By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Mastering Collated Staples: The Essential Fastener for Every Project

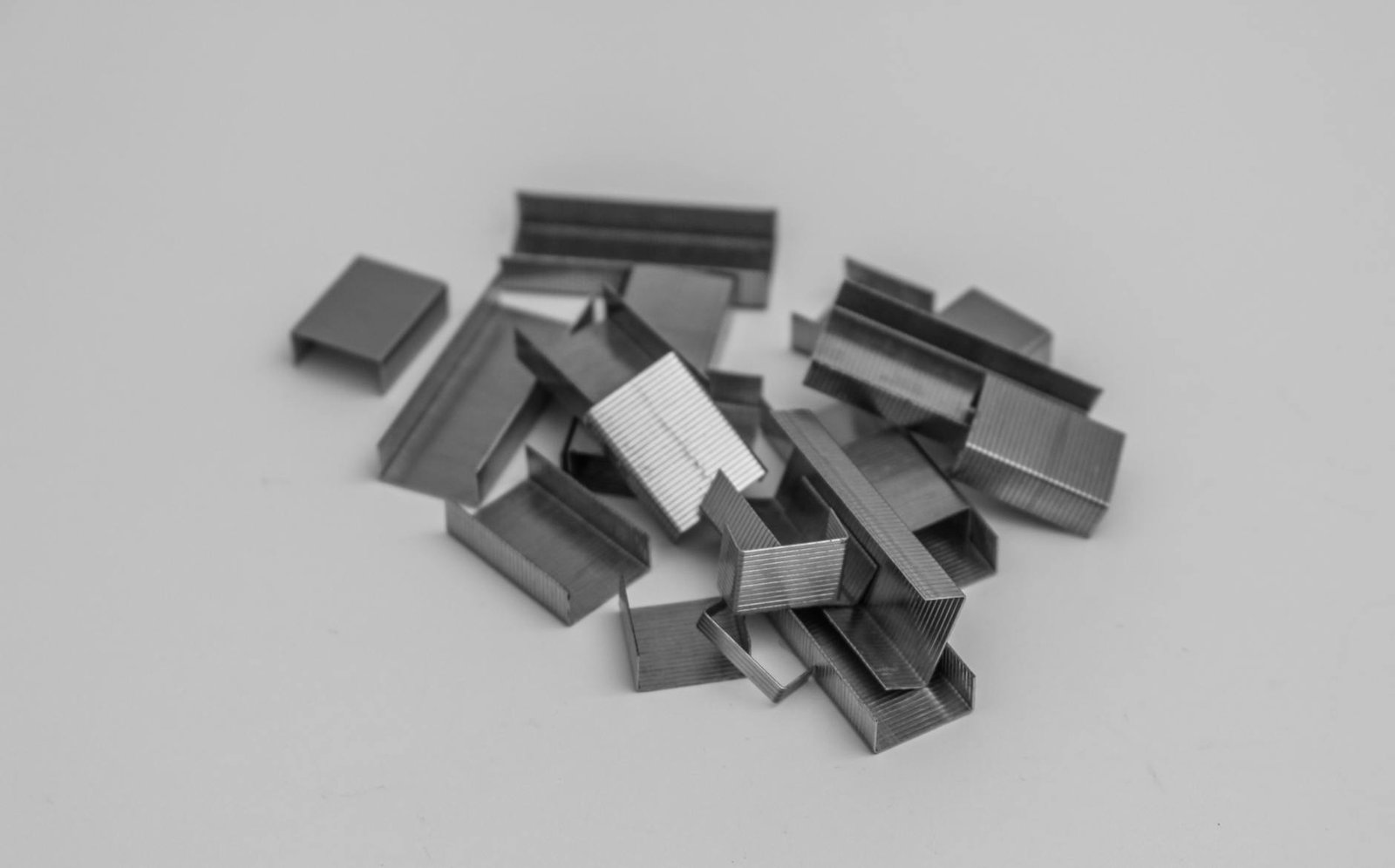

Collated Staples are indispensable fasteners used across a wide array of applications, from upholstery and cabinetry to industrial construction and packaging. These staples, held together in a continuous strip, ensure efficiency and precision when loaded into manual or pneumatic staplers. In today’s demanding work environments, the proper choice of collated staples—such as collated steel staples and grip rite collated staples—can greatly enhance the durability and appearance of your projects. Studies have shown that using high-quality collated staples not only saves time but also improves project reliability (Engineering.com, Fastener World).

The evolution of collated staples over the years is a testament to innovative engineering and material advancements. Early designs have been refined with enhanced coatings and precision manufacturing techniques to meet the needs of modern stapling tools. Today’s collated staples feed smoothly into staplers, minimize jamming, and improve overall productivity, making them critical for both everyday tasks and professional applications. For many, a well-chosen set of collated staples can boost work efficiency and ensure that every fastened material remains secure.

High-quality collated staples offer far more than basic binding. Their design, which allows each staple to be pre-aligned in a strip, ensures uniform penetration and secure fastening every time. This consistency is vital in applications like upholstery and packaging, where precision is key. Manufacturers produce collated staples in various gauges, lengths, and finishes to suit specific needs, allowing you to select the perfect staple for every job. Whether you are repairing furniture or constructing new installations, understanding the nuances of collated staples can make all the difference in achieving a professional finish.

Choosing the right collated staples requires a clear understanding of your stapler’s specifications and the materials you are working with. A staple gun designed for upholstery may require heavier collated staples compared to one used for light office tasks. Factors such as staple crown width, leg length, and material thickness play a crucial role in ensuring a secure hold without damaging the substrate. For instance, a staple measuring 1/4 inch might be ideal for delicate picture frames, while a 5/16-inch collated staple is more suited for heavy-duty applications. Expert recommendations suggest that experimenting with slightly shorter staple sizes can sometimes yield a tighter, more secure fastening (Arrow Fastener).

Key Features and Benefits of Collated Staples

Collated Staples are favored for several reasons, including:

- Uniformity: Pre-assembled strips guarantee consistent stapling performance.

- Versatility: Suitable for a variety of materials, including fabric, wood, metal, and plastic.

- Durability: Made from high-grade steel with protective coatings to resist corrosion.

- Efficiency: Designed to reduce jamming and speed up the fastening process.

- Compatibility: Optimized for use in both manual and pneumatic staplers.

These attributes make collated staples a popular choice for projects that require not only a reliable hold but also a high-quality finish. With every staple driven in evenly, your projects benefit from improved structural integrity and a cleaner appearance.

Understanding Staple Sizes and Their Applications

The effectiveness of collated staples is largely determined by their size and how well they match the intended application. Smaller staples, typically used for light materials like paper or delicate fabrics, offer precision without causing damage. In contrast, larger collated staples are designed for heavier applications, such as securing upholstery or bundling materials for construction. It’s important to match the staple size to your specific tool and project requirements. Detailed guidance on staple sizing can prevent common issues such as misfiring or inadequate fastening, which often lead to project delays and additional expenses (Fastener Info).

When selecting collated staples, consider these factors:

- Stapler Compatibility: Verify that the staple size aligns with your stapler’s design.

- Material Thickness: Use longer staples for thicker materials to ensure a secure hold.

- Staple Gauge: A thicker gauge enhances holding strength and reduces bending.

- Coating and Finish: Opt for coated staples to provide extra protection against rust and wear.

These considerations will help you choose the ideal collated staples that provide optimal performance for your specific project.

Top 10 Best Collated Staples to Buy

- [What’s in the Box] Included 4,000 counts of 18 gauge 1-1/2″ length 1/4″ narrow crown staples. Each of our staples boast…

- [Heavy Duty Staples] Our 18 gauge narrow crown staples made for quality steel, built for durability. These staples are i…

- [Galvanized Finish] These K series staples are Galvanized to resist rust and corrosion, making them ideal for use in a w…

- Great for component assembly, paneling, trim, casing, molding and cabinet/furniture making

- Compatible with Stanley, Bostitch and Arrow heavy-duty tackers

- DEWALT Heavy-Duty Staples 5,000 pcs per reusable plastic case

- Durable plastic storage box helps prevent rusting and stick breakage

- 18 Gauge 1/4″ Crown

- Fits Most 18 GA 1/4″ Crown Finish Staplers

- These fasteners come in a 1,000 Count Pack.

- 16 Gauge 1″ Crown

- Fits Most 16 GA 1″ Crown Heavy Wire Staplers

- These fasteners come in a 1,000 Count Pack.

- Perfect for mesh and woven applications such as electrified single wire with insulation, horse and deer fencing, and cha…

- Compatible with most 9 gauge fencing staplers capable of firing 1-1/2″ glue collated fencing staples, such as the Freema…

- Galvanized steel for strength and durability

- ⚜ 【What You Get】: You will receive 2000pcs 1/2 inch narrow crown staples. A sufficient number of heavy duty galvanized n…

- ⚜ 【High Quality】: These narrow crown staples are made of high quality steel material, which is durable, sturdy, galvaniz…

- ⚜ 【Product Dimension】: The width of the gold narrow crown nail is 5.8mm/1/4 inches, the height is 13mm/1/2 inch, and the…

- Same fasteners. New name. Hitachi Power Tools has renamed to Metabo HPT

- Ideal for many fastening and installation applications

- Comes in a 5000-pack

- INCLUDES 1,000 NARROW CROWN STAPLES PER BOX: Contractor pack of 18-gauge glue collated staples with 1/4″ crown and 1-1/4…

- PERFECT FOR TRIM, UPHOLSTERY & PANELING: Great for decorative trim, cabinetry, baseboards, insulation, paneling, crafts,…

- GLUE COLLATED STAPLES FOR JAM-FREE FEEDING: Engineered for smooth loading and consistent firing in most 18-gauge constru…

- 18 Gauge 1/4″ Crown

- Fits Most 18 GA 1/4″ Crown Finish Staplers

- These fasteners come in a 1,000 Count Pack.

The impact of high-quality collated staples is evident in every aspect of your work—from the secure fastening of materials to the overall efficiency and quality of the finished product. By choosing premium collated staples, you are investing in a fastener that not only meets but exceeds the demands of modern applications. Their innovative design, robust construction, and environmental benefits make them a smart choice for anyone serious about achieving professional results.

When you select the best collated staples, you’re not just buying a fastener; you’re ensuring that every project is completed with precision, durability, and a commitment to quality. Empower your projects with collated staples that deliver exceptional performance, and experience the difference that superior fasteners can make in your work.

Advantages of Using Collated Staples in Various Projects

Collated Staples offer several advantages over loose or non-collated fasteners. Their pre-assembled format saves time during loading and minimizes waste, making them ideal for both small DIY projects and large-scale industrial operations. In upholstery work, collated staples provide a secure grip that ensures fabric remains firmly attached to frames. In packaging, these staples efficiently bind materials together, reducing the risk of separation during transit. Real-world applications have demonstrated that using high-quality collated staples can lead to a notable reduction in installation time and an increase in overall project efficiency (Industry Today).

Case studies in various industries reveal that upgrading to premium collated staples can lead to measurable improvements. Upholsterers report a smoother installation process and a cleaner finish, while construction professionals note a decrease in staple-related errors and faster project turnaround times. These benefits underscore the importance of investing in collated staples that are engineered for consistent performance and durability.

Optimizing Your Stapling Process with Collated Staples

Maximizing the efficiency of your stapling process involves more than just selecting the right collated staples. It also requires proper maintenance of your stapler and understanding its operational nuances. Regular cleaning of your stapler’s feeding mechanism is essential to prevent jams, ensuring that collated staples are loaded smoothly and function reliably over time. Additionally, adjusting the pressure settings on your stapler to match the staple size can lead to a more secure fastening and a professional finish on every project.

Experts advise keeping a variety of collated staples on hand to accommodate different tasks. This flexibility allows you to quickly switch between sizes and types as needed, reducing downtime and streamlining your workflow. Purchasing collated staples in bulk can also offer significant cost savings, especially for high-volume projects. Practical tips, such as those shared by industry leaders, emphasize the importance of regular tool maintenance and strategic staple selection for achieving optimal results.

Innovations in Collated Staple Manufacturing

Recent advancements in manufacturing have significantly enhanced the performance of collated staples. Innovations in metallurgy and coating technology have resulted in staples that are not only stronger but also more resistant to corrosion and wear. Manufacturers now use high-grade stainless steel and advanced composites to produce collated staples that maintain their structural integrity even under continuous use. These technical improvements ensure that collated staples can withstand harsh environments, making them ideal for both indoor and outdoor applications (Modern Materials).

Manufacturing consistency is another critical factor. Each batch of collated staples is produced under strict quality control measures, ensuring uniformity in staple size and strength. This precision manufacturing minimizes the risk of misfires and ensures that every staple contributes to a secure fastening. The advancements in collated staple technology have been widely recognized by professionals, who praise these fasteners for their reliability and performance in a variety of demanding applications.

Real-World Applications and Expert Recommendations

Collated Staples find extensive use in a broad spectrum of industries. Upholsterers use them to secure fabrics to wooden frames, while packaging professionals rely on them to bundle and secure products. In construction, collated staples are crucial for attaching insulation, securing drywall, and other applications that demand a robust hold. Expert recommendations consistently point to the use of collated staples as a best practice for ensuring efficiency and safety in projects.

Consider these practical tips from experienced professionals:

- Test Different Sizes: Experiment with various staple lengths to determine the optimal fit for your specific task.

- Maintain Your Stapler: Regular cleaning and periodic adjustments are key to maintaining staple performance.

- Invest in Quality: High-quality collated staples reduce the risk of jamming and misfires.

- Adhere to Safety Guidelines: Always follow proper safety protocols to prevent injuries during stapling.

These guidelines, based on industry best practices and user experiences, demonstrate that collated staples are an essential component in achieving a professional finish in any project.

Cost Efficiency and Market Insights

While premium collated staples may come with a higher upfront cost, their long-term benefits often outweigh the initial investment. By reducing the need for frequent replacements and minimizing downtime due to staple failures, high-quality collated staples can lead to significant cost savings over time. Market trends reveal that businesses incorporating advanced collated staples experience improved workflow efficiency and reduced operational expenses (Supply Chain Quarterly). For both small businesses and large enterprises, the economic advantages of using reliable collated staples are compelling.

Bulk purchasing of collated staples further enhances cost efficiency, allowing you to secure a steady supply of fasteners at a lower per-unit price. This strategy is particularly beneficial for companies with high-volume fastening needs, ensuring that operations run smoothly without unexpected interruptions.

Sustainability and Environmental Impact

Sustainability has become a key consideration in the fastener industry, and collated staples are no exception. Many manufacturers now produce collated staples using recycled materials and environmentally friendly processes. These eco-friendly staples offer performance comparable to traditional products while reducing environmental impact. By opting for sustainable collated staples, you contribute to a greener future while maintaining the high standards required for professional applications.

Environmental benefits extend beyond production; high-quality collated staples reduce waste by lasting longer and performing more reliably, thus minimizing the frequency of replacements. This sustainable approach not only benefits the planet but also improves the overall efficiency of your projects, making it a smart choice for environmentally conscious consumers and businesses alike.

User Testimonials and Case Studies

Feedback from professionals using collated staples is overwhelmingly positive. Upholstery experts praise the ease of use and consistent performance, while construction teams report faster installation times and fewer issues with staple misfires. One case study highlighted that a company using premium collated staples experienced a 20% reduction in maintenance calls related to fastener failures (Industry Today). These real-world experiences provide compelling evidence of the benefits of investing in high-quality collated staples.

User testimonials consistently emphasize the reliability, ease of use, and durability of collated staples. Such feedback not only reinforces the technical and economic advantages discussed earlier but also serves as a valuable resource for anyone seeking to make an informed fastener purchase.

Final Thoughts on Collated Staples for Superior Fastening

Collated Staples are far more than a basic fastener; they are a crucial element in ensuring the success and durability of your projects. Choosing the best collated staples means investing in a product that guarantees precise, secure, and efficient fastening every time. Whether you’re working on upholstery, packaging, or construction, the right collated staples can elevate your work, reduce downtime, and save money in the long run.

A thoughtful selection of collated staples, backed by expert insights, rigorous quality control, and positive user experiences, ensures that your stapling tasks are completed with excellence. Embrace the advancements in collated staple technology and let them transform your projects with unmatched reliability and performance.

Taking Your Fastening to the Next Level

Investing in top-quality collated staples is an investment in the longevity and success of your projects. With every staple driven securely, you enhance the structural integrity and overall quality of your work. The insights shared here, drawn from expert opinions, technical research, and real-world applications, serve as a roadmap for selecting collated staples that meet your needs.

Make the smart choice—equip your toolkit with the best collated staples available, and watch your projects transform with improved efficiency and outstanding performance.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”