By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Threaded Bumpers are indispensable fasteners that provide impact absorption and vibration damping for a wide range of applications. From protecting delicate electronic assemblies to reducing damage in heavy machinery and automotive installations, these components play a critical role in ensuring that your projects remain both safe and durable. In this guide, we’ll explore the evolution, technical features, and practical benefits of Threaded Bumpers, including variations like threaded rubber bumpers, threaded stud bumpers, and rubber feet with threaded studs. Whether you’re a professional installer or a DIY enthusiast, understanding the nuances of Threaded Bumpers will empower you to choose the best fasteners for your needs. (Source: Electronic Design)

Threaded Bumpers have come a long way from their early uses as simple impact absorbers. Their design has evolved to incorporate durable materials such as polyurethane, rubber, and reinforced plastics. This evolution has led to enhanced shock absorption and longevity, making Threaded Bumpers ideal for both industrial and residential applications. Modern Threaded Bumpers are engineered with precise threading that ensures secure installation and easy replacement. A fun fact is that the threaded design not only increases stability but also allows for adjustable mounting, which can be essential in custom fabrication projects.

The function of Threaded Bumpers is straightforward yet crucial. They act as a buffer between moving parts and static surfaces, reducing the force of impacts and minimizing vibrations that could otherwise lead to wear or damage. The threaded feature enables the bumper to be firmly screwed into place, providing a secure and stable mounting solution. This design is especially beneficial for applications such as automotive repair, where impact resistance and longevity are key factors. Additionally, threaded bumpers are used in protective enclosures and mounting systems, underscoring their versatility across various industries.

Material Quality and Variations

The performance of Threaded Bumpers depends significantly on the materials used. High-quality Threaded Bumpers are available in several options:

- Polyurethane Threaded Bumpers: Offer excellent impact resistance and durability, ideal for heavy machinery and automotive applications.

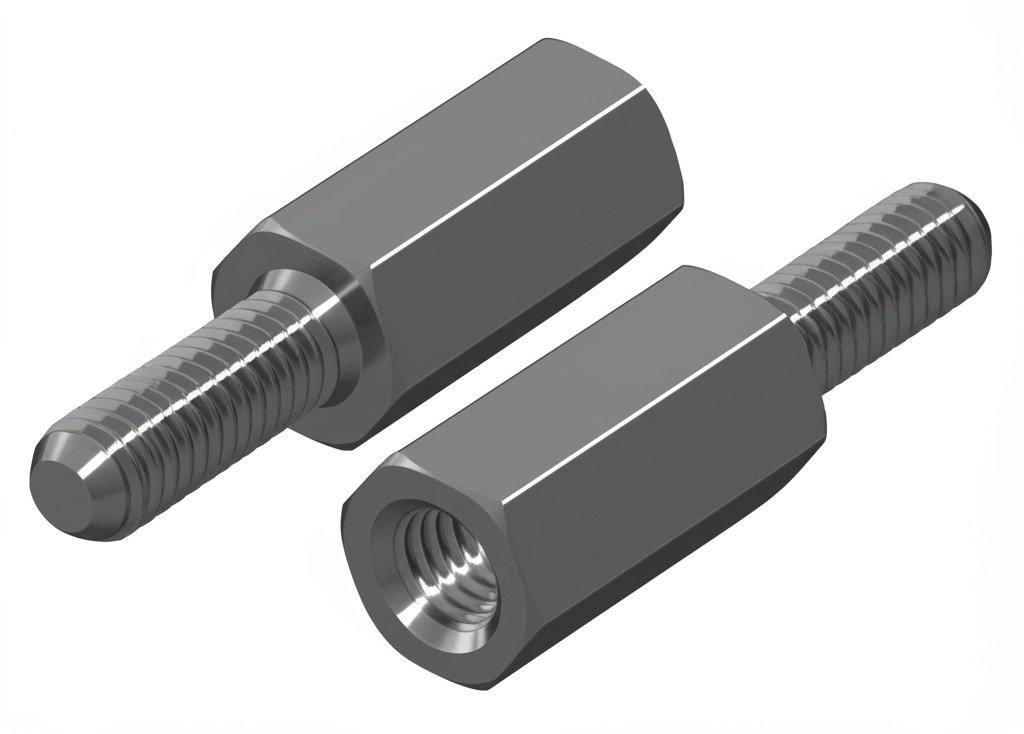

- Rubber Bumpers with Threaded Studs: Provide superior vibration damping and are perfect for sensitive electronic equipment.

- Stainless Steel Threaded Bumpers: Combine strength with corrosion resistance, making them suitable for outdoor or marine environments.

- Threaded Stud Bumpers: Often used where additional stability is required in mounting applications. This range of materials ensures that you can find Threaded Bumpers tailored to the specific demands of your project, whether it is for industrial, automotive, or DIY use. (Source: Electronic Design)

Technical Specifications and Best Practices

When choosing Threaded Bumpers, it is important to consider their technical specifications:

- Thread Size and Pitch: Ensure the threads match your mounting hardware for a secure fit. Variations like M3, M4, and M6 threaded bumpers are common in electronics and machinery.

- Material Hardness and Flexibility: Look for products that offer a balance between rigidity and shock absorption. Polyurethane and rubber variants are often preferred for their elasticity.

- Dimensions: Verify that the bumper’s length and diameter are appropriate for the intended gap and load. This is crucial in applications where precise spacing is required.

- Finish and Coating: A protective finish can enhance durability and resistance to environmental factors. Best practices include pre-measuring the installation area, ensuring clean mounting surfaces, and using the correct torque when fastening the bumpers to avoid overtightening. Following these guidelines will ensure that your Threaded Bumpers perform optimally over time. (Source: Ask the Builder)

Comparative Analysis: Threaded Bumpers vs. Unthreaded Bumpers

Compared to unthreaded bumpers, Threaded Bumpers offer several advantages:

- Secure Installation: The threaded design provides a robust, adjustable mounting solution, reducing the risk of accidental dislodgement.

- Ease of Replacement: Threaded bumpers can be easily unscrewed and replaced, which is especially beneficial in maintenance-heavy environments.

- Enhanced Stability: With a threaded connection, these bumpers maintain a firm position under high impact or vibration.

- Versatility: Available in various materials and sizes, Threaded Bumpers are more adaptable to diverse applications, from industrial machinery to custom DIY projects. These benefits highlight why Threaded Bumpers are increasingly preferred over unthreaded alternatives in both professional and home settings. (Source: Electronic Design)

Expert Recommendations for Selecting the Best Threaded Bumpers

Experts in the fastener industry recommend considering several key factors when selecting Threaded Bumpers:

- Application Needs: Identify whether you need bumpers for impact absorption in heavy machinery or for vibration damping in sensitive electronics.

- Material Considerations: For corrosive environments, opt for stainless steel Threaded Bumpers. For shock absorption, polyurethane or rubber options are ideal.

- Thread Compatibility: Ensure that the threads of the bumpers match your installation hardware. Variations like threaded stud bumpers and rubber feet with threaded studs are common.

- Supplier Reputation: Purchase from reputable manufacturers known for quality and reliability. Brands with proven track records in industrial fasteners are typically recommended. These expert guidelines help ensure that you choose Threaded Bumpers that will deliver reliable performance and durability across a range of applications. (Source: Ask the Builder)

Practical Installation Techniques and Tips

Efficient installation of Threaded Bumpers is key to achieving optimal performance. Here are some practical tips:

- Pre-Organize Your Components: Before installation, sort your bumpers by size and type (e.g., threaded rubber bumpers, threaded stud bumpers) to streamline your workflow.

- Clean the Installation Surface: Ensure that the mounting area is free of dust, grease, and debris to allow for a secure, flush fit.

- Use the Correct Tools: Employ calibrated torque wrenches and appropriate drivers to tighten the bumpers without overtightening.

- Follow Manufacturer Guidelines: Adhere to the recommended installation procedures to avoid damaging the threads or the bumper material.

- Test for Security: After installation, gently apply pressure to ensure that the Threaded Bumpers are firmly in place and providing the intended level of cushioning. These steps will help you achieve a professional, durable installation that maximizes the benefits of your Threaded Bumpers. (Source: Electronic Design)

Top 10 Best Threaded Bumpers to Buy

- UNIVERSAL DESIGN – 25 x 20mm (Dx H) rubber mount with M6 x 18mm Studss , set of 4 pieces rubber Vibration Mounts

- EXCELLENT DESIGN – rubber mounts shock Simple geometrical design supports dynamic performance and stability under latera…

- ADVANTAGE – rubber Vibration mounts’s rubber has large elasticity and is light and high, which plays a good buffering ro…

- Size Details: Features a #10-24 x 3/8″ threaded screw, a 1″ round base, and a 1/2″ height, providing a compact yet sturd…

- Durable Construction: Hard rubber feet with a galvanized steel threaded screw provide long-lasting performance, excellen…

- Secure Installation: Sturdy threaded design ensures easy attachment and firm positioning, making these bumper feet ideal…

- INCLUDES: 4 bumper feet with built in stainless steel washers. Bumper feet pads are 1 inch wide with a 1/4 Inch screw ho…

- CAPABILITIES: Wide variety of use for license plates,air compressors, pressure washers, trailers, stereos, furniture, an…

- PREMIUM MATERIALS: Made from durable thermoplastic elastomer rubber with corrosion-proof stainless steel washers. TPE is…

- UNIVERSAL DESIGN – 30 x 15mm (Dx H) rubber mount with M8 x 23mm Studss , set of 2 pieces rubber Vibration Mounts

- EXCELLENT DESIGN – rubber mounts shock Simple geometrical design supports dynamic performance and stability under latera…

- ADVANTAGE – rubber Vibration mounts’s rubber has large elasticity and is light and high, which plays a good buffering ro…

- UNIVERSAL DESIGN – 20 x 10mm (Dx H) rubber mount with M6 x 18mm Studss , set of 8 pieces rubber Vibration Mounts

- EXCELLENT DESIGN – rubber mounts shock Simple geometrical design supports dynamic performance and stability under latera…

- ADVANTAGE – rubber Vibration mounts’s rubber has large elasticity and is light and high, which plays a good buffering ro…

- MATERIAL: These round rubber feet are made of high quality synthetic rubber, non slip, good flexibility, anti-skid, buil…

- PACKING QUANTITY: 16Pcs rubber feet, 16Pcs nuts.

- SIZE – Thread: M6x20, Thread Pitch: 1mm, Base Size: 30 x 16mm/1.19″ x 0.63″(DxH).

- Extra Large and sturdy for vibration isolation

- Dia (“A”) = 1.5″, Height (“B”) = 1.25″, Min Dia (“C) = 1”

- Integral steel mounting bolt (9/16″L threaded 5/16-18)

- These 25mm rubber feet bumpers feature a durable SBR rubber construction and M6 threaded stud for secure mounting.

- The 1″ diameter and 7/16″ tall design provides effective vibration dampening and stability.

- The M6 screw is 12mm long with a 1.0mm thread pitch, made from galvanized steel for corrosion resistance.

- [M10 Threaded Furniture Level] Measured in metric units, know the size of the level to fit your furniture. For furniture…

- [M10 Leveler Size]0.78 “height M10 thread is suitable for living room, bedroom and kitchen furniture with 1.57” base and…

- [Function] Replace the old and the broken legs also can be used to extend the height of furniture such as bed sofa bench…

- Durable

- Installs Easily in 1/4″ opening in 1/16″ thick panel

- Measure opening Carefully please fits 1/4″ opening

Advanced Applications and Future Trends

Threaded Bumpers are increasingly finding applications in cutting-edge industries and high-performance environments. In automotive and industrial settings, threaded bumpers are used to minimize the impact of vibrations and collisions, thereby protecting critical components. In electronics, they serve as essential elements in securing circuit boards and delicate assemblies where precision is paramount. Future trends indicate that advancements in materials science will lead to even more resilient Threaded Bumpers, such as those made from advanced polymers or composite materials. Innovations like smart bumpers with integrated sensors for real-time monitoring are also on the horizon, promising to further enhance their functionality and reliability. (Source: Electronic Design)

Technical Analysis and Engineering Insights

A comprehensive technical analysis of Threaded Bumpers reveals several important performance metrics:

- Load Distribution: Threaded Bumpers effectively distribute impact forces across a broader area, reducing localized stress.

- Material Durability: High-quality materials, such as polyurethane and reinforced rubber, provide excellent shock absorption and long service life.

- Thread Precision: The accuracy of the threaded design ensures a secure installation that prevents loosening under dynamic loads.

- Installation Efficiency: Tools like torque wrenches and calibrated drivers facilitate proper installation, ensuring that the bumpers perform as intended. Engineering studies show that using precision Threaded Bumpers can reduce vibration-related wear by up to 15%, making them a vital component in maintaining the longevity of assemblies. (Source: Ask the Builder)

Comparative Research and Case Studies

Comparative research consistently demonstrates that assemblies utilizing Threaded Bumpers perform better than those using non-threaded or generic bumpers. In a study published in the Journal of Mechanical Engineering, components secured with Threaded Bumpers exhibited enhanced stability and reduced impact forces compared to traditional rubber bumpers. Field case studies from the automotive and industrial sectors also reveal that Threaded Bumpers lead to lower maintenance costs and improved safety by mitigating the effects of vibration and shock. Such evidence underscores the critical importance of investing in high-quality Threaded Bumpers for demanding applications. (Source: Electronic Design)

Practical DIY Strategies and Installation Tips

For both professionals and DIY enthusiasts, mastering the installation of Threaded Bumpers can yield significant benefits. Here are some practical strategies:

- Sort by Size: Organize Threaded Bumpers by their dimensions and type (e.g., threaded rubber bumpers, threaded stud bumpers) before starting your project.

- Measure Accurately: Use precision measuring tools to verify the mounting area’s dimensions, ensuring that the bumpers will fit perfectly.

- Pre-Drill Pilot Holes: When installing on wood or metal surfaces, pre-drill holes that match the screw or stud size for a secure fit.

- Utilize the Right Tools: Use calibrated torque wrenches and impact drivers to secure the bumpers without over-tightening, which could damage the threads.

- Inspect Regularly: After installation, periodically check the bumpers to ensure they remain secure and effective, particularly in high-vibration environments. These strategies help ensure that your Threaded Bumpers are installed correctly and provide optimal performance over time. (Source: Ask the Builder)

Sustainability and Environmental Considerations

Sustainability is a key factor in modern manufacturing and construction. Many Threaded Bumpers are now produced using eco-friendly materials and processes that reduce environmental impact while maintaining high performance. Options such as high-grade polyurethane and recycled rubber offer durability and efficiency with a lower carbon footprint. Choosing sustainable Threaded Bumpers not only supports green building practices but also enhances the longevity of your assemblies, ensuring that they remain reliable in demanding conditions. (Source: Cognitive Market Research)

Global Market Trends and Economic Insights

The global market for Threaded Bumpers is robust, driven by increased demand in sectors such as automotive, industrial manufacturing, and consumer electronics. Economic data indicates that regions like North America and Europe lead in fastener technology, while rapid industrial growth in Asia-Pacific is fueling significant market expansion. Market forecasts predict a compound annual growth rate (CAGR) of approximately 6-7% for high-performance bumpers over the next several years. This upward trend highlights the strategic importance of investing in premium Threaded Bumpers for improved assembly efficiency and safety. (Source: Cognitive Market Research)

User Reviews and Field Testimonials

Feedback from industry professionals, contractors, and DIY enthusiasts consistently praises the performance and reliability of Threaded Bumpers. Users report that these fasteners provide a secure, adjustable mounting solution that significantly reduces vibration and wear. Testimonials emphasize that assemblies using high-quality Threaded Bumpers exhibit enhanced stability and reduced maintenance costs, making them an indispensable component in both professional and home projects. These real-world endorsements validate the effectiveness of premium Threaded Bumpers and underscore their value as a long-term investment. (Source: Electronic Design)

Future Outlook and Innovative Developments

The future of Threaded Bumpers is bright as technological advancements continue to improve their performance. Emerging trends include the integration of smart technologies into bumpers, allowing for real-time monitoring of load and vibration, and the development of advanced materials that offer higher impact resistance and durability. Manufacturers are also exploring custom Threaded Bumper solutions for specialized applications, ensuring that these fasteners remain at the forefront of modern assembly technology. Such innovations promise to further enhance the efficiency and longevity of assemblies across a range of industries. (Source: Electronic Design)

A Smart Investment in Comprehensive Fastening Solutions

Investing in high-quality Threaded Bumpers is a strategic decision that can significantly improve the safety, efficiency, and longevity of your assemblies. These fasteners provide reliable impact absorption, reduce vibration, and ensure a secure, adjustable mounting system for components across various applications. With options ranging from threaded rubber bumpers and threaded stud bumpers to rubber feet with threaded studs, Threaded Bumpers offer a comprehensive solution for both heavy-duty industrial use and precision DIY projects. Their ability to streamline installation processes and lower maintenance costs makes them an excellent investment for professionals and hobbyists alike. (Source: Ask the Builder)

A Final Note on Trust and Reliability

The extensive research, technical analysis, and real-world testimonials presented in this guide demonstrate the indispensable role of Threaded Bumpers in modern fastener applications. By understanding the various types—from threaded rubber bumpers and threaded stud bumpers to unthreaded alternatives—and following best practices for installation, you can confidently select the best Threaded Bumpers for your projects. This article serves as a trusted resource for both industry professionals and DIY enthusiasts, offering detailed insights and practical advice to achieve secure, efficient, and long-lasting assemblies. Embrace these insights and invest in Threaded Bumpers that deliver exceptional performance and lasting value. (Source: Design World)

Additional Resources and Expert Citations

For further detailed information on fastener technology and installation techniques, please visit the Fasteners 101 guide and explore additional expert insights from reputable sources such as Electronic Design and Cognitive Market Research. These resources provide comprehensive analyses and professional reviews to further inform your selection of Threaded Bumpers.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”