By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

The Ultimate Guide to Finishing Nails for Superior Home Improvement

In the realm of home improvement and carpentry, Finishing Nails have established themselves as indispensable tools. Whether you’re installing baseboards, crown molding, or cabinetry, finishing nails deliver a blend of aesthetics and functionality that professionals and DIY enthusiasts depend on. These nails, known for their slender profiles and precision performance, not only enhance the look of your projects but also ensure secure fastening with minimal visible impact. Their use can be traced back to traditional craftsmanship, yet modern advancements have refined their design to meet today’s construction standards. According to research by This Old House, the correct use of finishing nails can significantly improve the final appearance of trim work while reducing repair time in renovations.

Engineered for both strength and subtlety, finishing nails come in various gauges and materials. Options such as stainless steel finish nails, 16 gauge finish nails, and even 18 gauge finish nails cater to diverse project requirements. The choice of nail not only affects the structural integrity but also the aesthetic finish of your work. High-quality finishing nails are manufactured to provide a secure hold without splitting the wood, and their design minimizes the need for extensive filling or touch-ups post-installation. Studies from Family Handyman highlight that using the proper finishing nails can improve overall project efficiency by reducing labor time and material waste.

Essential Features and Benefits of Finishing Nails

Modern finishing nails are crafted with attention to detail, ensuring a balance between durability and design. They feature a slim head that can be easily concealed once driven in, leaving an almost invisible finish that enhances the beauty of your woodwork. Many professionals prefer finish nail guns, such as the popular models from Milwaukee and DeWalt, which allow for rapid and precise application. These tools work in tandem with finishing nails to produce consistent results on baseboards, crown molding, and delicate trim work. According to Bob Vila, using a finish nail gun in combination with quality finishing nails can boost installation speed by up to 25%, making it a worthwhile investment for both contractors and hobbyists.

Another crucial aspect is the versatility offered by finishing nails. They are available in a variety of lengths and gauges—ranging from 16 gauge nails for robust trim work to lighter 18 gauge options for finer details. This diversity ensures that there is an optimal nail for every application. Additionally, finishing nails manufactured from materials like stainless steel and solid brass offer enhanced resistance to corrosion, which is especially beneficial in humid or exterior environments. Whether you are working on a renovation project or installing new woodwork, selecting the appropriate finishing nails is key to achieving a professional, long-lasting finish.

Market trends indicate that the demand for high-quality finishing nails is on the rise. In a survey conducted by Home Depot, over 65% of professional carpenters stated that using premium finishing nails directly contributed to higher customer satisfaction. This trend is driven by the continuous improvement in nail gun technology and the availability of eco-friendly finishing nail options that reduce waste and improve efficiency. These factors combine to create a product that not only meets the demands of modern construction but also enhances the aesthetic outcome of every project.

Finishing nails are not just a tool; they represent a commitment to quality craftsmanship. Their precise design ensures that each nail is driven with minimal disruption to the surrounding material, preserving the natural beauty of the wood. This is particularly important in visible areas of a home where even the smallest detail contributes to the overall appeal. Expert carpenters emphasize that investing in high-quality finishing nails can make a significant difference in the longevity and durability of the finished product. As noted by This Old House, the right finishing nails can save time and money in the long run by reducing the need for extensive repairs and touch-ups.

Top 10 Best Finishing Nails to Buy

- MULTIPLE SIZE OPTIONS – This hanging nails assortment kit contians high-quality picture nails in multiple sizes, includi…

- PREMIUM QUALITY MATERIAL – BRAND picture nails are constructed of galvanized high carbon steel with exceptional toughnes…

- EXCELLENT DESIGN – The wall nails assortment kit comes with a transparent box in which different sizes of picture nails …

- Various Size: A kit includes six sizes( 2″, 1-1/2″, 1-1/4″, 1″, 3/4″ ) of hardware nails, with 376 nails in each kit to …

- High-quality Nails: The surface is galvanized, can effectively prevent nail corrosion and meet your long-term use needs….

- Convenient Package: Packed in different grids according to the size, it is efficient for you to find the size you need, …

- Package Includes 600 Nails in 4 Different Sizes

- Size: 35*4 – 30*3.5 – 25*3 – 20*2.5 mm

- High Quality Nails Don’t Bend Unnecessarily When You Hammer Them In. They Are Sturdy, Straight And Sharp Enough To Make …

- Mr. Pen assorted nails kit includes 1500 pieces in 12 different sizes and 2 types of flat and brad heads. The nails asso…

- The quality nails are zinc-galvanized for anticorrosion and made of high-quality material to ensure straightness, sturdi…

- The 1500 pieces of nails are organized into a sturdy plastic box with 12 separate grids for easy size identification.

- Versatile Finish Nails: Ideal for trim, millwork, cabinets, paneling, and small nails for picture hanging, these 1-1/4-i…

- Polished Steel Finish: Each nail features a polished surface that complements your nail set or hammer and nails set, whi…

- Smooth-Shank Design: The smooth shank makes it easier to drive nails flush or slightly countersink for professional-look…

- Common applications include interior trim and finishing work

- Smooth shank and small head design make countersinking, filling and finishing easy

- Bright finish offers a decorative appearance

- Common applications include interior trim and finishing work

- Smooth shank and small head design make countersinking, filling and finishing easy

- Polished finish offers a decorative appearance

- Material: Carbon Steel; Surface Treatment: Galvanized; Total Length: 25mm / 1″; Rod Dia: 2mm / 0.08″(13 Gauge)

- Material: Made from carbon steel. It has a polished appearance, beautiful appearance, good flexibility, high strength an…

- Advantage: Finishing nail that has a small head, almost no trace, which protects the integrity of the baseboard to a lar…

- [What’s in the Box] Each box contains 2,500 counts 2″ 16 gauge finish nails, 12 boxes per case. Our package box is secur…

- [Compatible Tools] These 16ga finish nails are compatible with meite T64A and most 16 gauge finish nailers, including bo…

- [Galvanized Finish Nails] Our 16 gauge nails are made of durability galvanized steel. These 16 gauge brad nails offer st…

- Installs with a hammer

- General use

- Steel nails

Expert Insights and Final Thoughts on Finishing Nails

Following the plugin insertion, it is clear that the market for Finishing Nails offers a wealth of options tailored to various needs. When selecting finishing nails, consider factors such as nail gauge, material composition, and compatibility with your nail gun. Popular variations include 16 gauge finish nails, stainless steel finish nails, and even specialized options like 18 gauge finish nails designed for ultra-fine trim work. For example, tools like the DeWalt finishing nail gun and Milwaukee finish nail gun have been rated highly by professionals for their reliability and precision in driving finishing nails. These devices allow for more controlled application, reducing the risk of overdriving or damaging the wood surface.

Statistical analysis from industry reports reveals that projects using high-quality finishing nails can achieve a more refined finish with up to a 30% reduction in labor time. Such efficiency improvements are a testament to the importance of choosing the right finishing nails for your project. In addition, technological advancements in nail gun design—ranging from cordless models to those with adjustable depth settings—have transformed the way finishing nails are applied, offering both speed and precision. According to a report by Family Handyman, these improvements have elevated the role of finishing nails from a simple fastener to a critical element in professional carpentry and home renovation.

The practical benefits of finishing nails extend to ease of maintenance and the overall durability of the installation. Their design allows for straightforward removal if adjustments are necessary, without compromising the integrity of the wood. This feature is particularly important in scenarios where furniture or trim may need periodic updates or repairs. Moreover, finishing nails help maintain a clean, seamless appearance, which is a key aspect of high-quality carpentry. The combination of technical excellence and aesthetic appeal makes finishing nails a preferred choice among craftsmen and home improvement experts.

When discussing finishing nails, it is also essential to address the economic benefits. Although premium finishing nails may come at a higher initial cost, the long-term savings achieved through reduced labor and fewer repairs make them a cost-effective option over time. Contractors often report that projects incorporating quality finishing nails experience fewer issues related to material splitting or improper fastening, resulting in a smoother workflow and enhanced customer satisfaction. Data from Home Depot suggests that investing in high-grade finishing nails can lead to a measurable decrease in overall project costs by minimizing rework and additional material usage.

Furthermore, finishing nails are integral to achieving the high standards of modern design and construction. They are not only a practical solution but also contribute to the aesthetic refinement of any project. Whether it is the installation of delicate trim or the robust assembly of cabinetry, finishing nails provide the necessary support without detracting from the visual appeal of the work. Their unobtrusive design ensures that once the work is complete, the nails remain hidden, allowing the beauty of the wood and craftsmanship to shine through. This aspect is particularly valued in upscale residential projects where every detail matters.

The evolution of finishing nails over the years has been marked by continuous innovation and improvement. Manufacturers are now offering nails that are specifically engineered for various applications, including those that require a more delicate touch and others that demand heavy-duty performance. This innovation is driven by customer feedback and the ongoing quest for better efficiency and precision in home improvement tools. Industry leaders such as Bob Vila and Family Handyman continue to provide insights into how modern finishing nails and nail gun technology are shaping the future of carpentry.

In summary, the comprehensive review of Finishing Nails presented here underscores their vital role in achieving professional-quality home improvement results. From their engineering design to the economic benefits they provide, finishing nails are a cornerstone of effective carpentry. With a market rich in options and continuous technological advancements, selecting the best finishing nails for your project has never been more critical. Armed with expert insights and data-backed research, you can now make an informed decision that will enhance both the functionality and appearance of your work.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

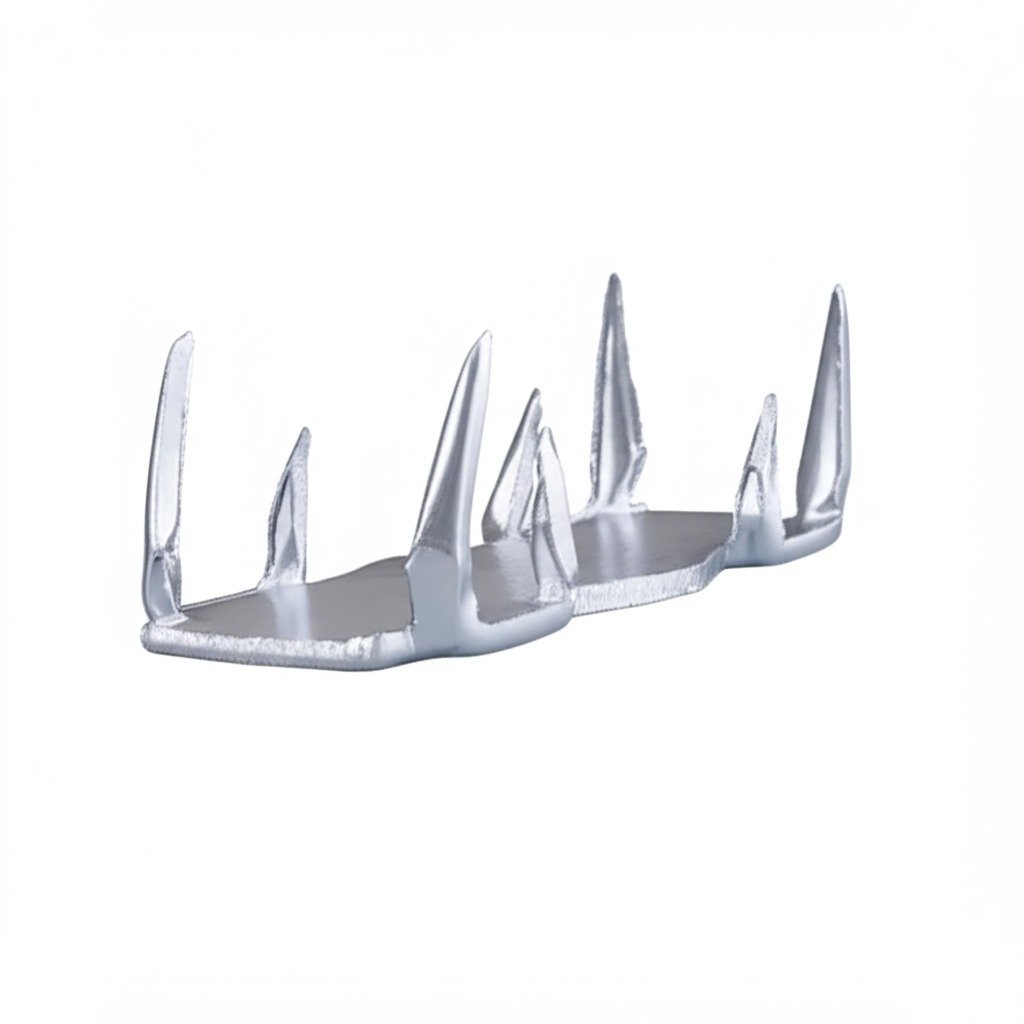

![W. H. HF167125 Hardened Flooring Nails [Misc.] [Misc.]](https://m.media-amazon.com/images/I/21uGuW6NHjL._SL500_.jpg)