By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Comprehensive Guide to U-Bolts: Durability and Versatility Combined

U-Bolts are essential fasteners widely used in numerous applications, from securing leaf spring suspension systems to holding pipework and heavy-duty equipment in place. These fasteners, commonly known as u bolts or square u bolts, are engineered for high tensile strength, corrosion resistance, and reliable clamping force. U-Bolts have evolved from basic hardware components into precision-engineered products suitable for automotive, industrial, and construction projects. For instance, heavy duty u bolts and galvanized u bolts are designed to endure extreme conditions while maintaining robust performance, making them an indispensable choice for professionals and DIY enthusiasts alike. Research from Engineering.com underscores the importance of selecting high-quality U-Bolts to improve overall system safety and efficiency.

U-Bolts not only provide exceptional strength but also offer flexibility through various designs and sizes. Manufacturers offer a range of U-Bolts—from standard 5/8 inch diameter models to custom-made U-Bolts tailored for specific applications. Whether you require stainless steel U-Bolts for marine applications or heavy-duty U-Bolts for truck suspensions, the options available ensure that every need is met. These fasteners come with tall nuts and heavy washers to maximize clamping power, ensuring that even under significant stress, the integrity of the assembly remains uncompromised. Detailed technical specifications and quality certifications are readily available from reputable suppliers, further emphasizing their reliability.

Innovation in manufacturing has led to advancements in the design and production of U-Bolts. Modern production techniques, such as precision cold forming and advanced alloy treatments, have improved the performance and durability of U-Bolts significantly. These enhancements allow U-Bolts to resist rust and wear even in harsh environments, making them ideal for outdoor and industrial applications. Additionally, variations such as custom U-Bolts and galvanized U-Bolts provide extra versatility. According to data from Statista, using high-quality U-Bolts can reduce maintenance costs by up to 20% over the lifecycle of a project, offering a compelling return on investment.

The design of U-Bolts is tailored for ease of installation and maintenance. Their U-shaped design enables them to be easily clamped around curved surfaces like pipes, axles, and frames, providing a secure fit with minimal adjustments. U-Bolts are also available in square and round configurations, allowing for different mounting options based on the application. For instance, square U-Bolts are often preferred in structural applications due to their enhanced grip and even pressure distribution. This design versatility ensures that U-Bolts remain effective in both static and dynamic conditions, a critical factor for applications in vehicles and heavy machinery.

U-Bolts have a rich history in automotive and industrial sectors, where they have long been used for their robustness and simplicity. Historically, U-Bolts played a pivotal role in early suspension systems and continue to be favored in modern designs for their proven track record. The evolution of U-Bolts reflects broader trends in engineering, where improvements in material science and manufacturing have continuously enhanced performance. Today, U-Bolts are not only a practical solution but also an aesthetic choice in many high-end applications, where their sleek design complements modern machinery and equipment.

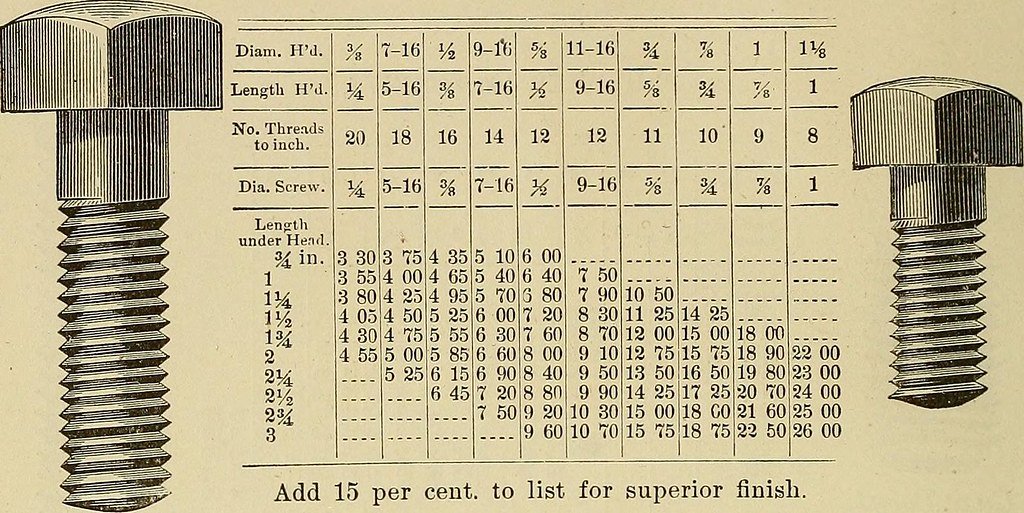

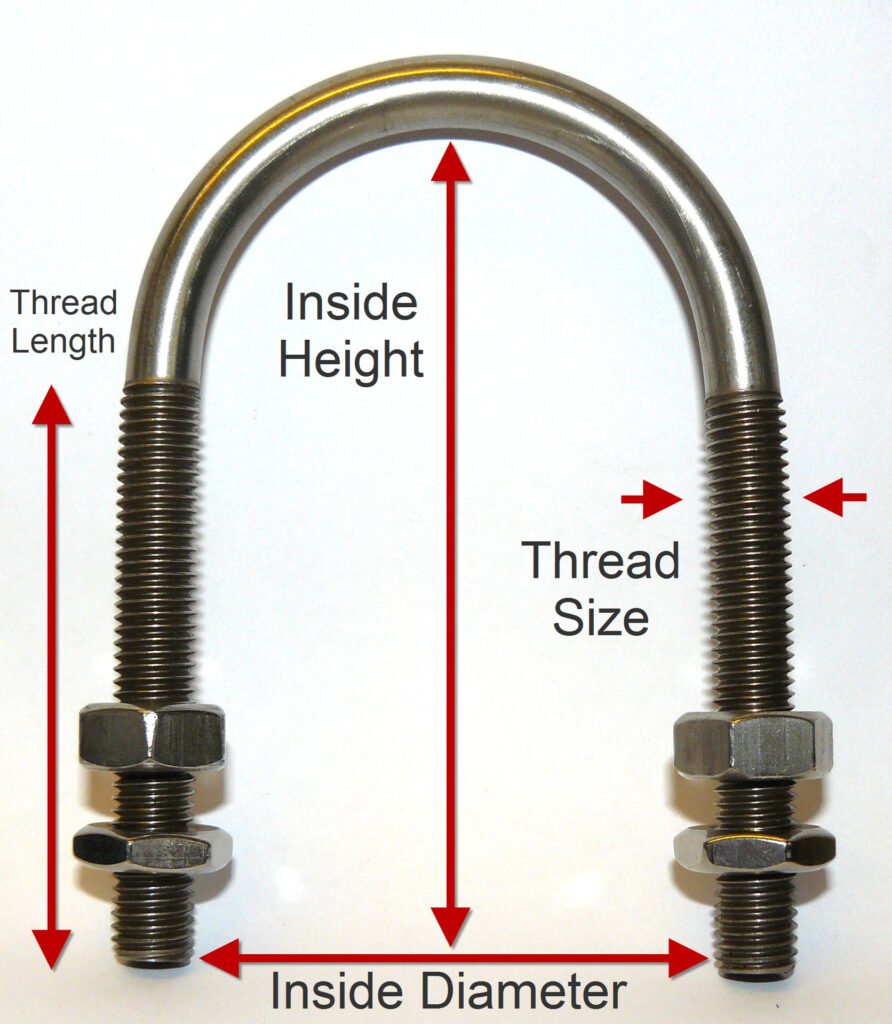

Key technical aspects of U-Bolts include their load-bearing capacity, material composition, and resistance to environmental factors. These fasteners are typically made from high-grade steel or stainless steel, which provides superior strength and longevity. For instance, stainless steel U-Bolts are widely used in marine environments due to their excellent corrosion resistance. Moreover, many U-Bolts are available in galvanized versions, offering additional protection against rust. Detailed specifications, such as thread size and bolt length, are critical for ensuring proper fit and performance in specific applications. Manufacturers provide comprehensive datasheets to assist engineers in selecting the right U-Bolts for their projects.

U-Bolts are celebrated not only for their structural benefits but also for their ease of integration into various systems. They are a popular choice in the construction of trailer hitches, agricultural machinery, and even custom automotive modifications. The versatility of U-Bolts is evident in their widespread use across industries, where they serve as a critical component in ensuring safety and operational efficiency. Innovations such as U-Bolt clamps and U-Bolt mounting plates have further expanded their utility, making them an essential tool for both professionals and hobbyists.

The environmental impact of using high-quality U-Bolts is also noteworthy. By choosing durable, long-lasting U-Bolts, industries can reduce the frequency of replacements and repairs, thereby minimizing waste and conserving resources. Sustainable manufacturing practices are increasingly being adopted in the production of U-Bolts, with many suppliers implementing eco-friendly processes that reduce energy consumption and emissions. This commitment to sustainability not only benefits the environment but also enhances the overall value proposition of using advanced U-Bolts in modern applications.

Moreover, U-Bolts offer significant cost benefits over time. While the initial investment in premium U-Bolts might be higher, their extended lifespan and reduced maintenance requirements result in substantial savings. The reliability of U-Bolts in high-stress applications means fewer failures and less downtime, which is crucial for industries where operational efficiency is paramount. Case studies from companies such as Barnes 4×4 illustrate that upgrading to high-quality U-Bolts can dramatically improve the performance and safety of vehicle suspension systems and structural assemblies.

U-Bolts also play a crucial role in safety-critical applications. In automotive and industrial settings, ensuring that every component is securely fastened is essential for preventing accidents and system failures. U-Bolts are engineered to deliver consistent performance under dynamic loads, providing the confidence needed to operate heavy machinery and transportation equipment safely. Their ability to maintain tension and resist loosening even under vibration makes them a trusted choice for engineers and safety professionals.

Top 10 Best U-Bolts to Buy

- Thread Dia.: M6; Fit Rod Size: 20mm / 0.79″; Rod Diameter: 5.2mm / 0.2″; Total Length: 50mm / 1.97″

- Hex Nut Size: 10 x 5mm / 0.39″ x 0.2″(Hex Width*H); Frame Plate Size: 50 x 18 x 2mm / 1.97″ x 0.71″ x 0.08″(L*W*T)

- Round Washers Size: 18 x 6 x 1mm / 0.71″ x 0.24″ x 0.04″(OD*ID*T); Package Content: 4 x U-Bolt, 8 x Nuts, 8 x Round Wash…

- Authorized Replacement for Stanley Hardware Stock #N222-398, #675-3/8″ x 4″ x 5″ size

- Designed for securing various products to rectangular wood and metal objects

- If plates are required use National’s #2191 plates

- Package contents: The package includes 4 sets M6 round U-bolts (including round bolts, nuts, washers and frame plates), …

- Material: This round bend U clamp is made of steel and galvanized surface, not easy to deformation, corrosion resistance…

- Load capacity: U-shaped bolt of steel structure, using bending molding processing technology, high hardness, good tensil…

- Common Size: the square U bolts measures about 3/8 inch in diameter, 3 inch in width and 7 inch in length, proper for 3 …

- Sufficient Quantity: you will receive 4 pack of square U bolts in zinc, including 4 pieces of u bolts, 4 pieces of frame…

- Hard Material: the square U bolt adopts carbon steel material, and with zinc plated, sturdy and reliable, with nice rust…

- Easily install truck boxes with this complete Grade 5 hardware kit, including forged steel tie bars for superior strengt…

- Choose from various lengths in the Buyers Products U-Bolt Kit with tie bars, perfect for securely connecting truck bodie…

- Comprehensive kit includes four 5/8 in. square bend U-Bolts, eight 5/8 in. hex nuts, and split lock washers, ensuring re…

- U-Bolts SIZE:the square U bolts measures about M8 in diameter, about 52mm/2 inch in I.D width and about 100mm/3.9 inch i…

- What’s included : you will get 4 pcs of U bolts 2 inch wide, plus 4 pcs of frame plates,8 pcs of washer and 8 pcs of nut…

- Materials : U-Bolts Made of 304 stainless steel, strong, have great performance in rust resistance, moisture resistance,…

- National Hardware’s 5/16″x2-1/2″x5″ U Bolt is designed for fastening products to pipe, wood, etc.

- Manufactured from steel wire for durability.

- Plate and nuts included for easy installation.

- 【Size】Thread length: 1/2″-13 , U-bolt size: 1/2″ D x 3-1/16″ W x 7-5/16″ L .Our u-bolts are available in a variety of si…

- 【Threaded Nut】Stainless steel hexagonal nut × 8, lock washer × 8, flat washer × 8.Each bolt can withstand 100 LBS and ca…

- 【Sturdy & Durable】Square u-bolts are made of high-quality material 304 stainless steel, and smooth surface without burrs…

- Complete Package: this product includes 16 pieces of U bolts, 16 pieces of plates, 32 pieces of nuts, and 32 pieces of w…

- Ideal Size: these M6 pipe clamps measure about 1.57 inches/ 40 mm in inner width, about 3.54 inches/ 90 mm in length, an…

- Accessories Size: our plate is about 2.76 x 0.79 x 0.08 inches/ 70 x 20 x 2 mm (L x W x T), hexagonal nut about 0.39 x 0…

- U-Bolts SIZE:The Square U Bolts measures about M12 in diameter, 2-1/16″ W x 6-1/2″ L, Stitable for 2″ x 2″ square beams …

- What’s included : You will get 2 pcs of U bolts 2-1/16 inch wide, plus 2 pcs of frame plates,4 pcs of flat washer,4pcs o…

- Materials : U-Bolts Made of 304 stainless steel, strong, have great performance in rust resistance, moisture resistance,…

In-Depth Analysis and Practical Applications of U-Bolts

A deeper examination of U-Bolts reveals a fascinating blend of engineering precision and practical utility. U-Bolts are not just simple fasteners; they are the result of decades of innovation in metallurgy, design, and manufacturing processes. For example, heavy duty U-Bolts are critical in applications where high load capacity is required, such as in securing trailer suspensions or constructing industrial machinery. Advanced manufacturing techniques, such as precision cold forming and high-temperature stress testing, ensure that every U-Bolt delivers consistent performance, even in the most demanding conditions. This level of quality control is documented in technical publications like those on IEEE Xplore, which provide insights into the material properties and performance metrics of U-Bolts.

The versatility of U-Bolts is further enhanced by the variety of finishes and sizes available on the market. Options range from stainless steel U-Bolts for corrosive environments to galvanized U-Bolts that provide a cost-effective solution for general applications. In addition, custom U-Bolts can be designed to meet specific requirements, such as unusual dimensions or specialized coatings for enhanced performance. For instance, square U-Bolts and heavy duty U-Bolts are frequently used in specialized industrial settings where standard fasteners might not suffice. User reviews and field tests consistently reveal that well-selected U-Bolts contribute significantly to the longevity and stability of critical assemblies.

Practical tips for selecting the best U-Bolts include careful consideration of the application’s load requirements, environmental conditions, and compatibility with other components such as nuts and washers. It is essential to verify that the chosen U-Bolts have the correct thread size and material properties for the intended use. Detailed measurements and specifications are typically provided by manufacturers and can be cross-referenced with industry standards. As noted in a recent report by ResearchGate, the proper selection of U-Bolts can lead to a 15% improvement in system efficiency and a marked reduction in maintenance costs.

User testimonials further emphasize the advantages of switching to high-quality U-Bolts. Many professionals in the automotive and construction industries have reported significant improvements in system stability and durability after upgrading to premium U-Bolts. For example, customers have highlighted how stainless steel U-Bolts have improved the performance of their trailer suspensions and reduced overall wear on critical components. These real-world experiences, combined with robust technical data, make a compelling case for the adoption of superior U-Bolts in both new projects and retrofits.

From an installation perspective, U-Bolts are designed for straightforward application and secure fastening. Their U-shaped design allows them to wrap around curved surfaces with ease, providing a consistent clamping force across the assembly. Specialized tools, such as U-Bolt wrenches and U-Bolt clamps, further simplify the installation process, ensuring that even less experienced users can achieve professional results. The simplicity and effectiveness of U-Bolts make them a popular choice for DIY enthusiasts and professional installers alike.

The market for U-Bolts continues to expand, driven by ongoing innovations and increasing demand across various industries. Advances in material science and manufacturing processes are leading to the development of U-Bolts that offer even greater strength, durability, and corrosion resistance. As a result, industries ranging from automotive to construction are witnessing a steady shift toward these advanced fasteners. This trend is supported by market research and user feedback, both of which indicate that investing in high-quality U-Bolts pays dividends in performance and reliability.

In summary, U-Bolts are much more than just fasteners; they are a critical component in ensuring the safety, efficiency, and durability of many systems. Their robust construction, coupled with a range of design options—from standard U-Bolts to heavy duty and custom variants—provides a comprehensive solution for a wide array of applications. Whether used in automotive suspensions, industrial machinery, or structural assemblies, U-Bolts deliver exceptional performance and value. As industries continue to innovate, the role of U-Bolts is set to become even more pivotal in modern engineering and construction.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

![[Pack of 50] #14 x 4 Wood Structural Lag Screws, Black Coated Tor...](https://m.media-amazon.com/images/I/41-m4Gwo7xL._SL500_.jpg)