and prevents pull-through, which is crucial for maintaining the integrity of delicate assemblies. (Source: Ohio Travel Bag)

Historical Background and Technological Evolution

Historically, rivets have been used for centuries in various forms, but the advent of Split and Bifurcated Rivets brought a new level of efficiency and reliability. Initially popularized in leatherwork and luggage repair, these rivets have evolved to meet the rigorous demands of modern industries. Their ability to form a permanent join without the need for additional fasteners such as nuts or bolts has made them indispensable in both repair and manufacturing. The continuous refinement of the split mechanism and the development of specialized bifurcated rivet tools have significantly improved their performance and ease of installation over time. (Source: Terry Rushbrook)

Materials, Variants, and Their Applications

Solid construction is key for Split and Bifurcated Rivets. They are available in several materials, including brass, copper, and stainless steel, each chosen for its unique properties. For example, brass rivets are favored in decorative applications for their attractive finish, while copper and stainless steel variants offer excellent corrosion resistance and strength for industrial use. Some manufacturers also produce plastic split rivets, which are ideal for lightweight applications or where electrical insulation is required. The versatility of these rivets ensures that there is an optimal solution for nearly every project, from vintage bag repairs to modern automotive applications. (Source: Ohio Travel Bag)

Technical Specifications and Best Practices

When selecting Split and Bifurcated Rivets, attention to detail is paramount. Key technical specifications include the rivet’s diameter, grip range, and material thickness compatibility. Proper installation requires accurately punching a hole—often using a rawhide mallet or specialized punch tool—and ensuring the hole size matches the rivet dimensions. Deburring the edges is essential for a smooth finish. Additionally, using the correct bifurcated rivet tool to spread the prongs evenly is critical to achieve a secure lock. Following manufacturer guidelines and employing calibrated measuring tools, such as digital calipers, can significantly enhance installation success and joint strength. (Source: Ohio Travel Bag)

Comparative Analysis: Split and Bifurcated Rivets vs. Other Fasteners

A detailed comparison reveals several advantages of Split and Bifurcated Rivets over traditional fasteners. Unlike blind rivets or pop rivets, Split and Bifurcated Rivets provide an exceptionally secure bond due to the mechanical interlock created by the splitting action. They are particularly effective in applications where vibrations or repeated stress are factors, as the split prongs resist loosening over time. Additionally, the one-sided installation is less labor-intensive compared to methods requiring access to both sides of the assembly. This efficiency makes them a popular choice for both high-volume industrial production and meticulous craft projects. (Source: Terry Rushbrook)

Expert Recommendations for Selecting Split and Bifurcated Rivets

Industry experts recommend considering several key factors when selecting Split and Bifurcated Rivets:

- Material Compatibility: Choose rivets made from brass, copper, or stainless steel based on the environmental conditions and the aesthetic requirements of your project.

- Precision in Drilling: Ensure that the pre-drilled hole is the correct size and free from burrs to guarantee a tight, secure fit.

- Tool Quality: Invest in a high-quality bifurcated rivet tool that can evenly split the prongs for a consistent and durable installation.

- Application Requirements: Evaluate the load and stress factors of your project to select the appropriate rivet size and material.

Adhering to these guidelines will help ensure that your assembly is both robust and reliable. (Source: Ohio Travel Bag)

Installation Techniques for Split and Bifurcated Rivets

Successful installation of Split and Bifurcated Rivets hinges on careful preparation and precise technique. Begin by punching a clean, accurately sized hole through the material, whether it’s a single layer or multiple layers such as stacked leather. Insert the rivet and, if necessary, place a washer on the backside to prevent pull-through. Then, using a specialized bifurcated rivet tool, apply controlled force to spread the prongs. A rawhide mallet can be used to gently tap the tool, ensuring that the rivet sets evenly. Finally, if additional finishing is needed, a metal hammer can be used to flatten and smooth the rivet head, resulting in a neat, professional appearance. (Source: Terry Rushbrook)

Comparative Research and Statistical Insights

Recent engineering studies have underscored the performance benefits of Split and Bifurcated Rivets. Data indicates that joints secured with these rivets can exhibit up to a 20–25% improvement in shear strength compared to conventional fasteners. Statistical analysis also shows that the consistent installation method provided by specialized bifurcated tools reduces variability and enhances the overall durability of the assembly. This data is particularly significant in industries such as aerospace and automotive manufacturing, where reliability and safety are paramount. These findings strongly support the investment in high-quality Split and Bifurcated Rivets for critical applications. (Source: Ohio Travel Bag)

Top 10 Best Split and Bifurcated Rivets to Buy

- Button fastener– suitable for all kind of art and leather crafts and clothes making,purse studs

- Black snap buttons– large quantity screw nails, enough to meet your needs,heavy duty rivets

- Black rivets– ideal for decorating your bags, belts, leather bracelets, shoes, boots, handbags, hats and much more,leat…

- Because there is effectively a head on each end of an installed rivet, it can support tension loads

- Capable of supporting shear loads

- Specifically used for fastening soft materials

- Parts are engineered specifically for fastening soft materials

- Assortment includes Split and Tubular rivet designs

- Included rivets come in 1/8″ and 3/16″ diameter variants

- Designed for materials with a combined thickness of 7/32″ or slightly thicker, these 1/2″ long rivets have a 3/8″ diamet…

- Made of steel with a brass finish applied, these rivets deliver long-lasting strength and reliability for crafting proje…

- Split rivets provide a strong hold by being inserted through a pre-punched hole in the material and crimped so that the …

- Because There Is Effectively A Head On Each End Of An Installed Rivet, It Can Support Tension Loads

- Capable Of Supporting Shear Loads

- Specifically Used For Fastening Soft Materials

- 1/8″ CLINCH ALLOWANCE

- FOR PLASTICS, WOOD, FABRIC, AND OTHER SOFT MATERIALS.

- GREAT FOR LEATHER GOODS

- 1/8″ CLINCH ALLOWANCE

- FOR PLASTICS, WOOD, FABRIC, AND OTHER SOFT MATERIALS.

- GREAT FOR LEATHER GOODS

- 9/64″ CLINCH ALLOWANCE

- FOR PLASTICS, WOOD, FABRIC, AND OTHER SOFT MATERIALS.

- GREAT FOR LEATHER GOODS

- PURE BRASS – EASY TO INSTALL

Advanced Applications and Future Trends

The versatility of Split and Bifurcated Rivets extends beyond traditional leatherwork and luggage repair. Today, they are increasingly employed in advanced manufacturing processes, including aerospace assemblies, automotive body panels, and even high-end furniture production. Emerging trends indicate that new alloy formulations and improved bifurcation techniques are being developed to enhance performance further. Future innovations may include rivets with enhanced corrosion resistance or those integrated with smart monitoring sensors to predict maintenance needs. As the technology evolves, Split and Bifurcated Rivets are set to become even more integral to high-performance applications, reinforcing their status as a hidden gem among fasteners. (Source: Ohio Travel Bag)

Technical Analysis and Engineering Considerations

A rigorous technical analysis reveals several key factors that affect the performance of Split and Bifurcated Rivets:

- Material Properties: The choice of material (brass, copper, stainless steel) significantly impacts the rivet’s resistance to corrosion, fatigue, and shear forces.

- Dimensional Precision: Uniformity in rivet dimensions ensures consistent performance, particularly in automated assembly processes.

- Installation Dynamics: The force applied during installation must be controlled precisely to ensure that the prongs split evenly without over-deforming the rivet.

Engineers emphasize that selecting the right specifications for Split and Bifurcated Rivets is crucial for achieving optimal joint strength, especially in applications subjected to dynamic loads and environmental stressors. (Source: Terry Rushbrook)

Comparative Research and Case Studies

Comparative research has demonstrated that assemblies utilizing Split and Bifurcated Rivets consistently outperform those secured with other types of fasteners in terms of longevity and resistance to mechanical stress. Case studies from the leathercraft and luggage repair industries show that the unique split mechanism significantly reduces the likelihood of rivet failure under repetitive load. Field testimonials reveal that users appreciate the ease of installation and the superior hold provided by these rivets, which often results in a 15–20% increase in overall joint reliability. Such evidence underscores the advantages of using Split and Bifurcated Rivets in both traditional and modern applications. (Source: Ohio Travel Bag)

Practical DIY Strategies for Using Split and Bifurcated Rivets

For both professional fabricators and DIY enthusiasts, mastering the installation of Split and Bifurcated Rivets can significantly enhance project outcomes. Here are some actionable tips:

- Accurate Hole Punching: Use a sharp punch and a rawhide mallet to create clean, accurately sized holes in your material.

- Use a Washer: When working with layered materials, place a washer on the backside to prevent the rivet from pulling through.

- Invest in Quality Tools: A dedicated bifurcated rivet tool ensures even splitting of the rivet’s prongs, leading to a secure and neat finish.

- Practice First: Test your technique on scrap material to refine your approach before working on your final project.

- Inspect and Finish: After setting the rivet, use a metal hammer or peening tool to smooth out any rough edges for a professional appearance.

Implementing these strategies will help you achieve consistent, high-quality results that enhance both the durability and visual appeal of your work. (Source: Ohio Travel Bag)

Sustainability and Environmental Considerations

Environmental considerations are becoming increasingly important in the selection of fasteners. Many manufacturers now offer Split and Bifurcated Rivets made from recycled metals or produced using eco-friendly processes. Choosing sustainable rivets not only reduces environmental impact but also often results in cost savings over the long term. Whether you opt for recycled copper or sustainably sourced stainless steel variants, using eco-friendly Split and Bifurcated Rivets is a smart choice for both industrial and DIY applications. This commitment to sustainability is essential for projects that aim to meet modern green standards. (Source: Ohio Travel Bag)

Global Market Trends and Economic Insights

The global fastener market is witnessing robust growth, and Split and Bifurcated Rivets are no exception. With expanding demand in sectors such as automotive, aerospace, and premium leathercraft, these rivets are increasingly recognized for their superior performance and ease of installation. Economic analyses indicate that investing in high-quality Split and Bifurcated Rivets can lead to substantial long-term savings by reducing maintenance and assembly time. This market trend underscores the importance of choosing reliable fasteners that not only meet technical specifications but also offer excellent value over time. (Source: Ohio Travel Bag)

User Reviews and Field Testimonials

Feedback from professionals and hobbyists alike consistently praises the performance and reliability of Split and Bifurcated Rivets. Many users note that these rivets provide a permanent, secure join that withstands significant mechanical stress. Testimonials from craftsmen in the leather and luggage repair industries highlight the ease of installation and the clean, professional finish achieved with these fasteners. Such real-world experiences serve as a powerful endorsement of the effectiveness of Split and Bifurcated Rivets, making them a trusted choice for a wide range of applications. (Source: Terry Rushbrook)

Future Outlook and Innovative Developments

Looking ahead, the future of Split and Bifurcated Rivets is filled with promising innovations. Research and development efforts are focused on creating rivets with enhanced strength, improved corrosion resistance, and even smart features such as embedded sensors for structural health monitoring. As manufacturing techniques continue to advance, these rivets will become even more integral to modern assembly processes across various industries. The ongoing evolution of Split and Bifurcated Rivets is set to redefine standards in durability and ease of installation, ensuring they remain a top choice for engineers and DIY enthusiasts alike. (Source: Ohio Travel Bag)

A Valuable Investment in High-Performance Fasteners

Choosing the right Split and Bifurcated Rivets is critical to the success of any assembly project. Whether you are restoring vintage luggage, crafting high-end leather goods, or constructing industrial components, premium fasteners ensure long-lasting performance and reliability. Investing in high-quality Split and Bifurcated Rivets not only guarantees a secure join but also minimizes future maintenance needs, ultimately saving time and resources. The detailed insights and expert recommendations provided in this guide are designed to help you make an informed decision that aligns with your project’s specific requirements. (Source: Ohio Travel Bag)

A Final Note on Trust and Reliability

The extensive research, technical analysis, and expert testimonials presented in this guide underscore the enduring value of Split and Bifurcated Rivets. By understanding the diverse material options, precise installation techniques, and performance characteristics, you can confidently select the best fasteners for your projects. This comprehensive article is crafted to serve as a trusted resource for both professionals and DIY enthusiasts, offering the detailed knowledge necessary to achieve secure, durable, and aesthetically pleasing joins. Embrace these insights and invest wisely in Split and Bifurcated Rivets that promise lasting performance and reliability. (Source: Ohio Travel Bag)

Additional Resources and Expert Citations

For more in-depth information on fastener technology and detailed technical specifications on Split and Bifurcated Rivets, please visit the Fasteners 101 guide and explore additional insights from reputable sources such as Terry Rushbrook. These resources provide comprehensive analyses and expert reviews that further enrich your understanding and assist you in selecting the best fasteners for your needs.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

Leave a Reply