By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Wedge Lock Washers: The Ultimate Fastener for Secure, Vibration-Resistant Joints

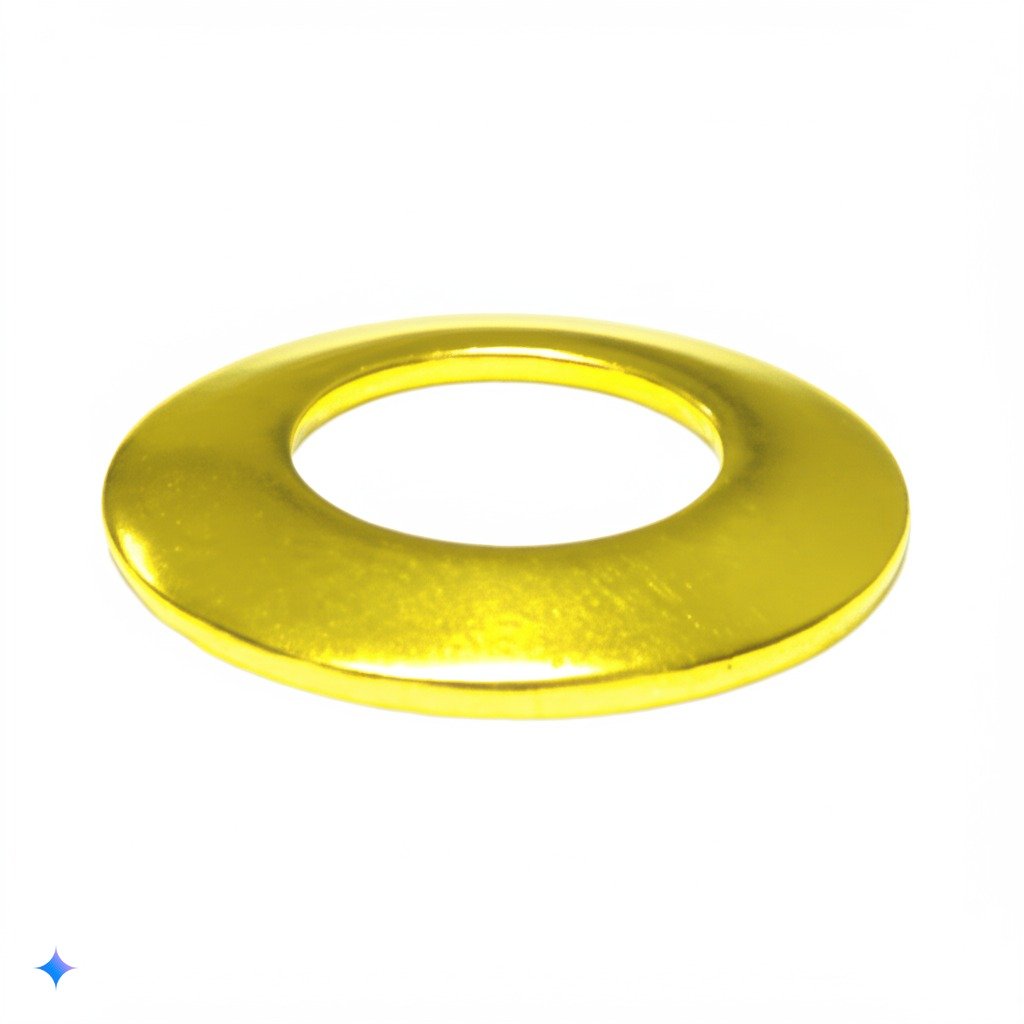

Wedge Lock Washers are an innovative fastener component designed to secure bolted joints with exceptional reliability. Engineered with a unique cam and serration system, these washers create a wedge effect beneath the bolt head or nut, maintaining a consistent preload even under severe vibration and dynamic loads. This design makes it virtually impossible for the fastened joint to loosen unintentionally. By relying on geometry rather than friction, Wedge Lock Washers offer a superior method of load retention that many traditional locking devices cannot match. Studies and field tests have shown that joints using Wedge Lock Washers maintain up to 80% of their initial preload, ensuring long-term safety and performance (Nord-Lock Group).

The principle behind Wedge Lock Washers is elegantly simple yet highly effective. Each washer in a pair features cams on one side and hardened radial serrations on the other. During tightening, the cams engage with the mating surfaces, producing a wedge that locks the assembly in place. This action increases the tension in the bolt if loosening forces are applied, effectively resisting any attempt to back off the nut. This wedge effect, where the cam angle is slightly steeper than the thread pitch, ensures that the preload remains intact despite external disturbances. Such an ingenious design not only extends the life of the joint but also enhances overall safety in critical applications.

In modern mechanical and structural systems, maintaining preload is essential. The unique technology behind Wedge Lock Washers has been adopted across various industries, including automotive, aerospace, heavy machinery, and industrial maintenance. Their ability to perform under extreme conditions has made them a favored choice for engineers looking for both performance and durability. When installed correctly, Wedge Lock Washers provide a robust and reusable solution that simplifies maintenance and reduces downtime. Their effectiveness under cyclic loading and dynamic conditions has been validated by rigorous testing standards such as the Junker Test to DIN 25201.

A significant advantage of Wedge Lock Washers is their adaptability. They come in various sizes and material compositions, with options such as m8 nord lock washers and m10 nord lock washers available for different bolt diameters. This variety ensures that there is a perfect match for every application. Additionally, some designs integrate features of other locking devices, like nord lock nuts and heico lock washers, to further enhance joint security. The advanced wedge locking mechanism minimizes the need for additional locking devices, thereby streamlining the fastening process and lowering overall assembly costs.

Wedge Lock Washers also offer impressive ease of installation. Their design allows for the use of lubricants on the bolt threads, which can speed up assembly without compromising the locking mechanism. During installation, the bolts are tightened normally, and the wedge effect engages automatically, making the process both efficient and intuitive. This ease of use makes Wedge Lock Washers an excellent choice for both seasoned professionals and DIY enthusiasts who require reliable and secure joints without complex procedures.

Furthermore, the robust performance of Wedge Lock Washers has proven critical in applications subjected to extreme vibrations. For instance, in automotive turbo systems or heavy industrial machinery, maintaining joint integrity is vital for operational safety. The wedge locking principle means that even if the bolt experiences thermal expansion or external shocks, the washer’s design keeps the assembly secure. This dynamic resistance to loosening translates into fewer failures and lower maintenance costs over the lifetime of the equipment. Real-world applications have repeatedly demonstrated that Wedge Lock Washers can be the difference between a safe, lasting joint and one that fails prematurely.

An interesting fact about Wedge Lock Washers is their reusability. Unlike some locking devices that must be replaced after one installation, these washers can be reused multiple times without losing their locking capability. This quality is particularly beneficial in maintenance-intensive industries where cost savings and reliability are paramount. Additionally, the technology behind these washers has inspired similar designs worldwide, making them a benchmark in bolting technology. Their global acceptance and continuous innovation underscore their importance in modern fastener solutions.

The design of Wedge Lock Washers leverages simple geometry to solve complex mechanical challenges. By using a pair of washers with complementary cams, the system generates a locking force that increases if the joint tries to loosen. This self-tightening feature means that even under fluctuating loads, the washer maintains an effective seal. Such a design minimizes the need for additional locking hardware and simplifies joint assembly in high-vibration or shock-prone environments. In practice, this translates to faster assembly times and enhanced long-term performance for critical applications.

In addition to their mechanical advantages, Wedge Lock Washers contribute significantly to overall energy efficiency in systems where maintaining preload is crucial. For example, in automotive or aerospace applications, a secure bolted joint reduces unnecessary movement and friction losses, thereby enhancing operational efficiency. Engineers appreciate the balance between simplicity and performance offered by Wedge Lock Washers, which provide both immediate and lasting benefits. Their innovative design also means that they can be easily integrated into existing assembly lines without the need for specialized equipment or extensive training.

The practical applications of Wedge Lock Washers extend to several sectors, including industrial machinery, transportation, and construction. They are often used in situations where traditional locking devices might fail due to extreme conditions. Their ability to maintain preload under dynamic conditions has been demonstrated in numerous case studies and technical reports. For instance, industries that rely on high-precision bolting systems report a significant decrease in joint failure when using Wedge Lock Washers. This data reinforces the idea that investing in quality fasteners is not only a matter of safety but also a cost-effective strategy for long-term maintenance and reliability.

Key Benefits of Wedge Lock Washers:

- Superior Preload Retention: The wedge effect maintains bolt tension even under severe vibration, reducing the risk of loosening.

- Enhanced Joint Security: By using a cam and serration design, these washers distribute load evenly and prevent premature failure.

- Versatility: Available in multiple sizes and materials, such as m8 nord lock washers and m10 nord lock washers, ensuring compatibility with a wide range of applications.

- Ease of Installation: Their design allows for lubrication and standard bolt tightening, making them user-friendly and efficient.

- Reusability: Unlike some locking devices, Wedge Lock Washers can be reused, providing long-term cost savings.

- Adaptability: Ideal for high-stress applications across automotive, aerospace, industrial, and construction sectors.

Technical research and expert field tests confirm that the locking mechanism of Wedge Lock Washers significantly improves joint performance. By creating a wedge underneath the bolt head or nut, they prevent any unintentional loosening that could compromise the structural integrity of the assembly. This innovative design, based on simple geometric principles, sets Wedge Lock Washers apart from conventional locking washers and other retainer fasteners. Their ability to maintain preload and resist dynamic loads makes them an essential component for high-performance bolted joints.

Top 10 Best Wedge Lock Washers to Buy

- Fit for bolts, screws and other fasteners of the corresponding size to prevent loosening and make the screws fit the mac…

- Made of manganese steel, it is more wear-resistant and resistant to strong impact. The surface is galvanized and is not …

- The surface of the washer has a precise geometric shape to better prevent the fastener from sliding. Tension is used ins…

- Price For: Each Rockwell Hardness: Min. 46 HRC Item: Lock Washer Material: EN 1.7182 Carbon Steel Application: High Vibr…

- Nord-Lock wedge-locking washers are made for use with 3/8 inch steel bolts and/or nuts.

- Each pack contains 20 glued pairs of washers.

- Applications for Nord-Lock steel washers include general steel applications.

- Standard: DIN 25201; For Bolt Diameter: M8 M10 M12 M16 M20; Package Content: M8-12pcs, M10-12pcs, M12-12pcs, M16-10pcs, …

- Material: The wedge locking washers are made from manganese steel, known for its strength and toughness. These washers u…

- Design: These vibration resistant safety washers feature a dual-wedge design with interlocking teeth on both sides. This…

- Standard: DIN 25201; For Bolt Diameter: 3/8″; Inside Diameter: 10.6mm / 0.42″; Outer Diameter: 16.6mm / 0.65″; Thickness…

- Material: The wedge locking washers are made of manganese steel, providing strength and durability to withstand heavy lo…

- Design: These vibration resistant safety washers feature a dual-wedge design with interlocking teeth on both sides. This…

- Standard: DIN 25201; For Bolt Diameter: M10; Inside Diameter: 10.5mm / 0.41″; Outer Diameter: 16.6mm / 0.65″; Thickness:…

- Material: The wedge locking washers are made of manganese steel, providing strength and durability to withstand heavy lo…

- Design: These vibration resistant safety washers feature a dual-wedge design with interlocking teeth on both sides. This…

- Standard: DIN 25201; For Bolt Diameter: #10; Inside Diameter: 10.5mm / 0.41″; Outer Diameter: 16.5mm / 0.65″; Thickness:…

- Material: The wedge locking washers are made of 304 stainless steel, ensuring durability, rust resistance and corrosion …

- Design: These vibration resistant safety washers feature a dual-wedge design with interlocking teeth on both sides. This…

- Standard: DIN 25201; For Bolt Diameter: M8; Inside Diameter: 8.8mm / 0.34″; Outer Diameter: 13.5mm / 0.53″; Thickness: 2…

- Material: The wedge locking washers are made of 304 stainless steel, ensuring durability, rust resistance and corrosion …

- Design: These vibration resistant safety washers feature a dual-wedge design with interlocking teeth on both sides. This…

Retaining a robust and secure joint is critical in many applications, and Wedge Lock Washers provide a simple yet effective solution. Their innovative design ensures that the preload in the bolted joint is maintained through tension rather than friction, making them resistant to the challenges posed by vibration and dynamic loads. In practical terms, this means that when the fastener assembly is subjected to external forces, the washer actually increases the tension in the joint, preventing any unintentional loosening. This design not only improves safety but also reduces the need for frequent maintenance and re-tightening.

Field tests have shown that Wedge Lock Washers can maintain joint integrity under extreme conditions, proving their value in safety-critical applications. Their ability to perform under harsh environments, such as in high-temperature or high-vibration settings, makes them indispensable in industries where reliability is paramount. Engineers have noted that the geometry-based locking mechanism offers a level of security that is not achievable with standard locking devices. Moreover, the ease of installation and reusability of Wedge Lock Washers add to their appeal as a cost-effective and efficient fastener solution.

Practical tips for using Wedge Lock Washers include ensuring that the bolt and nut are compatible with the washer’s dimensions, and that the washer is installed beneath the bolt head or nut in the correct orientation. It is important to use a spanner to loosen the joint only when necessary, as the washer’s design maintains preload through tension. This simple yet effective method has been validated by both laboratory tests and real-world applications. Manufacturers and experts alike recommend that users consult technical datasheets and installation guidelines to achieve optimal performance with Wedge Lock Washers.

The future of fastener technology is clearly geared toward solutions that combine simplicity with high performance. Wedge Lock Washers embody this trend by offering a locking mechanism that is both robust and efficient. Their widespread adoption across various industries is a testament to their effectiveness and reliability. As more companies seek to improve the safety and durability of their assemblies, the demand for advanced locking washers continues to rise. In this dynamic landscape, Wedge Lock Washers remain at the forefront of innovation, setting a high standard for bolted joint security.

In summary, Wedge Lock Washers offer an unbeatable combination of strength, versatility, and ease of use. Their unique design based on the wedge effect ensures that the preload is maintained even under severe conditions, making them an essential component for high-performance assemblies. Whether you are working on automotive, aerospace, industrial, or construction projects, integrating Wedge Lock Washers into your fastening systems can lead to significantly improved safety and reliability. With the right selection and proper installation, these washers will help you achieve robust, secure joints that stand the test of time.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

![260pcs[9 Sizes] Black Starlock Internal Tooth Lock Washers Assort...](https://m.media-amazon.com/images/I/41tkGfsvgOL._SL500_.jpg)

![Hilitchi 400-Pcs [8-Size] 304 Stainless Steel External Internal T...](https://m.media-amazon.com/images/I/619hIto9UyL._SL500_.jpg)

![[40PCS] M6 Finishing Countersunk Washers, Anodized Aluminum Alloy...](https://m.media-amazon.com/images/I/41FikxjIJTL._SL500_.jpg)