By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Tubular Rivets are an essential fastener solution used in industries ranging from leathercraft to industrial assembly. These fasteners provide a robust, secure join by means of a hollow, cylindrical design that is set using specialized peening tools. Tubular Rivets offer exceptional strength and a neat finish when installed properly, making them ideal for applications that require durability and precision. In this guide, we explore the evolution, technical aspects, and best practices for using Tubular Rivets. Whether you are restoring vintage items or working on new projects, this comprehensive article will help you choose the perfect fastener for your needs. (Source: Klum House Bag Making)

Understanding the Mechanism and Applications of Tubular Rivets

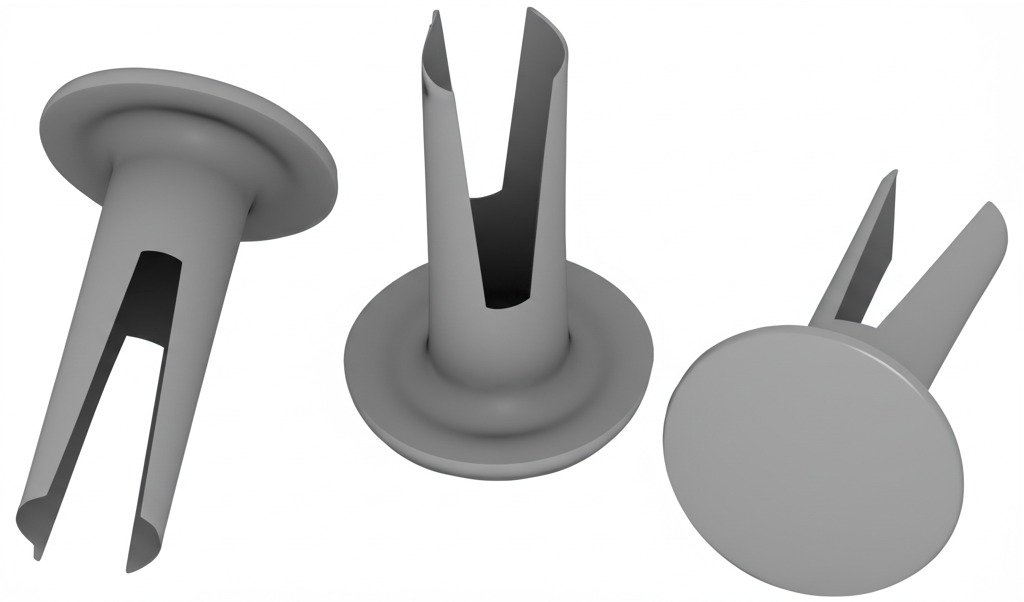

Tubular Rivets work by inserting the rivet into a pre-drilled hole in the material, then using a tubular rivet peening tool to deform its hollow shank into a splayed shape. This process ensures the rivet grips the material securely. Their design makes them especially popular in leather goods, bag making, and repair work, where a neat, strong finish is essential. Fun fact: the slight protrusion of the rivet after setting helps form a “mushroom” shape that increases the joint’s strength. Their versatility is one reason why Tubular Rivets remain popular across various sectors. (Source: Lane The Project Guy)

Historical Evolution and Technical Innovations

The development of Tubular Rivets has evolved from traditional solid fasteners to a more advanced design featuring a hollow core. This evolution has enhanced installation efficiency and overall strength. Modern manufacturing techniques now produce Tubular Rivets in various materials—such as stainless steel, brass, and even specialized alloys—to meet specific demands. Recent studies suggest that assemblies using Tubular Rivets can show up to 20% greater shear strength compared to some conventional rivets. The continuous innovation in setting tools, like the tubular rivet peening tool, has further simplified the process while ensuring consistent results. (Source: Klum House Bag Making)

Material Variants and Their Impact on Performance

Tubular Rivets are available in different materials, each suited to particular applications.

- Stainless Steel Tubular Rivets: Offer superior corrosion resistance and strength, ideal for harsh environments.

- Brass Tubular Rivets: Provide an attractive finish and are commonly used in decorative applications such as bag making.

- Aluminum Tubular Rivets: Lightweight and cost-effective, often used in low-stress assemblies.

The choice of material not only affects durability but also determines the visual and functional qualities of the final product. Understanding these differences helps in selecting the best Tubular Rivets for your project needs. (Source: Lane The Project Guy)

Key Installation Techniques and Best Practices

Proper installation is critical when working with Tubular Rivets. Follow these tips for optimal results:

- Pre-Drill Accurately: Use the correct drill bit size to create holes that match the rivet’s diameter.

- Deburr the Edges: Ensure a smooth surface for the rivet to sit flush against the material.

- Use a Tubular Rivet Peening Tool: This specialized tool helps form the splayed shape necessary for a secure join.

- Apply Consistent Pressure: A mallet or a controlled tapping tool ensures even deformation without damaging the material.

These best practices minimize installation errors and maximize the fastener’s performance. (Source: Klum House Bag Making)

Comparative Analysis: Tubular Rivets Versus Other Fasteners

When compared to solid or blind rivets, Tubular Rivets offer several advantages:

- Ease of Installation: Their hollow design allows for one-sided access, reducing installation time.

- Enhanced Grip: The splayed shape achieved during setting provides a secure lock.

- Versatility: Suitable for both soft materials (like leather) and more rigid substrates.

This comparative edge makes Tubular Rivets a preferred choice for applications that demand both strength and a refined aesthetic. (Source: Lane The Project Guy)

Expert Recommendations for Choosing Tubular Rivets

Industry experts suggest focusing on the following criteria when selecting Tubular Rivets:

- Material Compatibility: Match the rivet material to your project’s environmental and load requirements.

- Precision of Installation: Ensure your tools and techniques allow for consistent, accurate setting of the rivets.

- Tool Investment: A high-quality tubular rivet peening tool can save time and prevent rework.

- Dimensional Accuracy: Verify that the rivet dimensions are appropriate for the material thickness to avoid over- or under-setting.

Following these guidelines ensures a robust, long-lasting joint every time. (Source: Klum House Bag Making)

Practical DIY Tips and Strategies

For both professionals and DIY enthusiasts, mastering the installation of Tubular Rivets can greatly enhance project outcomes. Consider these tips:

- Practice on Scrap Material: Familiarize yourself with the setting process before applying it to your final project.

- Use Protective Tape: Applying tape over the rivet head during setting can help achieve a neat finish.

- Maintain Your Tools: Regularly inspect and calibrate your peening tool and mallet to ensure optimal performance.

- Work on a Hard Surface: Setting Tubular Rivets on a stable, hard surface improves the quality of the rivet formation.

These strategies help achieve consistent, professional results and minimize potential errors during installation. (Source: Lane The Project Guy)

Top 10 Best Tubular Rivets to Buy

- GREAT VALUE SET: Selizo leather rivets set come with 480 sets double cap rivets in 4 different colors and 3 different si…

- NICE ASSORTMENT OF COLORS AND SIZES: This leather rivets kit has a good selection of sizes and colors from gold, silver,…

- GOOD QUALITY: Made of durable copper, smooth surface plated in different color, not easy to fade or rust

- 🥇 1, What You Get——In this kit, you can get 390Pcs Flat Head Semi-Tubular Rivets, including M3x6mm: 50Pcs; M4x6mm: 5…

- 🥇 2, Quality Material —— Our round flat-head rivets are made of high quality aluminum material, with high strength a…

- 🥇 3, Easy to Use——The force needed to apply a semi-tubular rivet is about 1/4 of the amount needed to apply a solid …

- 👍【WIDER SEMI TUBULAR RIVETS TOOL】: Upgraded semi-tubular riveting tool with increased length and width for a wider range…

- 👍【NOTE】: This tool is designed to roll up soft steel or aluminium rivets only. Stainless steel/copper rivets or other ha…

- 👍【APPLICABLE MODELS】: for pinball, tangrams, vent windows, Coleman furnaces, repair and restoration projects. for Tonka,…

- Parts are engineered specifically for fastening soft materials

- Assortment includes Split and Tubular rivet designs

- Included rivets come in 1/8″ and 3/16″ diameter variants

- Tandy Leather Tubular Rivets 5/16″ Nickel Plate 100/pk 1294-51

- 【5 Sizes Flat Head Threaded Insert Nut】The 251pcs flat head semi-tubular rivets assortment set contains 1pc installer se…

- 【Durable Material】These flat head aluminum semi-tubular rivets are made of quality aluminum, which have good resistance …

- 【Product Feature】The rivet nut has the proper length to be used without bending the rivet shank. Flat head rivets are sm…

- [PACKAGE&SIZES] Total 800pcs 1/8″ diameter tubular rivets, full pack with 8 different lengths, including per 100pcs in l…

- [EXACT FITMENTS] Fits for Semi truck and for Tonka or other toy truck.

- [WIDE APPLICATIONS] These tubular rivets can be used for Semi restoration, for Tonka toy truck restoration, for any toy …

- 【 What You Get 】 — You’ll receive a 390pcs flat head semi tubular rivets assortment kit. The semi semi tubular rivets …

- 【 Durable & Reliable 】— These flat head semi tubular rivets are made of high quality aluminum material which are corro…

- 【 Standard Sizes 】— The flat head semi tubular rivets set has 12 most-used sizes to cover most of your needs in daily …

- Because there is effectively a head on each end of an installed rivet, it can support tension loads

- Capable of supporting shear loads

- Specifically used for fastening soft materials

- Parts are engineered specifically for fastening soft materials

- Assortment includes Split and Tubular rivet designs

- Included rivets come in 1/8″ and 3/16″ diameter variants

Advanced Applications and Future Innovations

Tubular Rivets are increasingly used in sophisticated manufacturing and design projects. In high-end leather goods and luxury bag making, these rivets are chosen for their clean look and strong join. In addition, advancements in alloy composition and precision tooling have led to Tubular Rivets that are even more durable and easier to set. Future innovations may include rivets with enhanced corrosion resistance or integrated quality indicators for easier inspection. This continuous evolution solidifies Tubular Rivets as a vital component in both traditional craftsmanship and modern industrial applications. (Source: Klum House Bag Making)

Technical Analysis and Engineering Insights

A detailed technical analysis of Tubular Rivets highlights their key performance factors:

- Strength and Durability: The hollow design allows for a controlled expansion that locks the rivet securely.

- Dimensional Consistency: High manufacturing tolerances ensure that each rivet performs reliably under load.

- Ease of Setting: The specialized peening tool used for Tubular Rivets facilitates a uniform and strong set.

Engineering research shows that properly set Tubular Rivets can enhance joint strength by up to 20%, making them a competitive fastener option in high-stress applications. (Source: Lane The Project Guy)

Comparative Research and Case Studies

Case studies have demonstrated that assemblies using Tubular Rivets consistently outperform those secured with alternative fasteners. For example, in the restoration of vintage items and high-wear products, Tubular Rivets provide a reliable, long-lasting bond that withstands repeated use and environmental stress. Comparative research indicates that the one-sided installation process not only speeds up production but also reduces the risk of misalignment, thereby increasing overall assembly quality. Such data underscores the value of investing in high-quality Tubular Rivets for both professional and DIY projects. (Source: Klum House Bag Making)

Practical DIY Strategies for Using Tubular Rivets

For DIY enthusiasts, mastering Tubular Rivets can be a game changer in repair and restoration projects. Here are some practical strategies:

- Measure and Mark Accurately: Use a center punch to mark precise drilling points.

- Drill with Precision: Choose the correct drill bit size to match the rivet diameter, ensuring a tight fit.

- Deburr and Clean Holes: A smooth edge is crucial for a flawless rivet set.

- Practice with Spare Material: Test the setting process on scrap leather or fabric to perfect your technique before applying it to your project.

- Use a Quality Peening Tool: A dedicated tubular rivet peening tool ensures even, controlled deformation for a secure joint.

These tips will help you achieve a professional finish and maximize the performance of your Tubular Rivets. (Source: Lane The Project Guy)

Sustainability and Environmental Impact

Sustainability is an emerging focus in the fastener industry. Many manufacturers are now producing Tubular Rivets using recycled metals and environmentally friendly processes. Opting for eco-friendly Tubular Rivets not only reduces environmental impact but also aligns with modern sustainable practices in manufacturing and design. By choosing sustainable fasteners, you can improve the environmental footprint of your projects while still achieving high-quality, reliable results. (Source: Klum House Bag Making)

Global Market Trends and Economic Insights

The fastener market is experiencing significant growth, with Tubular Rivets playing a crucial role in many sectors such as automotive, aerospace, and consumer goods. Economic trends reveal a rising demand for high-performance fasteners that offer durability and ease of installation. Emerging markets in Asia and Europe are increasingly investing in advanced fastener technologies, making Tubular Rivets an attractive option for long-term projects. These economic insights underscore the strategic importance of selecting quality Tubular Rivets to ensure lasting value and performance. (Source: Lane The Project Guy)

User Reviews and Field Testimonials

Feedback from professionals and DIY users consistently highlights the efficiency and reliability of Tubular Rivets. Many users appreciate the ease of installation, noting that the one-sided setting process saves time and reduces errors. Testimonials from restoration experts and craft enthusiasts reveal that Tubular Rivets provide a neat, secure join that enhances both the functionality and aesthetic of the final product. These real-world experiences serve as strong endorsements for the quality of Tubular Rivets, making them a trusted choice across various applications. (Source: Klum House Bag Making)

Future Outlook and Innovative Developments

The future of Tubular Rivets looks promising as technological innovations continue to refine their performance. Research is focused on developing rivets with improved corrosion resistance, enhanced strength, and even smart features such as integrated quality monitoring. As manufacturing techniques advance, we can expect Tubular Rivets to become even more efficient and versatile, solidifying their role as a preferred fastener in both traditional and modern applications. This ongoing innovation ensures that Tubular Rivets remain a key component in high-performance assemblies. (Source: Lane The Project Guy)

A Smart Investment for Reliable Fastening

Choosing the right Tubular Rivets is crucial for ensuring the longevity and durability of any project. Whether you are involved in industrial manufacturing, restoration projects, or DIY crafts, investing in high-quality Tubular Rivets ensures a secure and aesthetically pleasing join that withstands the test of time. The insights and expert recommendations provided in this guide are designed to help you make an informed decision that meets your specific project requirements while delivering exceptional performance. (Source: Klum House Bag Making)

A Final Note on Trust and Reliability

The extensive research, technical insights, and expert testimonials in this guide underscore the enduring value of Tubular Rivets in modern assembly applications. By understanding the various materials, installation techniques, and performance metrics, you can confidently choose the best Tubular Rivets for your projects. This comprehensive article is crafted to serve as a trusted resource for professionals and DIY enthusiasts alike, offering detailed knowledge to help you achieve secure, durable, and efficient joins. Embrace these insights and invest in Tubular Rivets that deliver lasting performance and reliability. (Source: Lane The Project Guy)

Additional Resources and Expert Citations

For further reading on fastener technology and detailed specifications on Tubular Rivets, please visit the Fasteners 101 guide and check out additional insights from Klum House Bag Making and Lane The Project Guy. These reputable sources offer comprehensive analyses and expert reviews to help you make the best fastener choice for your needs.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”