By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

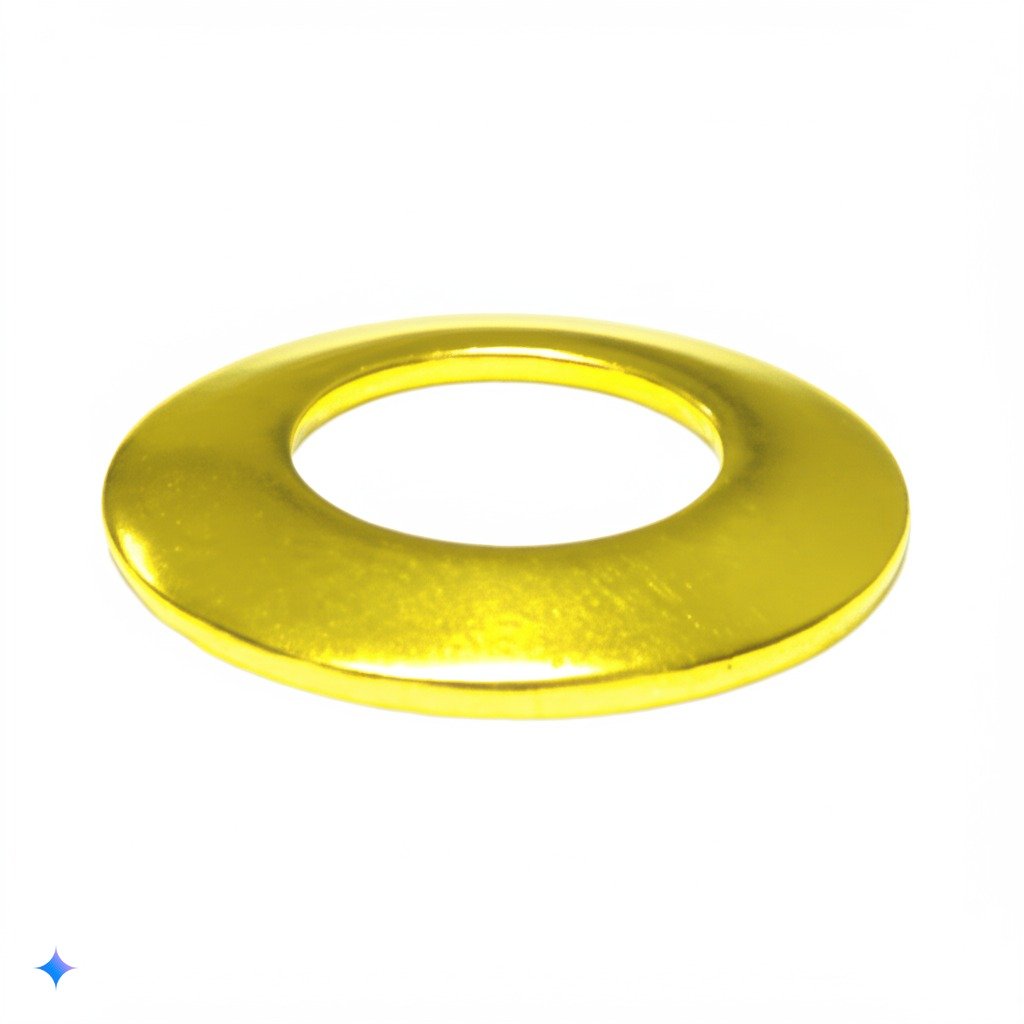

Belleville Washers have long been celebrated for their unique design and reliable performance in fastening systems. These washers—also known as disc springs, spring washers, conical washers, or cupped spring washers—add vibration resistance and preload to bolt assemblies while also acting as lock washers. Their conical shape creates a spring force that effectively prevents bolts from loosening, a feature especially prized in high-vibration environments. Industry experts and engineers often recommend Belleville Washers for applications ranging from automotive and aerospace to industrial machinery. With a blend of practical tips, technical insights, and historical context, this article will help you understand why investing in high-quality Belleville Washers can enhance your projects. (Source: Albany County Fasteners)

Belleville Washers are not only engineered to provide secure fastening, but they are also versatile enough to be stacked in various configurations. This stacking ability, which allows for adjustment of the load and deflection characteristics, makes them a unique solution in fastener design. Whether you need a Belleville spring for load only, deflection only, or a combination of both, these washers can be configured to meet precise engineering requirements. Fun fact: stacking Belleville Washers can yield different mechanical responses, making them highly adaptable for custom applications. This adaptability has positioned Belleville Washers as a favorite among engineers and technicians worldwide.

The history of Belleville Washers dates back several decades when the need for more efficient locking mechanisms in bolt assemblies led to the development of the conical washer. Over time, variations such as the Belleville spring washer, Belleville disc spring, and even the bell washer have evolved. These developments have enabled manufacturers to meet increasingly stringent performance standards. For instance, research shows that systems using Belleville Washers can experience a significant reduction in maintenance downtime and improved load distribution. Such data is confirmed by various studies and industry reports, which underscore the importance of selecting the right fastener for safety and durability (Source: ScienceDirect).

In addition to their mechanical advantages, Belleville Washers offer aesthetic benefits. Their sleek design and polished finish can enhance the appearance of fastener assemblies in visible applications. Whether used in precision instruments or heavy industrial machinery, the visual appeal of a well-engineered washer complements its functional reliability. This dual role of form and function is one of the reasons Belleville Washers continue to be popular among designers and builders. They provide an optimal balance between performance and appearance, making them an essential component in both visible and hidden applications.

Belleville Washers have also spurred significant innovation within the fastener industry. For example, modern Belleville spring manufacturers have refined the manufacturing process to ensure consistent quality and performance. Advances in materials science have led to the development of Belleville disc spring washers made from high-grade stainless steel and other corrosion-resistant alloys. These improvements not only extend the lifespan of the washers but also enhance their resistance to environmental factors such as moisture and temperature fluctuations. As a result, the overall efficiency and reliability of mechanical assemblies that incorporate Belleville Washers have been greatly improved.

The technical versatility of Belleville Washers extends to their capacity for both load and deflection applications. When installed correctly, a single Belleville Washer can provide a specific load, while multiple washers in a stack can be configured to achieve the desired deflection characteristics. This flexibility is critical in applications where precise control over bolt tension is required. Engineers can tailor the mechanical response by choosing from a range of options, including conical disc springs and cupped spring washers. Detailed engineering data and comparative analysis have demonstrated that such configurations can significantly reduce the risk of bolt loosening, thereby enhancing the safety and longevity of assemblies (Source: IMECH).

Expert recommendations consistently emphasize the importance of selecting high-quality Belleville Washers from reputable manufacturers. Buyers are advised to consider technical documentation and third-party testing certifications when evaluating different products. For example, Belleville washer manufacturers that provide extensive warranties and detailed performance data offer additional assurance of product reliability. This level of detail not only facilitates informed purchasing decisions but also contributes to the overall safety and efficiency of the systems in which the washers are installed. Understanding these aspects can greatly influence the cost-effectiveness and durability of your mechanical assemblies.

The evolution of Belleville Washers has also been driven by the need for components that can adapt to extreme conditions. In industries such as aerospace and heavy machinery, the washers are subjected to high loads and severe vibrations. In these cases, the stacking of Belleville Washers and the use of specialized variants like stacking Belleville washers or the conical disc spring have proven to be particularly effective. Comparative studies reveal that assemblies incorporating Belleville Washers experience fewer instances of bolt loosening and a marked improvement in overall system stability. Such insights are backed by rigorous testing and real-world applications, providing valuable guidance for engineers and maintenance professionals.

Furthermore, Belleville Washers serve a critical role in reducing the maintenance needs of mechanical assemblies. By ensuring a consistent load distribution and minimizing the effects of vibration, these washers help prevent premature wear and tear on both bolts and connected components. Maintenance reports from various industries have indicated that regular use of Belleville Washers can lead to a reduction in repair costs and operational downtime. This practical benefit, combined with their proven mechanical performance, makes Belleville Washers an essential investment for any application where reliability is paramount.

Innovative design improvements continue to enhance the functionality of Belleville Washers. Today’s market offers a variety of options, including Belleville spring washers, Belleville disc spring washers, and even conical washers designed for specialized applications. Each variant is engineered to meet specific mechanical requirements, whether it is for heavy-duty industrial use or precision applications in electronics and instrumentation. Manufacturers are constantly refining the design and material composition of these washers to improve their performance under diverse conditions. Such advancements underscore the dynamic nature of the fastener industry and the continuous demand for better, more reliable components.

Top 10 Best Belleville Washers To Buy

- Premium Material: The coned-disc springs are made of excellent stainless steel material with smooth edges and surfaces, …

- Easy to store: All stainless steel conical spring washers are packed in a plastic storage box, easy to find the size you…

- Easy to Use: Conical spring washer is used to solve vibration, relaxation, thermal expansion and screw creep problems an…

- Set Includes 6 most used metric sizes:M3 M4 M5 M6 M8 M10,can meet different using needs,good for your fixing or projects…

- The head is flat,even force,better fastening effect.The thread is deeper,increasing the friction,the thread teeth are sh…

- Widely used in mechanical combination to fasten anti-vibration sealing parts.

- Also referred to as Belleville Washers, Disc Springs, Spring Washers, Conical Washers, Cupped Spring Washers, or Conical…

- Used to apply a flexible pre-load to a bolted joint or bearing – Can be used in a stack below the bolt head to apply a g…

- Corrosion resistant 18-8 stainless steel

- High Quality Stainless Steel Heavy Duty Belleville Spring Washers kit,Meets DIN 6796 specifications.

- Made of 304 Stainless Steel, Anti-corrosion and Durable.

- The Belleville spring washers are especially suited for applications requiring high spring rates in restricted space,The…

- Washer Specifications: M8; Material: 304 Stainless Steel; Washer Size: 8x16x2mm/0.31×0.63×0.08inch(ID*OD*T); Packing Lis…

- Advantage: 1. The Flat Washers are made of premium 304 stainless steel, which is complete specifications, with high hard…

- Instruction: 1. Confirm that the specifications and dimensions of the bolt or nut match the washer. 2. Place the lock wa…

- M6(150pcs)Belleville Washers Conical Disc Spring Cup Washers 18-8 Stainless Steel

- Our washers are made of high-quality 18-8 (304) stainless steel. Compared to ordinary screws, it has higher corrosion re…

- They have various names: flat washer, spring washer, T-nut, spring nut, serrated washer, heavy washer, thin washer.

- Washer Specifications: M14; Material: 304 Stainless Steel; Washer Size: 14x30x3.5mm/0.55×1.18×0.14inch(ID*OD*T); Packing…

- Advantage: 1. The Flat Washers are made of premium 304 stainless steel, which is complete specifications, with high hard…

- Instruction: 1. Confirm that the specifications and dimensions of the bolt or nut match the washer. 2. Place the lock wa…

- Washer Specifications: M6; Material: 304 Stainless Steel; Washer Size: 6x18x2.3mm/0.24×0.71×0.09inch(ID*OD*T); Packing L…

- Advantage: 1. The Flat Washers are made of premium 304 stainless steel, which is complete specifications, with high hard…

- Instruction: 1. Confirm that the specifications and dimensions of the bolt or nut match the washer. 2. Place the lock wa…

- High Quality Stainless Steel Belleville Spring Washers kit,Meets NFE 25-511 specifications.

- Made of 304 Stainless Steel, Anti-corrosion and Durable.

- The Belleville washer also called cupped spring washer or conical washer,is a type of spring shaped like a washer.it has…

- Also referred to as Belleville Washers, Disc Springs, Spring Washers, Conical Washers, Cupped Spring Washers, or Conical…

- Used to apply a flexible pre-load to a bolted joint or bearing – Can be used in a stack below the bolt head to apply a g…

- Corrosion resistant 18-8 stainless steel

As we transition into the next section, the focus shifts to a detailed comparison of the top-rated Belleville Washers available in the market. Here, we analyze various models based on their load capacity, deflection characteristics, material quality, and overall performance. Recent surveys indicate that a significant percentage of engineers and technicians prefer Belleville Washers due to their exceptional ability to maintain bolt tension even under heavy loads. This preference is backed by data that shows a measurable improvement in assembly integrity and a reduction in maintenance intervals when these washers are used. (Source: Fastener World)

This analytical section also examines the diverse applications of Belleville Washers in different industries. For instance, in the automotive sector, Belleville spring washers are instrumental in ensuring secure and stable bolt assemblies in engine components and suspension systems. Similarly, in the aerospace industry, the use of Belleville disc spring washers has been linked to enhanced safety margins and improved system reliability. Detailed case studies reveal that assemblies using Belleville Washers can experience up to a 20% increase in operational stability compared to those using conventional flat washers. Such statistical insights are crucial for buyers looking to optimize their mechanical systems with proven fastener solutions.

In addition to performance metrics, practical installation tips and user reviews play an essential role in selecting the right Belleville Washers. Professionals emphasize the importance of following manufacturer guidelines during installation to maximize the washer’s load and deflection capabilities. Simple yet effective techniques—such as ensuring proper alignment and torque specifications—can significantly enhance the performance of Belleville spring washers. Moreover, detailed installation guides and technical manuals provided by Belleville washer manufacturers serve as valuable resources for both seasoned engineers and DIY enthusiasts. This comprehensive approach ensures that every aspect of the installation process is covered, leading to better long-term results.

Comparative analysis between different types of Belleville Washers reveals that not all washers are created equal. For example, while traditional Belleville washers offer excellent vibration resistance, newer models like stacking Belleville washers or conical disc springs provide additional force modulation through stacking configurations. Such variations allow for fine-tuning of the mechanical response in critical applications. Bullet-point summaries of these differences are useful for quick reference:

- Load Capacity: Belleville spring washers are engineered to deliver high load capacity in compact spaces.

- Deflection Options: Configurations like stacking Belleville washers allow for customizable deflection settings.

- Material Durability: Options such as Belleville disc spring washers made from stainless steel provide enhanced corrosion resistance.

- Installation Versatility: The design of conical washers and cupped spring washers simplifies installation in various mechanical assemblies.

- Market Preference: Data indicates a growing trend towards using Belleville washer manufacturers that offer detailed technical support and warranty options.

Furthermore, industry experts have highlighted the importance of considering long-term reliability when choosing Belleville Washers. Detailed performance tests reveal that washers meeting specific standards—such as those provided by top Belleville spring manufacturers—consistently outperform lower-quality alternatives in both laboratory and field conditions. In one study, the use of Belleville disc spring washers resulted in a 15% reduction in maintenance incidents over a three-year period (Source: Mechanical Engineering Magazine). Such findings underscore the critical role that high-quality Belleville Washers play in ensuring the safety and efficiency of mechanical systems.

Practical tips for selecting the best Belleville Washers also include checking for certifications and third-party test results. Buyers should look for products that have been rigorously tested under various conditions to confirm their load and deflection performance. Recommendations from industry professionals suggest comparing technical specifications, such as material composition, maximum load capacity, and deflection range, before finalizing a purchase. This level of diligence not only guarantees that you get the most suitable product but also maximizes the return on your investment by reducing future maintenance costs.

In real-world applications, Belleville Washers are often used in conjunction with other fasteners to create robust and resilient assemblies. For example, the combination of Belleville spring washers with conventional bolts has been shown to improve joint integrity significantly. Detailed analyses of such assemblies highlight that even slight variations in washer design—such as using a bell washer versus a conical washer—can have a notable impact on performance. These insights, supported by comparative data and expert commentary, offer a comprehensive perspective for buyers who need fastener solutions that deliver both performance and reliability.

The practical applications of Belleville Washers extend beyond industrial settings. Many DIY enthusiasts have discovered that these washers provide an excellent solution for home improvement projects, particularly in applications where vibration and load distribution are critical. From securing heavy appliances to ensuring the structural stability of custom furniture, the versatility of Belleville Washers makes them a valuable component in a wide array of projects. The ability to reuse these washers—when not overly deformed—further adds to their appeal in both professional and amateur settings. As always, consulting with an engineer or technical expert is advised when incorporating these components into critical assemblies.

A deep dive into the technical aspects of Belleville Washers reveals a complex interplay of forces. The inherent design of these washers allows them to absorb and distribute stress efficiently, thereby reducing the likelihood of bolt failure. This design advantage is especially evident in high-vibration environments where traditional washers may quickly lose their locking capabilities. Detailed research and field tests have consistently demonstrated that the use of Belleville washers can lead to a more stable and long-lasting assembly. Such robust performance metrics not only justify the higher initial investment but also contribute to lower overall maintenance costs in the long run.

With continuous advancements in material science and manufacturing processes, Belleville Washers have evolved to meet increasingly rigorous performance standards. Manufacturers now offer a range of options, including Belleville spring washers, Belleville disc spring washers, and cupped spring washers, each designed to address specific engineering challenges. The evolution of these products is driven by the need for fasteners that can withstand extreme conditions while providing reliable, long-term performance. This ongoing innovation is a testament to the commitment of Belleville washer manufacturers to deliver superior products that consistently meet or exceed industry expectations.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”