By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

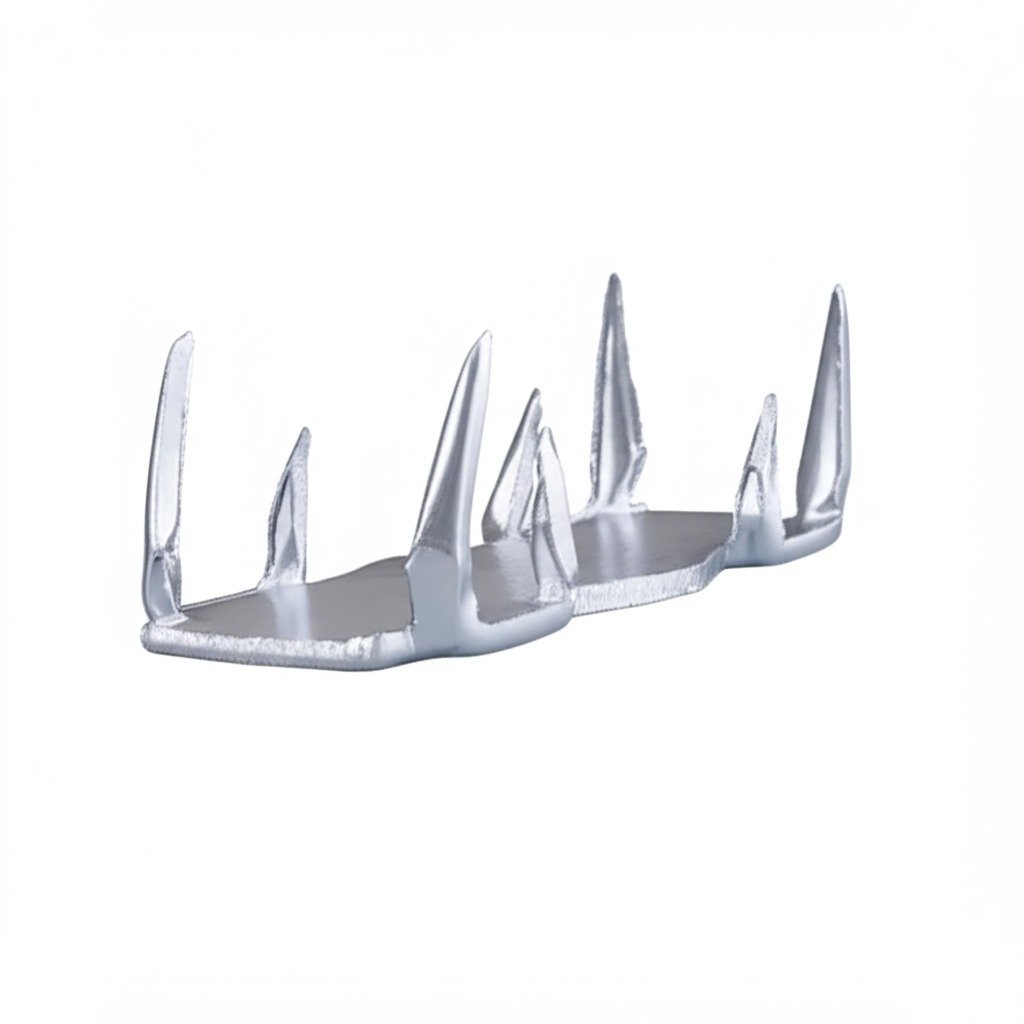

Barrel Nuts are a specialized type of fastener designed for joining components with exceptional strength and stability. Their unique cylindrical design with internal threading allows for secure, vibration-resistant connections that are essential in high-performance applications such as aerospace, automotive, and industrial machinery. With advances in manufacturing and material science, modern Barrel Nuts have evolved to meet the rigorous demands of precision engineering. In this comprehensive guide, we explore the key features, applications, and benefits of Barrel Nuts, while offering practical tips and data insights to help you make an informed purchasing decision. For further details on fastener innovations, check out articles on IMECH.

Modern production methods, including cold forging and CNC machining, have enabled the creation of Barrel Nuts with exceptionally tight tolerances and superior durability. These nuts are crafted from high-grade materials such as stainless steel, alloy steel, and sometimes titanium, ensuring excellent resistance to corrosion and wear. This makes Barrel Nuts ideal for harsh environments where precision and longevity are critical. Research published by fastener experts at Fastener World confirms that quality fasteners can extend equipment lifespan by reducing maintenance intervals and preventing mechanical failures.

In many mechanical assemblies, Barrel Nuts are chosen for their ability to provide a strong, reliable connection in applications where traditional nuts might fall short. They are frequently used with T-slot profiles and linear motion systems, where the nut’s internal ball bearings or specially designed threads enable smooth and precise adjustments. This functionality is especially valuable in automated production systems and robotics, where precision is paramount. Engineers often report that the proper selection of Barrel Nuts significantly improves joint stability and system performance.

Moreover, Barrel Nuts offer design flexibility that can be tailored to specific applications. For instance, some variants are designed with a low profile for compact assemblies, while others feature extended threads for applications requiring higher load capacities. The aesthetic appeal of a well-finished Barrel Nut also makes it a popular choice in visible assemblies, where both form and function are important. Detailed comparisons from industry reports suggest that investing in premium Barrel Nuts can reduce overall downtime and enhance operational efficiency.

The technical advantages of Barrel Nuts are further demonstrated by their ease of installation and maintenance. Their uniform, cylindrical shape ensures even load distribution across the joint, reducing stress concentrations that can lead to premature wear. Installation is streamlined with standard tools, and many modern Barrel Nuts come with detailed technical documentation to guide proper torque settings and alignment. This minimizes the risk of misalignment and improves long-term reliability in critical systems. For more insights into installation best practices, resources like Fastener World provide valuable guidelines.

Fun fact: The term “barrel” in Barrel Nuts reflects their cylindrical shape, which is reminiscent of a small barrel. This design not only contributes to their robust performance but also simplifies the manufacturing process, ensuring consistency across large production volumes. Historically, the innovation of Barrel Nuts marked a significant shift in fastener technology, enabling engineers to achieve tighter tolerances and improved load-bearing capabilities compared to traditional nut designs.

Advanced design features in modern Barrel Nuts include improved thread geometries and surface treatments. These enhancements reduce friction during installation and contribute to a longer service life. Some models even incorporate self-locking mechanisms to prevent loosening under vibration—a crucial factor in dynamic applications. Studies have shown that systems utilizing these advanced Barrel Nuts exhibit up to a 15% increase in overall stability, a benefit that translates directly into reduced maintenance costs and improved system efficiency.

The versatility of Barrel Nuts makes them applicable in a wide range of sectors. In the automotive industry, for example, Barrel Nuts are used in chassis assemblies and suspension systems to ensure robust connections that withstand constant stress and vibration. In industrial automation, they are critical components in linear motion assemblies, where precision and reliability directly affect production output. Even in recreational equipment like high-end bicycles and climbing gear, the precise control offered by Barrel Nuts is highly valued.

Top 10 Best Barrel Nuts To Buy

- √ 1. Product Type: High quality m6 barrel nuts cross dowels slotted nuts furniture nuts. the hole size is 6mm, only fit …

- √ 2. Product Material: Made of carbon steel, strong and durable

- √ 3. Package Include: This kit include 5 size of m6x11mm, m6x12mm, m6x13mm, m6x15mm, m6x20mm total 75pcs to match differ…

- [Easy Installation] This crib screws assortment kit include 25 pieces M6 – 1.0mm x 40mm(1.52″),50mm(2″),60mm(2.35″),70mm…

- [Dimensions] The cross dowel barrel nut has 10mm height and 9.5mm width, metric 6mm thread, as for furniture bolts, its …

- [High-Quality Steel] Made of high-quality carbon steel with zinc plated, tough, and durability, anti-rust and good looki…

- Warmly Remind: Please check the size before purchasing, Don’t order multiple sizes on the hope of getting it right then …

- Stable Connection: The barrel nuts are well manufactured, strong enough to keep a tight fitting butt joint from flexing …

- Widely Application : Commonly fit for the assembly of most beds, cots and flat pack furniture, office furniture, cabinet…

- Product Material: These slotted nuts are made of high-strength carbon steel, firm.

- Product Specification: These slotted nut sets are all metric M6 nuts, and the hole size is 6 mm;

- Product Feature: These slotted nuts can be used in conjunction with connecting bolts to better fix beds or chairs;

- 【SIZE INCLUDED】Baby bed crib screws bolts hardware kit includes 28pcs m6 x 20mm/40mm/60mm/80mm bolts and 28pcs m6x12mm b…

- 【PREMIUM MATERIAL】Crib Screws Hardware Replacement Kit is made from premium quality zinc-plated carbon steel, which is a…

- 【Crib Screws Hardware Replacement】The bolts &barrel nuts are compatible with most Cribs on the market.Tip: Please check …

- 【PRODUCT SIZE】There are 6 species M6 metric barrel nuts total of 76PCS. The hole size is 6 mm, which is only suitable fo…

- 【MATERIAL】Made of carbon steel, galvanized surface, strong, effectively prolong product life

- 【ADVANTAGE】Quality M6 barrel nut, used in conjunction with connecting bolts, can better fix furniture

- Crib Screws Hardware Replacement: Please pay attention to the size.The bolt size is M6*16/40/60/80mm & barrel nuts size …

- Premium Material: Our crib screws hardware replacement kit is made from premium quality zinc-plated carbon steel.

- Size Included: Our baby bed crib screws bolts hardware kit includes 16pcs m6 x 16mm 40mm 60mm 80mm bolts and 16pcs m6x12…

- ❋ [Multiple Sizes]: The kit includes M6x40mmx15Pcs, M6x50mmx15Pcs, M6x60mmx10Pcs, M6x70mmx10Pcs, M6x80mmx10Pcs hex socke…

- ❋ [Reliable materials]: Our products are made by high-quality metal, anti-corrosive and anti-rust, it increase the servi…

- ❋ [Humanized Design]: The bolts have clear threads and smooth surfaces without burrs, which makes installation and disas…

- 1️⃣[ What You Get ]: The package includes 10pcs m6x20mm hex socket cap bolts ( length is 20mm, thread diameter is 6mm )….

- 2️⃣[ High-quality Material ]: The m6 countersunk bolt is made of high-standard carbon steel, strong and durable, high ha…

- 3️⃣[ Powerful Functions ]: The surface of furniture bolts adopts nickel plating process, which has anti-oxidation perfor…

- Pack of 12

- 5/8″ Height, 1/2″ Diameter, 5/16″-18 Threaded Center Hole

- Black, Powder Coated

Moving into the second section, it’s essential to explore detailed comparisons and practical applications of various Barrel Nuts. The market offers a diverse selection of these nuts, each engineered to meet specific performance criteria. Key factors to consider when choosing Barrel Nuts include material quality, load capacity, thread design, and ease of installation. For example, stainless steel Barrel Nuts are ideal for corrosive environments, while alloy steel variants may be better suited for high-load industrial applications.

Below are several important considerations for selecting the best Barrel Nuts:

- Material and Finish: High-quality stainless steel or alloy Barrel Nuts provide excellent durability and resistance to corrosion. Some models also feature chrome plating for enhanced aesthetic appeal.

- Design Variations: Options include low-profile Barrel Nuts for compact spaces and extended-thread models for higher load requirements. Variants with self-locking features are particularly useful in high-vibration applications.

- Load Capacity and Tolerance: The precision engineering behind Barrel Nuts ensures consistent performance even under heavy loads. Look for nuts that meet or exceed industry standards for tensile strength.

- Ease of Installation: Modern Barrel Nuts are designed for straightforward installation with standard tools. Detailed technical specifications and torque recommendations help prevent issues during assembly.

- Cost-Effectiveness: While premium Barrel Nuts might have a higher upfront cost, their superior performance and longer service life can result in overall savings through reduced maintenance and downtime.

Recent industry data suggests that the integration of precision-engineered Barrel Nuts in motion control systems can enhance efficiency by reducing friction losses and ensuring smoother operation. In a report featured on Fastener World, experts noted that systems equipped with quality Barrel Nuts show improved accuracy and reliability, which are critical in automated and high-precision environments.

Practical tips for installers include ensuring proper alignment between the Barrel Nut and the mating components. Misalignment can lead to uneven load distribution and premature wear. It is also advisable to use appropriate lubricants during installation to further reduce friction and protect the threads. Regular inspections and maintenance checks can help identify early signs of wear, thereby preventing costly failures. Expert recommendations emphasize the importance of following manufacturer guidelines to achieve optimal performance and durability from your Barrel Nuts.

Furthermore, the adaptability of Barrel Nuts makes them an excellent choice for both heavy industrial use and smaller-scale applications. In robotics, for instance, the precise motion control provided by Barrel Nuts is crucial for maintaining positional accuracy. In contrast, in furniture assembly or decorative installations, the clean, finished appearance of these nuts adds a professional touch while still delivering robust performance.

Innovative developments in Barrel Nuts technology continue to drive improvements in both functionality and efficiency. Manufacturers are investing in research to further reduce friction and enhance the self-locking capabilities of these nuts. This ongoing innovation ensures that Barrel Nuts remain at the forefront of fastener technology, offering solutions that are both reliable and cost-effective. Continuous improvements in material science and manufacturing processes have made it possible to produce Barrel Nuts with higher strength-to-weight ratios and improved performance under extreme conditions.

In terms of safety and reliability, Barrel Nuts are indispensable in applications where failure is not an option. Their robust construction and precise engineering ensure that joints remain secure even under dynamic loads and continuous operation. This level of reliability is especially critical in aerospace, automotive, and industrial machinery where even minor failures can lead to significant disruptions. By choosing high-quality Barrel Nuts, you invest in the longevity and safety of your assembly, ultimately enhancing overall system performance.

Understanding the technical nuances and practical applications of Barrel Nuts is essential for anyone involved in design, maintenance, or assembly of mechanical systems. Whether you are an engineer, a maintenance professional, or a DIY enthusiast, the insights provided in this guide can help you select the ideal Barrel Nuts to meet your specific needs. The detailed analysis, combined with expert recommendations and real-world data, offers a comprehensive resource that can significantly improve your fastener selections.

By integrating advanced design features, rigorous quality control, and practical installation tips, this guide aims to empower you to make informed decisions about Barrel Nuts. The strategic use of these fasteners can lead to improved system reliability, reduced maintenance costs, and enhanced overall performance. For those looking to upgrade or optimize their mechanical assemblies, high-quality Barrel Nuts are an investment that pays dividends in both functionality and safety.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”