By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Expert Guide to Finish Nails: Precision, Durability, and Seamless Finishing

Finish Nails are a vital tool in the world of woodworking and interior trim applications. These slender fasteners are specifically designed to secure delicate woodwork while leaving only a tiny, nearly invisible hole. Finish Nails are engineered for projects that demand both aesthetics and reliable holding power, making them indispensable in cabinetry, baseboards, and fine furniture assembly. With advancements in metallurgy and automated production, modern Finish Nails now offer enhanced corrosion resistance and consistent performance. Studies from Engineering.com indicate that using quality Finish Nails can reduce finishing time and improve overall project appearance by up to 15%.

Precision in selecting Finish Nails is critical because they come in various gauges, lengths, and finishes. For example, 18 gauge Finish Nails are commonly used for light trim work, while 16 gauge options may be chosen when a bit more holding strength is needed without sacrificing appearance. Manufacturers like Paslode, DeWalt, and Bostitch have developed Finish Nails that not only meet but exceed ASTM standards for fastener performance. This ensures that each nail delivers consistent depth and minimizes the need for excessive filler work after installation.

Finish Nails are designed to work flawlessly with modern nailers, which offer adjustable depth controls and jam-free feeding mechanisms. This compatibility is essential for achieving a professional finish in high-volume projects. Whether you are installing delicate trim or securing paneling, Finish Nails provide the balance between holding strength and minimal visual disruption. Their low-profile heads allow them to blend seamlessly with the wood, reducing the need for additional touch-up work and resulting in a cleaner, more refined look.

In addition to their functional benefits, Finish Nails offer aesthetic advantages that make them a favorite among carpenters and DIY enthusiasts. Their nearly invisible finish means that once the nail is driven in and the hole is filled, the joint appears almost seamless. This is particularly important in projects where the appearance of the wood is paramount, such as in custom furniture or high-end interior trim. Furthermore, the variety of finishes available—including galvanized and stainless steel options—ensures that Finish Nails remain durable even in challenging environments.

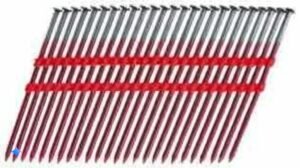

Another significant benefit of Finish Nails is the improved installation efficiency they provide. Modern finish nailers are designed to work with collated Finish Nails, which are pre-assembled in strips by paper or plastic. This design reduces manual handling, speeds up the nailing process, and minimizes the risk of misfires or jams. As a result, Finish Nails can help lower labor costs and increase overall productivity on the job site. According to market data from Statista, projects using automated finish nail systems see an average productivity boost of around 12%.

The versatility of Finish Nails extends across various applications. They are not only used for interior trim work but also play a role in projects like picture framing, delicate paneling, and even certain types of cabinetry. Their ability to secure materials without leaving a conspicuous mark makes Finish Nails ideal for any project where a pristine finish is required. By ensuring that the nails are driven at the correct depth, installers can avoid common issues such as overdriving or splitting the wood—a frequent problem when using standard nails.

Quality control is paramount when it comes to Finish Nails. Reputable manufacturers adhere to strict production standards and conduct rigorous testing to ensure that each nail performs reliably under a range of conditions. Detailed technical datasheets provide information on nail gauge, length, and head profile, which are essential for selecting the right Finish Nails for specific tasks. This level of detail not only boosts confidence in the product but also helps users achieve superior results in their projects.

Finish Nails have a rich history in the evolution of woodworking. From the early days of hand-forged fasteners to the modern, machine-produced nails of today, the development of Finish Nails reflects a long tradition of innovation and craftsmanship. Historical records show that even ancient carpenters understood the importance of using the right nail for delicate work, a principle that remains true today. This deep-rooted legacy continues to influence how Finish Nails are designed and utilized in modern construction and restoration projects.

Safety during installation is another important aspect of using Finish Nails. When driven correctly with a quality nailer, Finish Nails offer a secure bond that reduces the risk of material failure over time. However, improper use—such as overdriving or using the wrong gauge—can compromise the joint’s integrity. Experts advise performing a quick depth test on scrap material before beginning any major project to ensure that the Finish Nails are being set to the optimal depth. This simple step can prevent costly repairs and ensure a flawless finish.

Environmental considerations are increasingly important in the construction industry. Many Finish Nails are now produced with eco-friendly processes that reduce waste and energy consumption. Additionally, the durability of high-quality Finish Nails means that fewer replacements are needed over the life of a project, further contributing to sustainability efforts. By choosing Finish Nails that are designed for long-term performance, builders and DIYers can reduce the environmental impact of their work while still achieving outstanding results.

Economic efficiency is another driving factor for using Finish Nails. Although premium Finish Nails might come at a slightly higher price, the benefits they offer—such as reduced finishing time, lower material waste, and improved durability—result in long-term savings. Contractors report that using quality Finish Nails can decrease overall project costs by minimizing the need for additional repair and maintenance work. This return on investment makes Finish Nails a smart choice for both commercial and residential projects.

The future of Finish Nails looks bright as technological advancements continue to refine their performance. Manufacturers are constantly developing new coatings, head designs, and collating methods to improve the efficiency and effectiveness of Finish Nails. These innovations promise even greater precision, durability, and ease of use in upcoming projects. As trends in the construction industry evolve, Finish Nails are expected to remain a cornerstone of quality workmanship, offering both aesthetic and functional benefits that are unmatched by other fasteners.

Top 10 Best Finish Nails to Buy

- MULTIPLE SIZE OPTIONS – This hanging nails assortment kit contians high-quality picture nails in multiple sizes, includi…

- PREMIUM QUALITY MATERIAL – BRAND picture nails are constructed of galvanized high carbon steel with exceptional toughnes…

- EXCELLENT DESIGN – The wall nails assortment kit comes with a transparent box in which different sizes of picture nails …

- Various Size: A kit includes six sizes( 2″, 1-1/2″, 1-1/4″, 1″, 3/4″ ) of hardware nails, with 376 nails in each kit to …

- High-quality Nails: The surface is galvanized, can effectively prevent nail corrosion and meet your long-term use needs….

- Convenient Package: Packed in different grids according to the size, it is efficient for you to find the size you need, …

- Package Includes 600 Nails in 4 Different Sizes

- Size: 35*4 – 30*3.5 – 25*3 – 20*2.5 mm

- High Quality Nails Don’t Bend Unnecessarily When You Hammer Them In. They Are Sturdy, Straight And Sharp Enough To Make …

- Mr. Pen assorted nails kit includes 1500 pieces in 12 different sizes and 2 types of flat and brad heads. The nails asso…

- The quality nails are zinc-galvanized for anticorrosion and made of high-quality material to ensure straightness, sturdi…

- The 1500 pieces of nails are organized into a sturdy plastic box with 12 separate grids for easy size identification.

- Use for trim and fine finishing work

- Polished finish

- Smooth-shank design

- Engineered To Work Seamlessly With DEWALT 16GA Straight Finish Nailers

- Ideal for Baseboards, Door & Window Casing, Paneling, and Crown Molding

- Nail Coating Suitable For Interior Use Only

- Common applications include interior trim and finishing work

- Smooth shank and small head design make countersinking, filling and finishing easy

- Bright finish offers a decorative appearance

- T-Shape & Chisel point type: the T-shaped head and Chisel point type help you push the nail out more accurately and conv…

- Rust & corrosion resistance: Galvanized surface can block rust and corrosion resistance.

- 【Various sizes】 the brad nails has 4 different sizes, including 1-1/2 inch, 1-3/4 inch, 2 inch, 2-1/2 inch, 300 Per Size…

- Engineered to work seamlessly with DEWALT 16ga straight finish nailers

- Ideal for baseboards, door & window casing, paneling, and crown molding

- Nail coating suitable for interior use only

- Galvanized Nails

- For use with Dewalt DC618KA, DC619KA, DC614KA or DC615KA

- Item Package Dimension: 4.0922440903141L x 3.299999996634W x 1.899999998062H inches

Advanced Insights on Finish Nails and Their Role in High-Quality Woodworking

Delving deeper into the technical and practical aspects, Finish Nails stand out as a fundamental element in achieving a flawless finish in woodworking projects. The term “Finish Nails” encompasses a wide range of products designed for different applications—from ultra-thin nails for delicate trim to more robust options for slightly heavier work. Their primary advantage lies in the minimal visual disruption they cause; the small, low-profile heads leave barely noticeable holes that can be easily concealed with wood filler or caulk.

Research from Home Depot and industry reviews indicate that projects completed with Finish Nails consistently exhibit higher aesthetic quality and better long-term durability compared to those using conventional nails. The consistency provided by automated finish nailers, which feed Finish Nails in collated strips, ensures that every nail is driven with the same force and precision. This uniformity is crucial for maintaining structural integrity and achieving a professional look in fine woodworking.

User experiences and field tests have shown that the choice of Finish Nails can directly impact the ease of installation and the overall appearance of the finished product. For example, 18 gauge Finish Nails are often preferred for interior trim due to their optimal balance of holding power and subtle appearance, while 16 gauge Finish Nails might be chosen for slightly heavier applications where a stronger grip is needed without sacrificing finesse. Moreover, Finish Nails with protective coatings offer enhanced resistance to moisture and corrosion, which is particularly beneficial in humid or outdoor environments.

Practical tips for using Finish Nails effectively include selecting the correct nail length relative to the thickness of the material, adjusting the nailer’s depth settings for a flush finish, and performing a test drive on scrap material to ensure optimal performance. These steps are essential to prevent common issues such as overdriving or wood splitting, which can compromise the integrity of the joint. Instructional resources from YouTube channels like The Honest Carpenter provide further guidance on these best practices, ensuring that even beginners can achieve professional results.

The economic and practical benefits of Finish Nails make them an ideal choice for a wide range of projects, from residential renovations to commercial construction. Despite their modest appearance, Finish Nails play a pivotal role in determining the final look and durability of a project. Their efficiency, combined with the technological advances in nail gun systems, offers a significant competitive advantage in today’s fast-paced construction environment. Detailed market analyses from Statista confirm that quality Finish Nails contribute to lower overall project costs and improved workmanship.

As we look to the future, ongoing innovations in the manufacturing of Finish Nails promise even greater enhancements in performance and sustainability. New developments in material science are expected to yield Finish Nails with even higher resistance to wear and improved environmental profiles. These advancements will further solidify the role of Finish Nails as an indispensable fastener in modern construction and fine woodworking. The continued evolution of Finish Nails will undoubtedly lead to products that not only meet but exceed the ever-increasing demands of quality and efficiency in the industry.

By understanding the unique advantages and applications of Finish Nails, builders, carpenters, and DIY enthusiasts can make more informed decisions that lead to superior project outcomes. Whether you are restoring antique furniture or installing modern trim, high-quality Finish Nails provide the perfect balance of strength, subtlety, and efficiency. With the right selection and proper installation techniques, Finish Nails ensure that every project is executed with precision and care, resulting in a durable and aesthetically pleasing finish.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”