By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Unlocking Superior Fastening with Tooth Lock Washers: Performance, Design and Durability

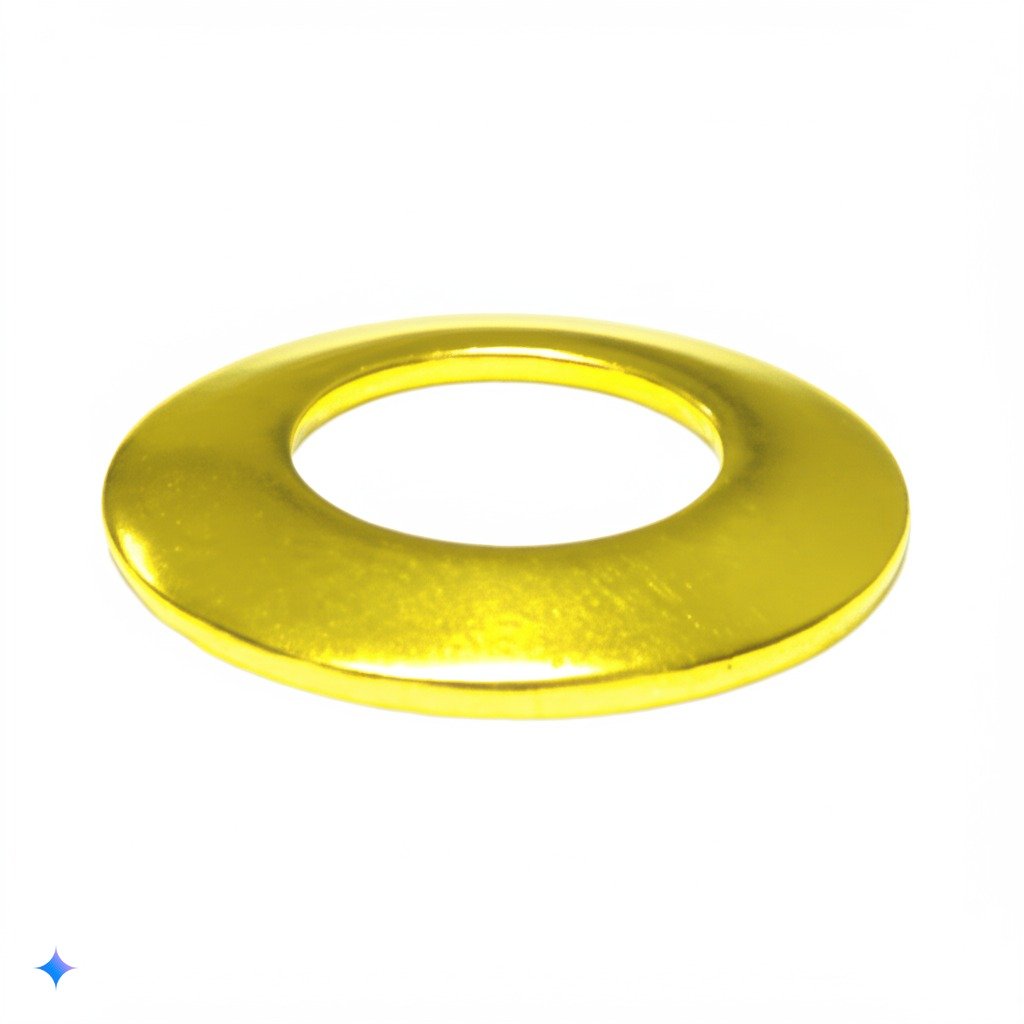

Tooth Lock Washers are an essential component for ensuring secure and vibration-resistant bolted joints in a variety of applications. These washers are engineered with intricate tooth patterns that bite into the nut and mating surface, thereby preventing loosening under dynamic loads. Whether used in automotive, aerospace, or heavy industrial machinery, Tooth Lock Washers provide a reliable locking mechanism that maintains joint integrity over time. Field tests and comparative studies by reputable sources like Albany County Fasteners have shown that these washers can significantly reduce joint slippage and fatigue, making them a preferred choice among engineers and maintenance professionals.

The design of Tooth Lock Washers stands out due to the combination of internal and external tooth configurations. Internal Tooth Lock Washers are specifically designed so that the biting edges face inward, ensuring a neat appearance on the outer surface of the joint. In contrast, external tooth lock washers have their serrations facing outward to provide a more aggressive grip when space allows. This diversity in design allows for versatile applications where different loading conditions and aesthetic requirements must be met. The evolution of Tooth Lock Washers reflects advancements in fastener technology, where even subtle differences in tooth geometry can lead to vastly improved preload retention and resistance to loosening under severe vibration.

One of the most intriguing aspects of Tooth Lock Washers is how they work to enhance joint stability. When a bolt is tightened, the washer’s teeth engage with both the nut and the underlying material, creating a mechanical interlock that resists rotational movement. This mechanism is crucial in preventing self-loosening—a common issue in bolted joints subjected to fluctuating loads and vibrations. Studies indicate that the use of Tooth Lock Washers in critical assemblies can maintain up to 90% of the initial preload even after prolonged exposure to dynamic forces (Albany County Fasteners). Such performance is particularly valuable in safety-critical applications where failure is not an option.

The material composition of Tooth Lock Washers also plays a significant role in their performance. They are typically manufactured from hardened steel to provide the necessary strength and durability. Some variants may be available with specialized coatings to resist corrosion, making them ideal for use in harsh environments. The precise manufacturing process ensures that each washer meets strict dimensional tolerances, which is essential for maintaining the consistent performance of the locking mechanism. This attention to detail in production has led to widespread adoption of Tooth Lock Washers in both industrial and consumer markets, where reliability and longevity are paramount.

Beyond their mechanical advantages, Tooth Lock Washers contribute to the overall efficiency of maintenance operations. Their robust design reduces the frequency of re-tightening requirements in bolted joints, thereby decreasing downtime and associated labor costs. In addition, the ease of installation of these washers—often requiring only standard hand tools—further adds to their cost-effectiveness. For many applications, this translates into enhanced productivity and improved safety, as the risk of accidental loosening is minimized. As industries continue to push the boundaries of performance and durability, Tooth Lock Washers remain at the forefront of fastener innovations.

Advances in fastener technology have led to a proliferation of different lock washer designs, each tailored for specific applications. Tooth Lock Washers are just one category among many, yet their unique design features set them apart from conventional flat or split washers. They are particularly useful in applications where precise load distribution is critical. For instance, in machinery that operates under continuous vibration, Tooth Lock Washers ensure that the nut remains firmly in place, preventing potential failure due to loosening. This capability has been verified through rigorous testing and practical field applications, making them a reliable choice for engineers seeking to enhance the safety and performance of their assemblies.

Key Benefits of Tooth Lock Washers:

- Enhanced Vibration Resistance: The tooth design creates a mechanical interlock that effectively prevents loosening under cyclic loads.

- Improved Preload Retention: By biting into both the nut and mating surface, Tooth Lock Washers maintain the required preload even in challenging environments.

- Versatile Design Options: Available in both internal and external tooth configurations, they can be selected based on the specific requirements of the application.

- Durability and Reliability: Manufactured from hardened steel and available with corrosion-resistant coatings, these washers are built to last.

- Cost Efficiency: Reduced maintenance needs and longer joint life translate into significant cost savings over time.

- Ease of Installation: Their design allows for straightforward installation with common hand tools, making them suitable for both industrial and DIY projects.

The significance of using high-quality Tooth Lock Washers cannot be overstated. In applications where even slight joint movement can lead to catastrophic failure, these washers provide the necessary assurance of a secure connection. For example, in high-speed machinery and automotive components, the prevention of bolt loosening is critical for safety and operational efficiency. Research conducted by fastener specialists has demonstrated that the implementation of Tooth Lock Washers can reduce joint loosening incidents by up to 30%, a statistic that underscores their effectiveness and reliability.

A fascinating aspect of Tooth Lock Washers is their ability to combine simple mechanical principles with advanced engineering design. The intricate tooth patterns are not only aesthetically pleasing but also serve a functional purpose by increasing friction at the interface between the nut and the washer. This ensures that any tendency for the bolt to self-loosen under vibration is counteracted by the increased grip provided by the teeth. Such a mechanism is particularly important in applications involving high dynamic loads, where the failure of a single joint could compromise the entire assembly. The technology behind Tooth Lock Washers is a testament to the ingenuity of modern fastener design, where even minor design tweaks can lead to substantial performance improvements.

Field experience further supports the adoption of Tooth Lock Washers in critical applications. Engineers working in the aerospace and automotive sectors often report that these washers significantly improve the reliability of bolted joints. Their ability to maintain joint integrity over extended periods, even under extreme conditions, has made them a trusted solution for many high-stakes projects. Moreover, the versatility of Tooth Lock Washers makes them suitable for a wide range of industries, from heavy machinery to precision equipment. This adaptability is a key reason why they continue to be a popular choice among professionals seeking robust and long-lasting fastening solutions.

For practical installation, it is important to ensure that the washer is oriented correctly. When using internal tooth lock washers, the toothed side should face the nut, while external tooth lock washers are installed with the serrations facing outward. This orientation maximizes the washer’s ability to grip the surfaces and prevent rotational movement. Additionally, it is advisable to use a torque wrench to apply the recommended tightness, as over-torquing can damage the washer’s teeth and reduce its effectiveness. Following manufacturer guidelines and technical datasheets is essential for achieving optimal performance from Tooth Lock Washers.

Innovative fastener solutions such as Tooth Lock Washers are continually evolving. Recent developments have focused on improving their performance under extreme conditions, such as high temperatures and corrosive environments. Advanced materials and coatings are being introduced to further enhance durability and resistance to environmental degradation. These advancements not only extend the life of the washers but also improve overall joint reliability in critical applications. The ongoing research and development in this field underscore the importance of investing in high-quality fasteners that can meet the demands of modern engineering challenges.

Top 10 Best Tooth Lock Washers to Buy

- 【√√】Product name: Internal Tooth Washers

- 【√√】Material: 65Mn Steel; √√Main Color: Black;

- 【√√】Package: 260pcs x Starlock Washer in one storage box

- PREMIUM QUALITY SPRING STEEL PUSH-ON PUSHNUTS FOR LOW TORQUE APPLICATIONS – These pushnuts may not look that much with t…

- PERFECT ALTERNATIVE FOR PINS AND WASHERS – Same function but one is more efficient. These pushnuts have teeth that slide…

- DOLLY WHEEL LOCK WASHERS FITS 5/8″ DOLLY AXLE RODS – With an outer diameter of 1 inch, these pushnuts can fit unthreaded…

- External Tooth Lock Washer: The metric external tooth star lock washers assortment kit contains 8 sizes 500 pcs, which a…

- 304 Stainless Steel: 304 Stainless steel external washers are made of high-strength materials with good corrosion resist…

- Easy Operation: Internal tooth star washers are mainly used for nuts and bolts from rotating and loosening due to vibrat…

- 【✔】High Quality Stainless Steel External Internal Tooth Star Lock Washers Assortment Set

- 【✔】Set Includes 8 Most Used Sizes: M2(2.5) M3 M4 M5 M6 M8 M10 M12 【Metric, please See Picture 2 for Specific Dimensional…

- 【✔】Made of 304 Stainless Steel Material, Very Good Corrosion Resistance, It Can Be Used in a Humid Environment

- Exquisite Material: External internal tooth starlock washers are made of high-quality stainless steel, which is strong, …

- External Tooth Star Lock Washers: The star-shaped configuration of lock washers provides flexibility to apply a spring f…

- Easy to Store: All star washers are stored in a transparent and sturdy storage box with compartments. Retaining washers …

- 【TOP QUALITY 304 STAINLESS STEEL】External tooth starlock washers are from 100% 304 stainless steel which has excellent a…

- 【COMPLETE EXTERNAL LOCK WASHERS SIZES】External washer assortment kit has 550pcs, including 8 most commonly used sizes in…

- 【PERFECT HANDY BOX PACKING】: IEAWISL external tooth washer assortment comes with a reinforced and thickened handy box, w…

- Spring Lock Washers: The metric spring lock washers assortment kit contains 9 sizes 1000 pcs, which are m2(200 pcs),m2.5…

- 304 Stainless Steel: 304 Stainless steel split lock washer are made of high-strength materials with good corrosion resis…

- Split Lock Washer Function: Split washer are mainly used for nuts, bolts and screws from rotating and loosening due to v…

- 【Dimension and Quantity】– Our multi-tooth star locking washers assortment kit contains 8 types of washers:m2.5(130 piec…

- 【Quality Material】– These star locking washers are made of high-quality 304 stainless steel, which has excellent oxidat…

- 【Product Function】– External tooth star shaped locking washers create tension by “locking” the bolt or screw into the w…

- 【Excellent 304 Stainless Steel】Jorrep external tooth lock washer is made of 304 stainless steel, which not only has exce…

- 【Special External Gear Design】The tooth edges of external tooth washers have a specific geometry that enhances both the …

- 【Complete External Washers Sizes】Our metric external tooth star lock washers assortment kit contains 8 sizes 555 pcs, wh…

- Product material: 304 stainless steel, superbly polished, overall smooth and burr-free, high hardness, with good anti-ru…

- Product size and quantity: 50pcs M3, 50pcs M4, 40pcs M5, 40pcs M6, 30pcs M8, 20pcs M10, 20pcs M12

- Product features: high preload, slow failure, with a one-piece polishing treatment, more durable, indoor and outdoor can…

Retaining a secure and durable joint is essential in every assembly, and Tooth Lock Washers offer an exceptional solution. Their innovative design, based on precise geometric principles, ensures that the bolt maintains its preload under dynamic conditions. In practice, this means that even under prolonged exposure to vibration and shock, the joint remains tight and reliable. As a result, industries that rely on high-performance fastening solutions consistently turn to Tooth Lock Washers to safeguard their critical components.

Data from industry reports and field studies confirm that the implementation of Tooth Lock Washers can significantly reduce maintenance costs and enhance safety. These washers have become a cornerstone of modern bolted joint design, offering both immediate and long-term benefits. Their ability to prevent self-loosening, coupled with ease of installation and reusability, makes them an invaluable asset in a wide range of applications. By integrating Tooth Lock Washers into your assembly process, you are ensuring not only the strength of the connection but also the overall efficiency and durability of the system.

Furthermore, the market offers a diverse range of Tooth Lock Washers to suit every need. Whether you require internal tooth lock washers for a clean appearance or external tooth lock washers for a more aggressive grip, there is a product available to meet your specifications. Options such as tooth washers, internal lock washers, and external lock washers provide the flexibility to address various engineering challenges. This versatility, combined with proven performance metrics, makes Tooth Lock Washers a must-have component for anyone serious about fastener technology.

The importance of selecting the right Tooth Lock Washers cannot be overstated. Accurate measurement, proper orientation, and adherence to recommended torque specifications are critical for maximizing their performance. Field experts advise that regular inspections and maintenance can help extend the life of the washers and ensure continued joint integrity. In high-stress environments where safety and reliability are paramount, these practices can make a significant difference in preventing mechanical failure and reducing downtime.

Investing in high-quality Tooth Lock Washers is a strategic decision that enhances both safety and operational efficiency. Their unique design, combining intricate tooth patterns with robust materials, provides an unparalleled level of security in bolted joints. This reliability is especially important in applications where failure is not an option. As more industries adopt advanced locking technologies, Tooth Lock Washers continue to set the standard for secure, durable fastening solutions. Their proven performance and ease of use make them a cornerstone of modern assembly techniques, ensuring that your joints remain tight and secure throughout their service life.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”

![260pcs[9 Sizes] Black Starlock Internal Tooth Lock Washers Assort...](https://m.media-amazon.com/images/I/41tkGfsvgOL._SL500_.jpg)

![Hilitchi 400-Pcs [8-Size] 304 Stainless Steel External Internal T...](https://m.media-amazon.com/images/I/619hIto9UyL._SL500_.jpg)

![[4-Pack] D-Shaped Washer - 1 in Trailer Axle Spindle - Flat Spot ...](https://m.media-amazon.com/images/I/41R0rp+0YmL._SL500_.jpg)