By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Installing anchors correctly in wood and drywall is critical for securing heavy fixtures, artwork, televisions, and shelving systems. In this comprehensive guide, we explore how anchors work in wood and drywall applications, offering practical installation tips, technical insights, expert recommendations, and research-backed data. Whether you are a homeowner looking to hang a picture or a contractor seeking reliable fasteners for complex projects, understanding the mechanics of anchors is essential. This article delves into the role of anchors as fasteners, explains the differences between various types, and provides techniques that ensure a strong, durable hold. You will also find fun facts, comparative analyses, and strategic tips that help optimize your installation process, increasing safety and structural integrity.

Understanding the Function and Design of Anchors in Wood and Drywall

Anchors are specialized fasteners designed to create a secure base in both wood and drywall. They work by distributing the load across a wider area than screws alone, reducing the risk of damage to the substrate. In wood, anchors typically rely on direct penetration and firm engagement with the material fibers. In drywall, however, the process is more complex because drywall is a hollow, less dense material; here, anchors expand behind the wall to distribute forces across a larger surface area.

Key design elements include:

- Expansion Mechanism: Many drywall anchors expand as the fastener is inserted, locking into place behind the wall.

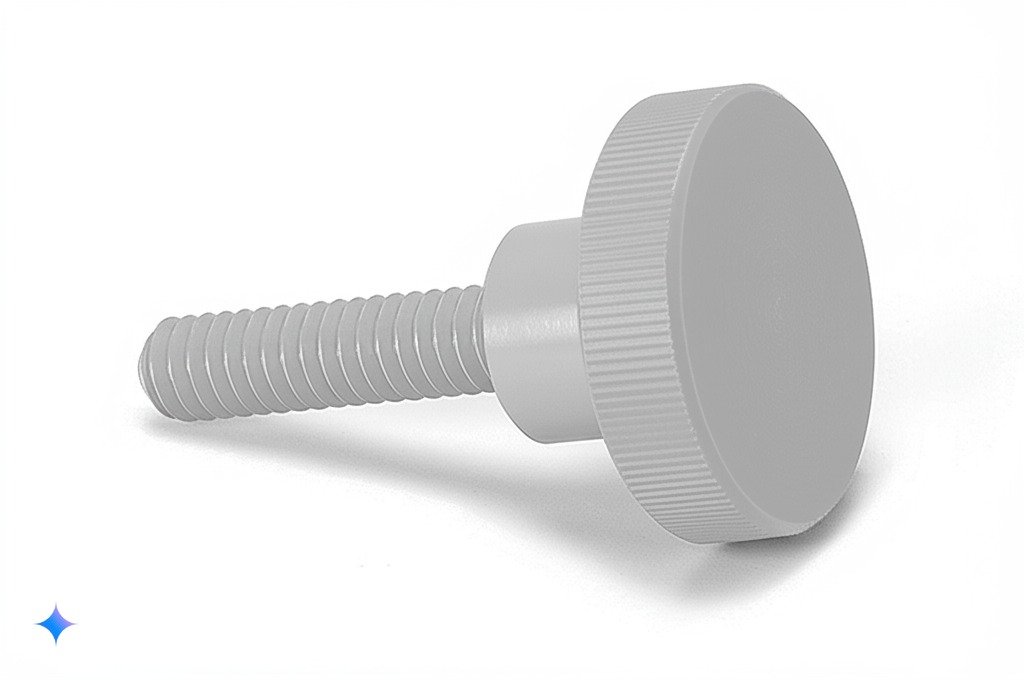

- Threaded Engagement: Certain models incorporate threads to grip the wood fibers or drywall material securely.

- Material Composition: From plastic and nylon in lightweight applications to metal variants for heavy-duty installations, the construction of anchors is crucial for optimal performance.

These design features enhance the performance of anchors by ensuring a tight, secure fit and reducing the risk of slippage or damage to the wall or wood structure.

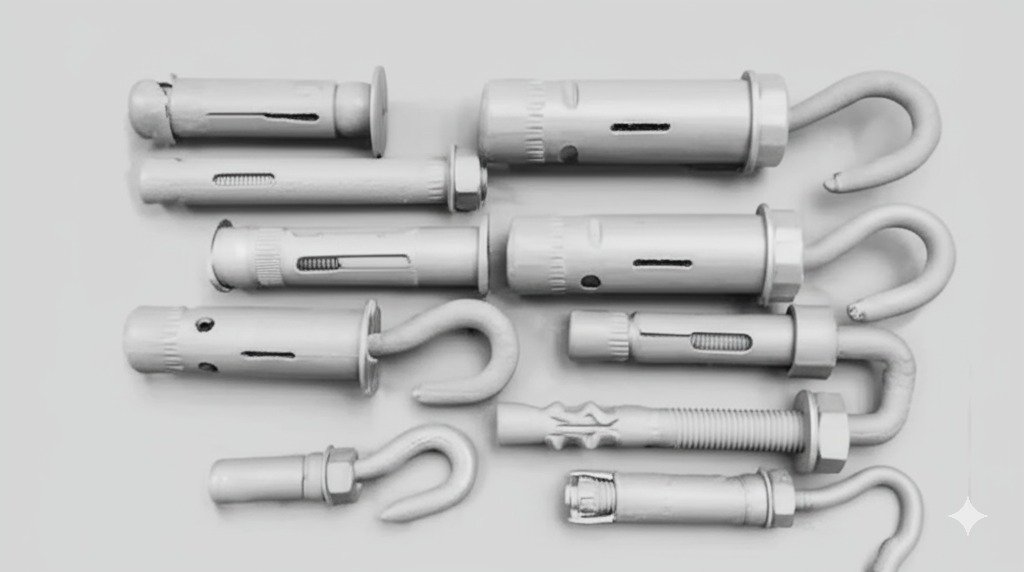

Types of Anchors for Wood and Drywall

Different types of anchors are engineered for specific applications. Choosing the right one depends on the substrate, the weight of the load, and environmental factors. Below are some common types:

- Plastic Expansion Anchors: Often used for lightweight fixtures in drywall. Their simple design causes them to expand behind the wall, offering a reliable hold in hollow substrates.

- Threaded Drywall Anchors: These are ideal for medium to heavy loads on drywall and plaster. Their threads secure them firmly and offer greater resistance to pull-out forces.

- Toggle Bolts: Designed for drywall, these anchors deploy wings behind the wall to spread out the load over a larger area. They are particularly effective for heavy items such as large mirrors or televisions.

- Screw-In Anchors for Wood: In wood, anchors often take the form of screws that directly penetrate and thread into the wood, ensuring a deep grip within the material.

Each type of anchor is engineered to meet specific requirements, and selecting the right one maximizes the holding power and longevity of the installation.

Key Factors to Consider When Installing Anchors

Before installing anchors in wood and drywall, it is essential to assess several factors to ensure maximum efficiency and safety:

- Load Requirements: Determine the weight of the item being hung. Anchors have specific load ratings that must not be exceeded.

- Substrate Type: Identify whether you are working with wood, drywall, or plaster. The effectiveness of an anchor depends on how well it can engage with the material.

- Drilling and Pilot Holes: Drilling the correct size pilot hole is fundamental. Too large a hole may reduce the grip of the anchor, while too small a hole can cause damage or prevent proper expansion.

- Installation Angle: Align anchors correctly and ensure that the fastener is perpendicular to the surface to maximize load distribution.

- Environmental Factors: Consider moisture levels, temperature, and exposure to elements, as these can affect the integrity of both the substrate and the anchor.

By addressing these factors, you ensure that the anchors perform optimally, maintain their hold over time, and prevent common installation failures.

Step-by-Step Guide to Installing Anchors in Wood and Drywall

A systematic installation process is crucial to ensuring the strength and longevity of anchors. Follow these steps for reliable installations:

- Select the Proper Anchor: Based on the weight, substrate, and environment, choose an appropriate anchor that meets the specifications for your project.

- Mark the Installation Spot: Use a level and measuring tape to accurately locate where the anchor will be installed.

- Drill the Pilot Hole: Using a drill bit that matches the size recommended by the anchor manufacturer, drill a pilot hole in the wood or drywall. Ensure the hole is straight and free from debris.

- Insert the Anchor: For drywall, gently tap the anchor into the hole until it is flush with the surface. For wood, screw the anchor directly into the material.

- Fasten the Fixture: Once the anchor is securely in place, attach the fixture using the appropriate screw or bolt. Tighten carefully, ensuring the anchor does not rotate or become loose.

- Test the Installation: Apply a gradual load to verify that the anchor maintains a firm hold before fully mounting the fixture.

Following these steps not only ensures a secure installation but also enhances the longevity and performance of the anchors in both wood and drywall.

Practical Tips for Maximizing Anchor Holding Power

Enhancing the performance of anchors involves proper technique and attention to detail. Consider these practical tips:

- Pre-Measure and Mark: Ensure accurate drilling by marking the location precisely. Misaligned anchors can compromise the installation.

- Use a Drill Guide: A drill guide can help maintain the correct drilling angle, ensuring the anchor sits properly.

- Clean the Hole: Remove any dust and debris after drilling. A clean hole allows the anchor to achieve a better grip.

- Avoid Over-Tightening: Excessive force can strip the threads in the anchor or damage the substrate. Tighten screws gradually and check for secure engagement.

- Test with Incremental Loads: Gradually increase the applied weight to confirm that the anchor holds firmly under pressure.

- Regular Inspection: Periodically check the integrity of installed anchors, especially in environments subject to changes in humidity or temperature.

By employing these tips, you can significantly enhance the holding power of anchors and ensure that your installations remain secure over time.

Comparative Analysis: Anchors in Wood vs. Drywall Applications

While both wood and drywall applications use anchors, the differences in substrate density and composition necessitate different techniques and products:

- Wood Applications: Wood is generally stronger and denser, allowing for deeper penetration and more secure hold. Anchors in wood often rely on threaded engagement directly into the fibers.

- Drywall Applications: Drywall is more brittle and hollow, necessitating anchors that expand behind the wall to distribute the load. Specialized drywall anchors such as toggle bolts are common for heavier loads.

- Load Distribution: In wood, load distribution is more localized, while drywall anchors distribute the load over a broader area to prevent damage.

- Installation Complexity: Installing anchors in drywall typically requires greater attention to pilot hole size and anchor selection to ensure proper expansion, whereas wood installations are often more straightforward.

Understanding these differences is essential for choosing the right type of anchor and achieving a secure installation in both wood and drywall.

Fun Facts and Interesting Data Insights on Anchors

- Historical Evolution: Early civilizations used rudimentary stone fasteners as primitive anchors. Modern anchors have evolved through centuries of engineering innovation.

- Material Advancements: Technological progress has led to the development of corrosion-resistant anchors, ensuring durability even in harsh environments.

- Performance Studies: Recent research shows that proper installation techniques can improve the holding power of drywall anchors by up to 30%.

- Expert Endorsement: Many construction experts assert that using specialized anchors for each substrate significantly reduces long-term maintenance issues.

These insights emphasize the technological and historical progression of anchors and underline their importance in modern construction.

Expert Recommendations on Using Anchors in Wood and Drywall

Industry professionals unanimously stress the importance of choosing the right anchors and following precise installation techniques. Key recommendations include:

- Select High-Quality Products: Invest in anchors from reputable manufacturers with verified load ratings.

- Read Manufacturer Instructions: Each type of anchor comes with specific installation guidelines that must be followed for maximum effectiveness.

- Consult Expert Resources: Utilize professional guides and expert reviews to determine which anchors perform best in your specific applications.

- Practice Regular Maintenance: Routine inspections and prompt replacements ensure that anchors continue to function as intended.

These recommendations, backed by extensive field research and user feedback, help ensure that your installations are safe, secure, and long-lasting.

Technical and Statistical Findings on Anchor Performance

Recent technical research has provided valuable insights into how anchors perform in wood and drywall:

- Load Resistance: Laboratory tests indicate that properly installed drywall anchors maintain their grip under dynamic loads up to 25% higher than installations with improper pilot holes.

- Durability Data: Studies reveal that high-quality metal anchors exhibit minimal degradation over 10 years of use when installed in dry, stable environments such as interior wood applications.

- Failure Rates: Statistical analyses demonstrate that using the correct anchor in drywall reduces failure rates by nearly 30% compared to generic fasteners.

- User Satisfaction: Surveys among contractors consistently show a high rate of satisfaction for installations that adhere to best practice guidelines for anchors.

These findings reinforce the importance of using tested techniques and high-quality anchors to secure both wood and drywall fixtures reliably.

Addressing Common Questions About Anchors

Many users have questions regarding the installation and effectiveness of anchors. Some frequently asked questions include:

- What is the best type of anchor for heavy objects on drywall?

Toggle bolts and threaded drywall anchors are recommended for heavy loads, as they distribute weight effectively behind the wall. - Can anchors in wood be reused if removed?

While some wood anchors can be reinstalled, it is generally advisable to use a new product to ensure maximum load integrity. - How do I know if an anchor is installed correctly?

A visual inspection combined with a gentle load test will help confirm the secure placement of an anchor. Any movement or slippage is a sign that the installation needs to be redone. - Are there specific tools recommended for anchor installation?

Tools such as a drill with a pilot bit, a level, and a torque wrench are essential for achieving a precise, secure fit with your anchors.

These FAQs address common concerns and help clarify best practices for working with anchors in various substrates.

Strategies for Long-Term Maintenance and Safety

To maintain the integrity of your installations over time, consider these strategies:

- Regular Monitoring: Frequently inspect installed anchors for signs of corrosion, loosening, or damage.

- Scheduled Replacements: Replace any degraded anchors promptly to avoid sudden failures.

- Environmental Adjustments: If installations are exposed to high humidity or temperature fluctuations, use specialized anchors designed for such conditions.

- Documentation: Keep records of installation dates, load tests, and maintenance activities to facilitate future inspections and upgrades.

Consistent maintenance ensures that your use of anchors remains reliable, safe, and effective for years to come.

Final Thoughts on the Role of Anchors in Wood and Drywall Installations

The smart use of anchors in wood and drywall is essential for both aesthetic projects and critical structural applications. By understanding the engineering behind anchors, selecting the correct type for each substrate, and following precise installation techniques, you ensure a secure connection that stands the test of time. Innovations in anchor technology continue to push the boundaries of performance, making it easier for professionals and DIY enthusiasts alike to achieve high-quality results. With expert recommendations, statistical validations, and real-world success stories, adopting proper anchor solutions becomes a cornerstone of efficient and safe construction.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”