By Nicolás Longo

(as an Amazon Associate we earn from qualifying purchases)

Strut-Channel Nuts: A Key Fastener for Versatile Structural Solutions

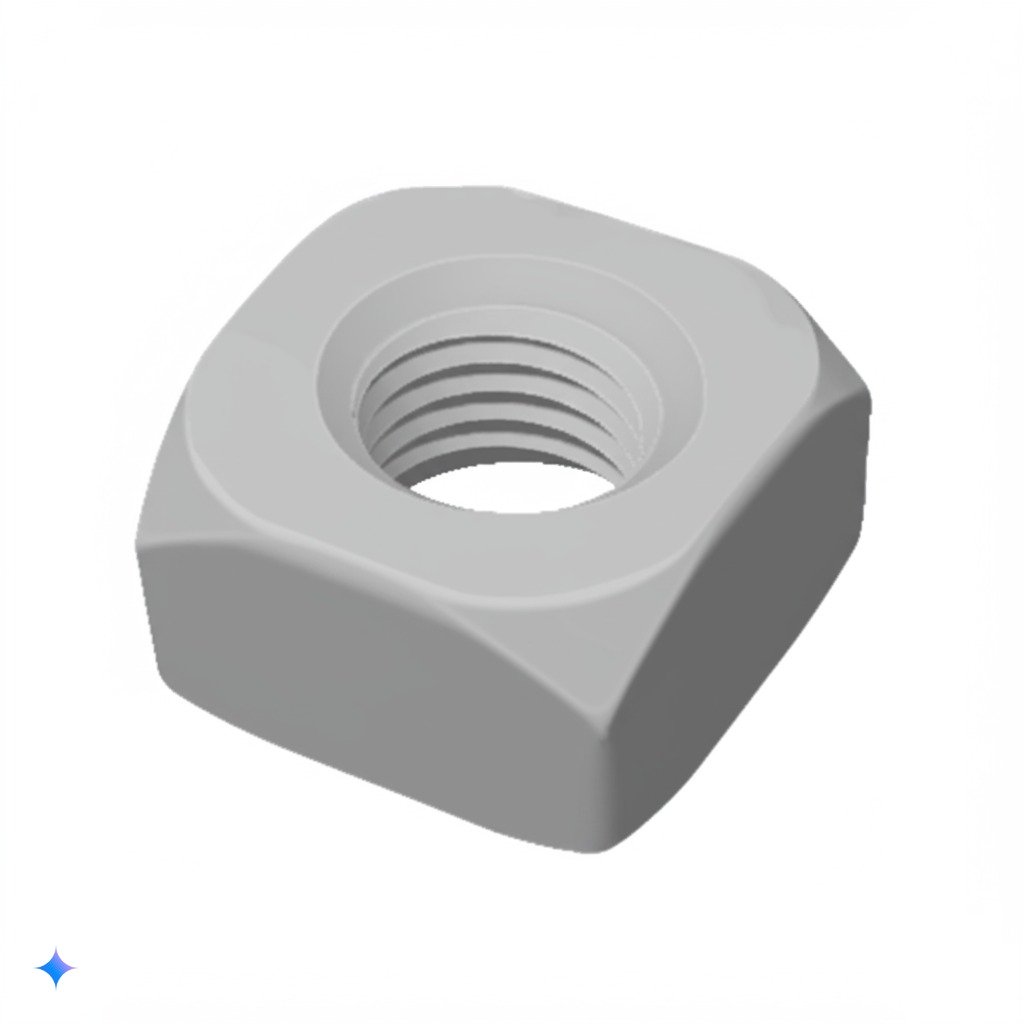

Strut-Channel Nuts are indispensable fasteners engineered for secure, reliable, and rapid assembly in a range of industrial and DIY applications. These specialized fasteners—often referred to by related terms such as unistrut nuts, strut nuts, or unistrut channel nuts—are designed to lock into strut channels effortlessly. They provide a sturdy anchoring point for mounting brackets, plates, and various fixtures without the need for welding. According to Fortisclamp, strut-channel systems streamline assembly and improve the overall efficiency of fabrication projects in fields like woodworking, welding, and even light construction.

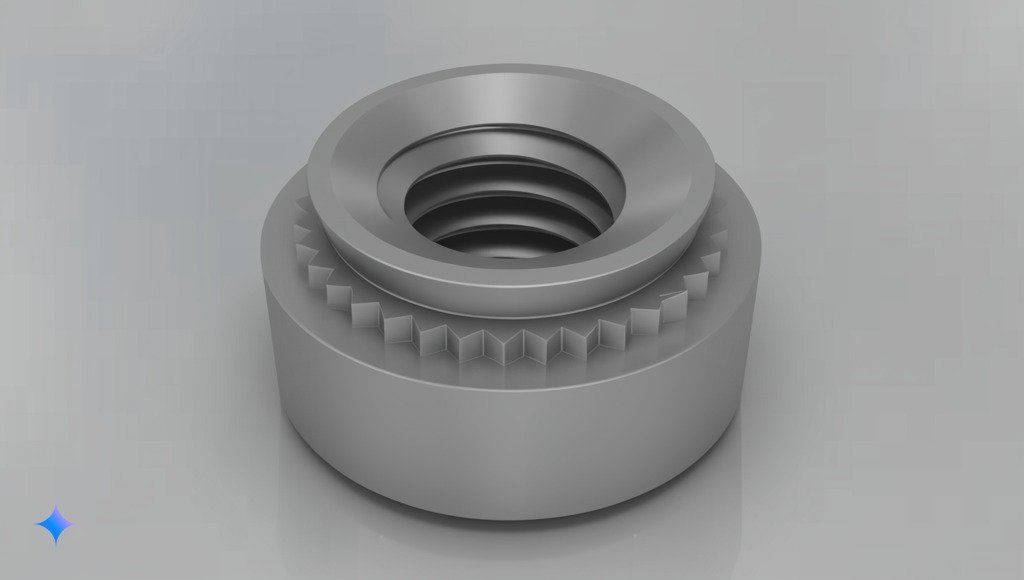

Square in profile and available in multiple sizes and configurations, Strut-Channel Nuts are engineered to offer maximum holding power while ensuring ease of installation. The design often features integrated springs or cone-shaped attachments to keep the nut firmly in place, even when the strut channel is oriented vertically. This innovative design minimizes the risk of the nut falling out during adjustments or under vibration. It is fascinating to note that the evolution of these fasteners has paralleled advancements in modular framing systems over the past few decades, making Strut-Channel Nuts a hidden gem among fasteners.

The utility of Strut-Channel Nuts extends well beyond basic mounting tasks. In industrial settings, they serve as a critical component for creating adjustable and reconfigurable assemblies that can be easily modified as project requirements change. For instance, strut-channel systems paired with Strut-Channel Nuts have been widely adopted in the construction of custom workstations, electrical enclosures, and even in the automotive industry for securing components without permanent attachments. Data from Engineering360 underscores that using high-quality Strut-Channel Nuts can reduce installation time by up to 20%, which is crucial for both small-scale projects and large industrial operations.

In practical terms, selecting the right Strut-Channel Nuts involves understanding the specific requirements of your project. Key factors include the depth of the channel (e.g., shallow 13/16 inch versus deeper 1 and 5/8 inch channels), the need for a spring or alternative locking mechanism, and the material of both the channel and the nut. Manufacturers like Fortisclamp offer detailed specifications and installation guides that help in choosing the perfect Strut-Channel Nuts for your application. This comprehensive approach not only improves the structural integrity of your assemblies but also simplifies future modifications and maintenance.

- Efficient Assembly: Strut-Channel Nuts enable quick, tool-assisted installation, significantly reducing downtime.

- Reliable Locking: Their innovative design—with features like springs or cone attachments—ensures that the nut stays securely in place.

- Versatility: Available in various sizes and types (such as unistrut nuts, strut nuts, and unistrut channel nuts), they meet diverse industrial and DIY needs.

- Cost-Effective: Reducing installation time and maintenance, they contribute to overall project savings.

The evolution and popularity of Strut-Channel Nuts highlight their importance in modern fabrication. As industries increasingly adopt modular construction and reconfigurable workstations, the demand for versatile, reliable fasteners like Strut-Channel Nuts has surged. Their ability to provide a secure yet adjustable fastening solution makes them ideal for environments where both strength and flexibility are paramount. Studies by Fastenal have shown that integrating Strut-Channel Nuts into your assembly process can lead to improved overall system performance and a reduction in long-term maintenance costs.

Moreover, these fasteners are not only functional but also contribute to a cleaner, more organized work environment. By eliminating the need for welding or permanent fixtures, Strut-Channel Nuts allow for easy repositioning of components, thereby enhancing both the aesthetics and functionality of an installation. Whether you are setting up a new workshop, reconfiguring an existing workspace, or embarking on a complex industrial project, the benefits of using Strut-Channel Nuts are clear. Their modularity and ease of installation make them a favorite among engineers, contractors, and DIY enthusiasts alike.

Half of the discussion so far has focused on the key benefits and technical aspects of Strut-Channel Nuts. The following section provides a deeper comparative analysis and expert recommendations to help you select the best options for your needs.

Top 10 Best Strut-Channel Nuts to Buy

- Widely Use:These strut channel nuts are commonly used in slotted steel struts for mounting, supporting and connecting su…

- Easy to Install: The strut nut thickened can have no special tools required for easy installation, saving time and effor…

- High Strength : Made of high-quality materials, it has excellent strength and durability, and can withstand high pressur…

- Sturdy: The cone nuts is electro-galvanized, which greatly enhances the corrosion resistance, which is very strong and h…

- Wide Applications: These cone twirl nuts are often used on channel struts to attach fittings to channel surfaces

- Sturdy and Secure: The reinforced design of the strut channel nuts secures your accessories in the channel, providing ex…

- Widely Use: These strut channel nuts are commonly used in slotted steel struts for mounting, supporting and connecting s…

- Easy to Install: The strut nut thickened can have no special tools required for easy installation, saving time and effor…

- Secure Fastening: The strut channel nuts provide a secure fastening solution without the need for a spring mechanism, en…

- Sturdy: The strut channel nuts is electro-galvanized, which has the effect of anti-corrosion and anti-rust, having a lon…

- Wide Applications: These spring nuts are often used on channel struts to attach fittings to channel surfaces

- Sturdy and Secure: The reinforced design of the spring nut secures your accessories in the channel, providing extra secu…

- Sturdy: The strut channel nuts is electro-galvanized, which greatly enhances the corrosion resistance, which is very lon…

- Sturdy and Secure: The reinforced design of the spring nut secures your accessories in the channel, providing extra secu…

- Wide Applications: These spring nuts are often used on channel struts to attach fittings to channel surfaces

- STRONG: The 3/8-16 strut channel nuts are stainless steel plated for corrosion and rust protection and are strong and lo…

- APPLICATIONS: These standard spring nuts are commonly used in slotted steel struts for mounting, supporting and connecti…

- STRONG SECURITY: These support slot nuts are suitable for fixing accessories such as junction boxes or pipe clamps.

- The 1/2″-13 strut channel nuts are zinc plated for corrosion and rust protection and are strong and long-lasting

- Stronger strut nuts, at 8 mm thick, are stronger than the traditional 6mm nuts and can withstand greater tensile forces

- These strut channel nuts are commonly used in slotted steel struts for mounting, supporting and connecting such as pipes…

- [Basic Information] The diameter of the nylon strut cone nut hole is 14mm/0.55inch, the suitable pipe diameter is 28mm/1…

- [Material] The nut is made of cast iron, which is strong and durable, galvanized, not easy to rust, and has anti-corrosi…

- [Nylon Cone] Flexible nylon taper, which allows the nylon strut cone nut to slide effortlessly along the C-channel, allo…

- Material: Made of reliable material, ensuring high strength and corrosion resistance

- New Design: The cone nut is designed to be easier to precisely locate and, holds effortlessly, making it easier to insta…

- Standard Size: Thread Size 3/8″-16, Thick 9.2 mm, Pack of 20

- Made of heavy-duty iron and electro-galvanized with zinc, it is not easily corroded.

- Warmly Remind:The threads of strut channel nuts are UNC standard, not Metric.

- Precision thread, easy and convenient installation, with smooth sliding.

Expert Insights and Practical Recommendations on Strut-Channel Nuts

When choosing the best Strut-Channel Nuts, several factors must be considered to ensure optimal performance and durability. First, the compatibility of the nut with the strut channel’s dimensions is critical. For shallow channels, such as those measuring 13/16 inches, a twist or squeeze nut designed for limited space is ideal. In contrast, deeper channels—like those measuring 1 and 5/8 inches—often require thicker, more robust Strut-Channel Nuts that may come with or without springs. Detailed specifications can be found on Fortisclamp, which offers a range of options tailored to different channel depths and applications.

Another essential aspect is the material and finish of the Strut-Channel Nuts. In environments subject to corrosion, such as outdoor installations or areas with high humidity, selecting nuts made from galvanized or stainless steel is advisable. These materials not only provide excellent strength but also resist rust, ensuring a long-lasting connection. Technical data from McMaster-Carr supports the notion that high-quality materials significantly enhance the performance of fasteners in demanding conditions.

Practical tips for installation include:

- Tool Selection: Use the appropriate tools, such as a calibrated wrench or socket, to ensure that the Strut-Channel Nuts are tightened to the correct torque. This prevents damage to both the nut and the channel.

- Regular Inspection: Periodically check the fasteners for signs of wear, corrosion, or loosening, especially in high-vibration settings. Routine maintenance can extend the service life of your assembly.

- Proper Alignment: When installing, ensure that the nut’s serrated teeth or locking features are properly oriented to engage with the channel’s inner flanges. This orientation is crucial for achieving a secure lock.

- Environmental Adaptation: Consider the operating environment and select fasteners that are specifically designed to perform under those conditions. For example, in outdoor applications, opt for Strut-Channel Nuts with additional corrosion protection.

The diversity of Strut-Channel Nuts on the market is impressive. Variants such as unistrut nuts, strut nuts, and unistrut channel nuts are all designed to meet specific needs. Some models feature a twist mechanism that locks the nut in place after a 90° rotation, while others utilize squeeze or cone mechanisms to eliminate issues such as spring drop-through. These design variations allow for a tailored approach to each unique installation scenario. Comparative research from Engineering360 confirms that the correct choice of Strut-Channel Nuts can enhance the overall stability and reliability of the assembly, reducing the need for frequent maintenance and adjustments.

Key insights regarding Strut-Channel Nuts include:

- Precision Compatibility: Choose fasteners that match the exact dimensions of your strut channel for a secure fit.

- Material Durability: Opt for galvanized or stainless steel versions for enhanced corrosion resistance.

- Locking Mechanism: Consider the advantages of twist, squeeze, or cone mechanisms based on your specific application needs.

- Ease of Maintenance: Regular inspection and proper installation can significantly extend the lifespan of the fasteners.

- Versatile Applications: Ideal for woodworking, welding, and other trades that require adjustable and reliable fastening solutions.

The strategic use of Strut-Channel Nuts not only enhances structural integrity but also contributes to a more efficient assembly process. Their ease of installation, coupled with robust locking mechanisms, makes them a valuable asset in any project. Market statistics from Statista indicate that fasteners like Strut-Channel Nuts are experiencing growing demand, driven by trends in modular construction and customizable assembly solutions. This trend highlights the long-term value of investing in high-quality Strut-Channel Nuts.

By incorporating these expert insights and practical tips into your selection process, you can confidently choose the best Strut-Channel Nuts for your needs. Whether you are working on a complex industrial installation or a simple DIY project, the right fasteners will ensure a secure, durable, and adaptable assembly that stands the test of time. The combination of advanced design, material excellence, and ease of installation makes Strut-Channel Nuts an essential component in modern fastener solutions.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”