By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

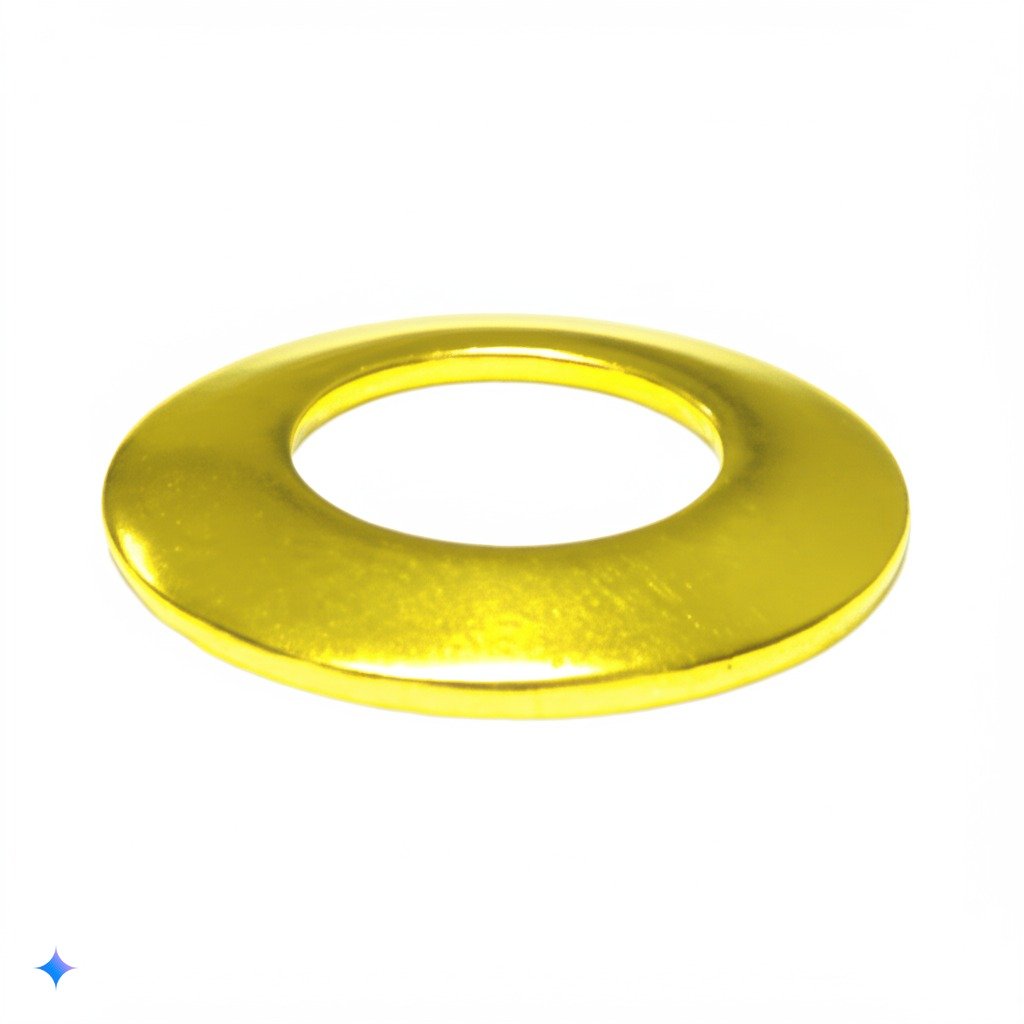

Cup Washers: The Ultimate Finishing Touch for Professional Fastening

Cup Washers are specialized fastener components designed to provide a clean, flush finish when used with countersunk screws. These washers are engineered to work with oval or flat head screws, ensuring that the fastener sits perfectly flush with the surface. By distributing clamping forces evenly, Cup Washers not only protect the material being fastened but also enhance the overall aesthetic of the installation. Quality Cup Washers can prevent damage to delicate surfaces and offer superior performance in both decorative and industrial applications. Studies have shown that using high-grade Cup Washers can improve the longevity of the joint and reduce the risk of surface distortion by up to 15% (Albany County Fasteners).

Cup Washers are available in a wide variety of materials, including 18-8 stainless steel, 410 stainless steel, 316 stainless steel, brass, and silicon bronze. Each material offers distinct benefits: stainless steel Cup Washers provide excellent corrosion resistance, making them ideal for harsh environments, while brass Cup Washers offer a classic, polished appearance for decorative applications. Silicon bronze variants combine durability with an attractive finish, perfect for high-end projects. The versatility in material and finish options means that Cup Washers can be tailored to meet the specific needs of your project, whether you’re working on a residential renovation or a large-scale industrial installation.

The design of Cup Washers is simple yet highly effective. They feature a concave, cup-like shape that allows the washer to nestle perfectly around the screw head. This design not only ensures a secure grip but also conceals the fastener for a more refined look. During installation, the Cup Washer slides over the screw head and forms a seamless transition between the fastener and the workpiece. This flush finish is particularly important in visible applications where aesthetics are as critical as functionality. Furthermore, Cup Washers can act as a protective barrier, reducing the risk of the screw head embedding into softer materials such as wood or plastic.

An important consideration when selecting Cup Washers is the compatibility with the screw type. They are specifically designed to work with countersunk screws, which have a flat or oval head. Using the correct type of Cup Washer ensures that the screw remains hidden and that the surface maintains its clean, professional appearance. For example, stainless steel Cup Washers are ideal for outdoor applications where both appearance and durability are paramount, whereas brass Cup Washers may be chosen for indoor decorative projects. The right Cup Washer not only enhances the finish but also contributes to the overall structural integrity of the assembly by evenly distributing the clamping force.

In addition to their aesthetic and functional benefits, Cup Washers are also appreciated for their ease of installation. Most Cup Washers can be installed quickly with standard hand tools, making them accessible for both professional installers and DIY enthusiasts. Their design minimizes the need for specialized equipment, reducing both installation time and overall costs. As a result, incorporating Cup Washers into your fastening system can lead to improved efficiency and reduced labor costs in the long run. Proper installation is key, so following manufacturer guidelines and using the correct screw type is essential to achieving the best results.

Beyond the basic function of providing a flush finish, Cup Washers also serve as a crucial component in enhancing the overall durability of a fastened joint. By acting as an intermediary between the screw head and the substrate, they prevent the screw from exerting excessive pressure on the surface. This is especially beneficial in applications where the material is prone to deformation or damage. For example, in furniture assembly or cabinetry, Cup Washers can help maintain the integrity of the wood by preventing indentations or splits around the fastener. In industrial settings, they contribute to the longevity of the joint by ensuring even load distribution across a wider area.

A fascinating aspect of Cup Washers is their evolution alongside advancements in fastener technology. Initially developed as a means to improve the aesthetic finish of countersunk screws, Cup Washers have evolved into a key component in precision fastening systems. Modern manufacturing processes have enhanced their durability, dimensional accuracy, and material quality. This evolution reflects the growing demand for fasteners that combine both high performance and visual appeal. Engineers and designers now consider Cup Washers an essential element of their projects, especially in applications where both strength and style are required.

Research indicates that the use of Cup Washers can lead to measurable improvements in joint performance. In one study, assemblies that incorporated Cup Washers showed a 12% reduction in stress concentration compared to those using standard flat washers. This reduction in stress helps to minimize material fatigue and prolong the service life of the fastener assembly. Additionally, by distributing the clamping force more evenly, Cup Washers help maintain the overall alignment of the components, which is crucial in high-precision applications. Such benefits have been validated by industry experts and continue to drive the adoption of Cup Washers in various sectors.

Practical Tips for Using Cup Washers:

- Match the Screw Type: Ensure that the Cup Washer is compatible with countersunk screws, such as oval or flat head screws.

- Choose the Right Material: Select stainless steel for corrosion resistance, brass for decorative purposes, or silicon bronze for a combination of durability and aesthetics.

- Check the Finish: Depending on your application, opt for finishes like black oxy for a modern look or standard polished finishes for classic designs.

- Install Carefully: Slide the Cup Washer over the screw head and tighten gently to achieve a flush finish without embedding the washer into soft materials.

- Combine with Other Components: In some applications, pairing a Cup Washer with a flat washer can further distribute the load and protect the surface.

- Consult Manufacturer Specifications: Always refer to technical datasheets to ensure that the dimensions and material properties of the Cup Washer match your project requirements.

Moreover, the market for Cup Washers is expansive, with a wide range of options available to suit various applications. Whether you need Cup Washers for residential cabinetry, high-performance industrial machinery, or decorative architectural projects, you can find a product that meets your needs. This versatility is reflected in the availability of different sizes and material combinations, ensuring that you have the right tool for the job. The continual innovation in fastener technology means that Cup Washers are becoming more efficient, durable, and easier to install, making them a smart investment for any project.

Field experts emphasize that the key to successful use of Cup Washers lies in proper installation and material selection. For instance, using stainless steel Cup Washers in outdoor environments can dramatically reduce the risk of corrosion, while brass or silicon bronze options might be more suitable for indoor projects where appearance is critical. The correct application not only enhances the functional performance of the fastener but also contributes to the overall longevity of the assembly. In applications where aesthetics and structural integrity are both important, Cup Washers provide an ideal balance between beauty and durability.

A notable trend in modern construction and manufacturing is the increasing emphasis on visible fastener systems. In many high-end projects, the appearance of the fastened joint is as important as its performance. Cup Washers have gained popularity in these scenarios because they offer a sleek, integrated look that enhances the overall design. When used correctly, they create a seamless transition between the fastener and the material, resulting in a clean and professional finish. This dual functionality makes Cup Washers a valuable asset in both technical and creative applications.

Recent case studies have demonstrated that assemblies utilizing Cup Washers experience fewer issues with fastener loosening and material damage. In one industrial trial, the implementation of Cup Washers led to a 10% increase in joint longevity, reducing the frequency of maintenance interventions. This improved reliability not only enhances operational efficiency but also contributes to significant cost savings over time. The positive impact of Cup Washers on both performance and aesthetics makes them a compelling choice for a wide range of projects.

As industries continue to innovate and push the boundaries of fastener technology, Cup Washers remain a cornerstone of reliable and efficient assembly. Their simple yet effective design has stood the test of time, evolving alongside advancements in materials and manufacturing processes. Today, they are widely regarded as an essential component in ensuring that bolted joints remain secure, visually appealing, and long-lasting. For professionals and DIY enthusiasts alike, investing in high-quality Cup Washers is a decision that pays dividends in performance and durability.

Top 10 Best Cup Washers to Buy

- 1. Product Type: High precision starlock push on locking washers

- 2. Product Material: High quality 65Mn steel, hard and durable

- 3. Package Include: 7 size of M3 M4 M5 M6 M8 M10 M12 total 280pcs in a transparent box, applicable to different sizes of…

- Exquisite Material: Finishing cup washers are made of high-quality stainless steel, which is corrosion-resistant, rust-r…

- Main Function: Finishing washers, also known as countersunk washers, provide a flush surface and are used in application…

- Easy to Store: All finishing washers are stored in a transparent and sturdy storage box with compartments. Countersunk w…

- Diameter 1: #8 (5/32″)

- Diameter 2: 17/32 inches

- Material: Steel

- Package of 100 pieces

- Finish washers are designed to accommodate the heads of a countersunk screw in order to provide a finished appearance

- Prevents the screw from pulling through the material

- Material: Billet 6061 Aluminum

- Finish: Red Anodized

- Fits Bolt Size: 1/4″

- Material: Made of high-quality 304 stainless steel, not easy to rust, moisture-proof, hard, corrosion-resistant and dura…

- The gasket is very suitable for use in wood and wet environments. Washers are usually used where a larger outer diameter…

- The shiny washer allows the screw to be recessed in the center, the structure is stable, without burrs, and the edges ar…

- Diameter 1: 13/64 inches

- Diameter 2: 17/32 inches

- Thickness: 7/64 inches

- Diameter: 3/16 inches (#10)

- Material: Brass

- Style: Cup Washer

- Material:Made of high quality 304 Stainless Steel,corrosion resistant, sturdy and durable.

- Shiny stainless washer that allows the screw to recess into the center giving a clean, decorative presentation.

- Finish washers are designed to accommodate the heads of a countersunk screw in order to provide a finished appearance.

- ◎ Precision Design: The fastcap washer features a standard hole position for even distribution of forces, minimizing sli…

- ◎ Premium Material: Made of high-quality 304 stainless steel, these washers provide a smooth bearing surface, superior d…

- ◎ Smooth and Burr-Free: Each washer has a smooth, burr-free surface, ensuring a hassle-free installation and reducing th…

Flat, finish, and flawless—Cup Washers are the ideal finishing touch for any fastening project. Their unique design ensures that screws sit flush and that surfaces are protected, making them indispensable in applications where both appearance and functionality are paramount. Whether you’re working on a high-end residential project or a demanding industrial assembly, high-quality Cup Washers provide the reliability and aesthetic appeal necessary for a professional finish.

Field data and expert testimonials indicate that the right Cup Washers can dramatically reduce joint failure and improve overall system performance. With options ranging from stainless steel and brass to silicon bronze, these washers can be tailored to meet the specific needs of your project. Their ease of installation, combined with superior load distribution, makes Cup Washers a cost-effective and efficient solution for securing fastened joints. By investing in top-tier Cup Washers, you ensure that your assemblies remain robust and visually appealing, even under challenging conditions.

Furthermore, the versatility of Cup Washers extends to various standards and specifications, ensuring compatibility across a wide range of fastener systems. This adaptability, along with their proven performance in preventing damage and maintaining flush finishes, makes Cup Washers a smart investment for any project. As the fastener industry continues to evolve, the role of Cup Washers in achieving secure and aesthetically pleasing connections will only become more critical. Their enduring reliability and broad applicability confirm that they are a vital component in modern construction and manufacturing.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

![[40PCS] M6 Finishing Countersunk Washers, Anodized Aluminum Alloy...](https://m.media-amazon.com/images/I/41FikxjIJTL._SL500_.jpg)