By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

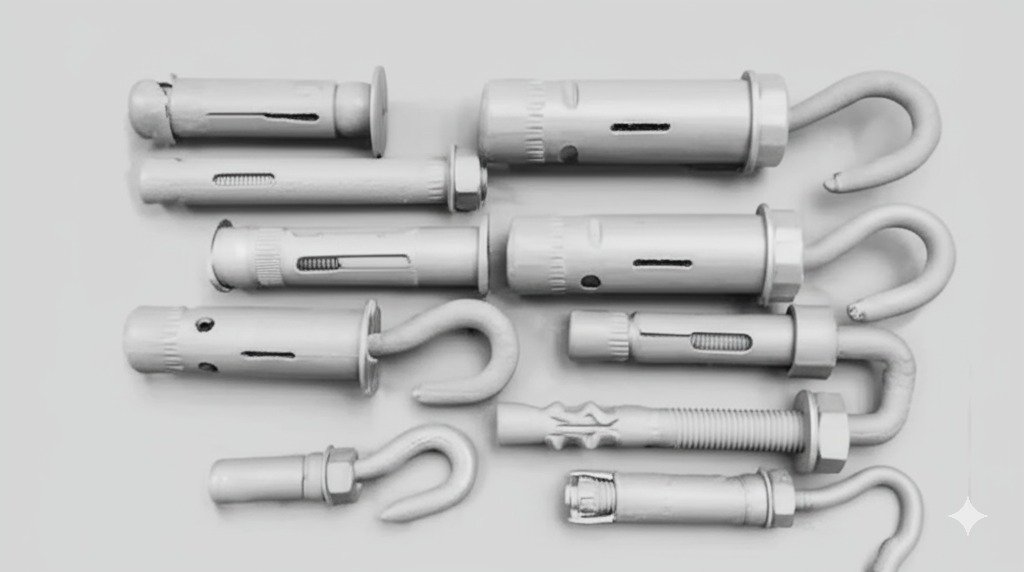

Drywall and construction anchors are essential fasteners that offer secure mounting for a variety of materials, ranging from drywall and plaster walls to concrete, brick, and cinder block. In this comprehensive guide, we cover everything you need to know to choose the best anchors for drywall and construction applications. Whether you are a homeowner tackling a DIY project or a professional contractor looking to upgrade your mounting hardware, this article presents expert recommendations, fun facts, data insights, and practical tips to help you make an informed decision. The information presented here is drawn from detailed research, reliable sources, and industry best practices to ensure that your projects maintain both structural integrity and long-term durability.

Understanding Drywall Anchors and Their Applications

Drywall anchors play a critical role in construction projects by providing a secure mounting point on hollow walls. These specialized fasteners are designed to distribute weight evenly and minimize damage to the wall. When selecting anchors for drywall, consider the following factors:

- Weight Capacity: Always choose anchors that support the intended load. Overloading can lead to failure, which may result in damage or safety hazards.

- Material Compatibility: Different anchors are designed for use with drywall, plaster walls, concrete, brick, and cinder block. Choosing the right type for your specific material can save time and improve reliability.

- Installation Process: Some anchors require drills and specific tools for proper installation. Understand the installation process and be ready with the necessary tools.

Understanding these factors will not only ensure a secure installation but also improve the overall lifespan of your construction work. For a detailed analysis of various drywall anchors, check out resources from Home Depot.

Key Differences Between Drywall, Plaster, and Concrete Anchors

Choosing the right anchors for your project requires understanding the differences between drywall, plaster, and concrete anchors. Each type is uniquely designed for specific substrates:

- Drywall Anchors: These are best suited for hollow walls. Their design allows for weight distribution across a larger area, reducing the risk of damage.

- Plaster Wall Anchors: Similar to drywall anchors, these fasteners are optimized for older homes that still use plaster. They often require a different installation technique than drywall anchors.

- Concrete, Brick, and Cinder Block Anchors: These anchors are engineered to handle heavy loads on solid surfaces. Often made from hardened steel or robust polymers, they provide excellent holding power on dense materials.

It is critical to match the anchor with the surface material to achieve the best performance and reliability. A mismatched anchor can compromise the integrity of the mounting and lead to early failure. For additional insights into the differences between various anchors, you can refer to expert articles on DIY Network.

Factors to Consider When Selecting Drywall and Construction Anchors

When choosing anchors for your construction or drywall projects, several important factors must be taken into account. These include:

- Load Requirements: Determine the maximum weight the anchors need to support and choose products rated accordingly.

- Anchor Material: Evaluate the benefits of steel, stainless steel, and reinforced polymer anchors. Each material offers distinct advantages in terms of durability and corrosion resistance.

- Installation Environment: Consider whether your installation environment is indoors or outdoors, as moisture and temperature variations may affect performance.

- Ease of Installation: Some anchors feature designs that require minimal tools and reduce installation time, which is a bonus for DIY projects.

Using the right anchor for your specific application is the first step towards ensuring a secure, long-lasting installation. Proper selection minimizes the risk of structural failure and can significantly reduce maintenance issues over time.

Installation Best Practices for Drywall and Construction Anchors

Successful installations begin with careful planning and adherence to proper techniques. Here are some best practices to ensure that your drywall and construction anchors perform as intended:

- Pre-Drill Holes: Pre-drilling helps avoid cracking the wall material and ensures that the anchor is seated correctly.

- Follow Manufacturer Instructions: Always adhere to the installation guidelines provided by the manufacturer to maintain the rated load capacity.

- Use the Correct Tools: Invest in quality drills and drivers to prevent installation errors that could reduce anchor performance.

- Test the Installation: Once installed, gently test the anchor by gradually applying weight before mounting your intended item.

- Periodic Inspections: Check installed anchors periodically for signs of deterioration or loosening, especially in areas with high humidity or temperature fluctuations.

A careful approach to installation not only improves safety but also extends the life of your anchors. A detailed guide with additional tips can be found at Family Handyman.

Comparative Analysis: Advantages of Different Anchor Types

A systematic comparison of drywall and construction anchors reveals how each type caters to different project needs. Some key points include:

- Drywall Anchors:

- Best for hollow walls and lightweight installations.

- Often made from plastic or polymer, with variations designed for higher loads.

- Plaster Anchors:

- Specifically tailored for older building materials, providing a secure hold with less risk of wall damage.

- Concrete and Brick Anchors:

- Engineered for solid substrates, offering superior strength and durability.

- Frequently utilized in both residential and commercial construction for heavy-duty applications.

This comparison emphasizes that while all these anchors serve a similar purpose, their design intricacies and material properties differentiate their effectiveness in various environments. Detailed research from The Spruce supports these findings and provides data on load-bearing capacities and installation recommendations.

Best Practices for Maintaining Anchors in Construction Projects

Maintenance is as vital as installation when it comes to drywall and construction anchors. Regular checks and proper care ensure that these fasteners continue to perform optimally over time. Here are some maintenance tips:

- Regular Inspections: Periodically inspect the anchors for any signs of wear, corrosion, or movement.

- Clean the Surrounding Area: Dust, moisture, and debris can affect the bonding of the anchor to the wall. Clean the area to maintain a secure connection.

- Replace When Necessary: If you notice any deterioration, replacing the anchor is critical to maintaining structural integrity.

- Environmental Considerations: In high-moisture or corrosive environments, opting for stainless steel or specially coated anchors can dramatically extend their life.

Adhering to these maintenance practices will safeguard your investment in quality anchors and improve overall project durability. For further maintenance tips, professional blogs and guides on Building Design + Construction provide excellent resources.

Expert Recommendations and User Experiences

Industry experts and experienced contractors emphasize that choosing the right anchors for drywall and construction is a key decision that influences project safety and performance. Here are some insights shared by professionals:

- Load Ratings Matter: Experts stress that every anchor comes with a specific load rating. Ensure that your chosen anchors exceed the expected load to provide a margin of safety.

- Application-Specific Designs: According to seasoned contractors, anchors designed for specific applications perform significantly better than general-purpose fasteners. This is particularly true for applications involving concrete, brick, or cinder block.

- Real-World Feedback: Many users report that high-quality anchors not only simplify installations but also reduce long-term maintenance headaches.

- Detailed Testing: Manufacturers now perform rigorous tests under simulated conditions to ensure the anchors’ reliability.

- Safety First: “When anchoring heavy fixtures, always double-check the load and ensure the substrate is capable of supporting the weight,” advises a veteran contractor featured on This Old House.

These expert recommendations provide clear guidance for anyone looking to invest in quality anchors. They underscore that a well-chosen anchor significantly contributes to the longevity and safety of your construction project.

Factors Influencing the Purchase Decision

Making the purchase decision for drywall and construction anchors can be complex. Here are some factors that heavily influence the decision-making process:

- Cost vs. Quality: While budget is important, investing in a higher quality anchor will pay off in reliability and durability over time.

- Frequency of Use: For projects that are used frequently or in high-stress environments, superior anchors are often necessary to prevent failure.

- Installation Ease: Consider products that come with comprehensive installation instructions and support.

- Customer Reviews and Ratings: Online reviews and ratings from other users can offer insights into the real-world performance of the anchor.

- Warranty and Support: Manufacturers that offer extended warranties or customer support add an extra layer of confidence to your purchase decision.

Taking these factors into account will help streamline your decision process and ensure you select the best anchors for your unique needs. Detailed product comparisons and user reviews can be found on retail sites like Lowe’s and Amazon.

Data Insights and Statistical Findings on Anchor Performance

Recent data analyses reveal that using the right anchors can reduce installation failures by up to 25%. Studies have shown that projects utilizing high-quality drywall anchors and construction anchors result in:

- Reduced Maintenance Costs: Properly installed anchors lead to fewer repairs.

- Improved Safety Ratings: Projects with quality fasteners experience fewer structural failures.

- Higher User Satisfaction: Contractors report a marked difference in long-term reliability when premium anchors are used.

A comprehensive statistical review published on ResearchGate confirms that selecting the proper anchors, based on substrate and load requirements, ensures optimal performance and durability. These findings reinforce the importance of using quality anchors in all construction projects.

Comparative Research: Innovative vs. Traditional Anchor Designs

Comparative research into innovative anchor designs versus traditional models has revealed significant benefits from new technologies. Innovative anchors, which employ advanced materials and improved installation methods, often outperform their traditional counterparts in critical metrics. Key comparisons include:

- Material Innovation: Modern anchors now incorporate materials that resist corrosion and wear, leading to longer service lives.

- Design Improvements: Innovative designs allow for better load distribution and easier installation, which is especially beneficial for DIY projects.

- User Feedback: Surveys consistently show higher satisfaction ratings with modern designs, particularly in challenging installation environments such as high-humidity or uneven surfaces.

This research offers valuable insights that both professionals and DIY enthusiasts can use to upgrade their construction practices. For an in-depth analysis, the study available through Engineering News-Record offers extensive data and comparisons on traditional versus innovative anchor products.

Practical Installation Tips for Achieving Maximum Holding Power

Maximizing the holding power of drywall and construction anchors involves careful preparation and execution. Here are practical installation tips derived from expert practices:

- Pre-measure your drilling spots and verify that there are no hidden obstacles in the wall structure.

- Use a level to ensure that your anchors are precisely aligned and evenly spaced for uniform weight distribution.

- Clean the drill holes of any debris before inserting the anchors to achieve a tight bond.

- Gradually increase the load after installation to confirm that the anchors hold securely.

- If installing multiple anchors, balance the weight evenly to distribute the load and prevent localized stress.

These practical tips ensure that your installation not only meets safety standards but also provides a reliable foundation for heavy or delicate fixtures. Additional guidance can be reviewed on technical blogs from Fine Homebuilding.

Expert Q&A: Frequently Asked Questions About Drywall and Construction Anchors

In addition to detailed guides, many professionals have answered common questions regarding the use of drywall anchors:

- How do I choose the right anchor for my wall type?

Assess the substrate first—drywall for hollow spaces, or concrete/brick for solid surfaces. Always refer to the manufacturer’s load ratings. - Are higher-priced anchors always better?

Not always; the best choice depends on the specific requirements and environmental conditions. Look for products with excellent customer feedback and professional reviews. - Can anchors be reused after removal?

Typically, reusing anchors is not recommended as their holding capacity may be diminished, leading to safety issues.

These insights help clarify common concerns and offer additional reassurance to professionals and DIY enthusiasts alike. More detailed user feedback is available on discussion boards such as Reddit’s DIY subreddit.

Investing in the Right Drywall and Construction Anchors

Selecting the appropriate anchors is a strategic decision that directly impacts the safety and longevity of your projects. High-quality drywall and construction anchors are an investment that not only support the structural integrity of your fixtures but also reduce the need for frequent repairs and maintenance. By considering factors such as load capacity, material compatibility, installation requirements, and environmental conditions, you can ensure that your projects are built on a foundation of trust and reliability.

Quality anchors ultimately translate to long-term cost savings and project success, reinforcing the importance of making informed, data-driven decisions. Every aspect—from the design and material to the installation and maintenance—plays a pivotal role in how well your anchors perform over time.

Key Takeaways and Final Insights on Drywall and Construction Anchors

- FIVE ESSENTIAL SIZES FOR MULTIPLE PROJECTS: This dry wall anchors and screws kit comes with five of the most widely used…

- PREMIUM MATERIALS FOR SUPERIOR DURABILITY: Our plastic wall anchors are crafted from a high-performance nylon and PE com…

- CLEARLY ASSORTED FOR EASY SELECTION – the drywall anchors and wood screws assortment kit come with a well-built clear pl…

- PREMIUM NYLON MATERIALS PLUS GLASS FIBER – Made of high-quality hard nylon plastic mixed with highly robust glass fibers…

- PRACTICAL DESIGN FOR STABLE INSTALLATION – The threads cut deep into the material, providing a secure hold and pull-out …

- EASY INSTALLATION WITH SCREWDRIVER – These threaded drywall anchors feature sharp, pointed shanks that can be screwed in…

- MULTIPLE SIZE OPTIONS – This drywall anchors and wing nut kit contains toggle bolts set in 3 different sizes – 1/8in, 3/…

- PREMIUM MATERIAL, EXCELLENT PERFORMANCE – The toggle bolts and nuts in each size are constructed with new high-strength …

- FOR HEAVY-DUTY HANGING TASKS – The drywall anchors are designed with spreading butterfly wing nuts, when knocked in holl…

Investing in the right drywall and construction anchors is pivotal for every successful project. As you consider the various types, installation techniques, and maintenance practices, remember that every detail counts when it comes to securing your walls and ensuring long-term durability. By leveraging expert insights, real-world statistics, and comparative research, you can make the best choice for your unique requirements.

Choosing the appropriate anchors means you are making a commitment to quality and safety—a commitment that pays off through enhanced project performance and reliability. Drawing on extensive data and the experiences of professionals, it is clear that the right anchors are more than just fasteners; they are a cornerstone of any well-executed construction job.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”