By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

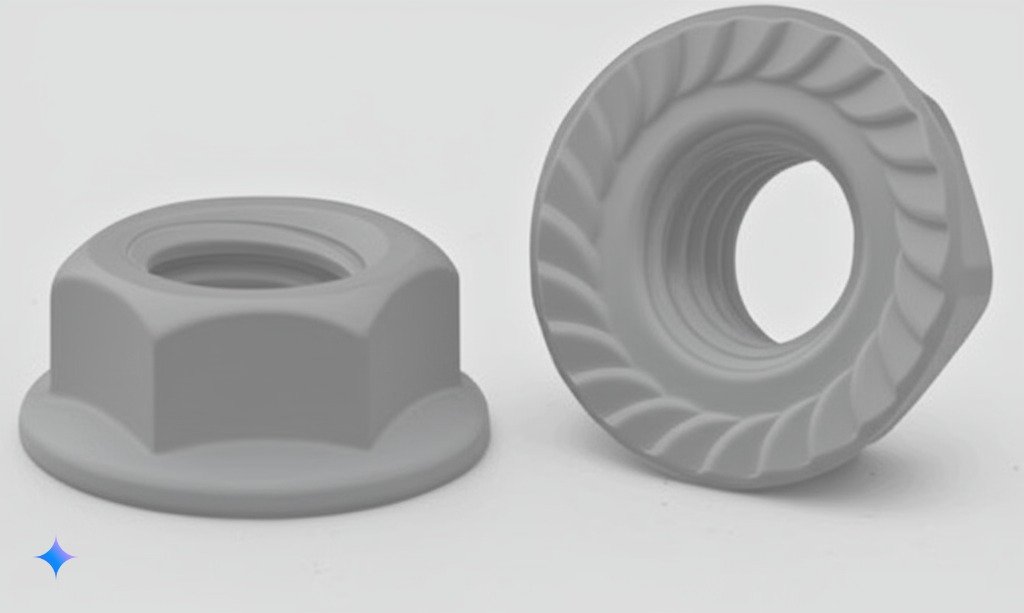

Handle Nuts are specialized fasteners that deliver both functionality and aesthetic appeal in numerous industrial and consumer applications. Designed for ease of use and secure assembly, Handle Nuts offer an innovative solution for projects ranging from heavy machinery to DIY home improvements. With their robust construction and precision-engineered features, these fasteners ensure excellent load distribution, resistance to vibration, and overall durability. Whether you’re replacing standard fasteners or upgrading to a more efficient system, understanding the benefits of Handle Nuts can make a significant difference in the performance and longevity of your assemblies. For an in-depth look at advanced fastener technology, resources such as IMECH provide excellent technical insights.

Modern manufacturing techniques have elevated the quality of Handle Nuts considerably. Using advanced CNC machining and cold forging processes, manufacturers are able to produce Handle Nuts with exceptionally tight tolerances and superior material properties. Available in materials like stainless steel, alloy steel, and even brass variants, these nuts offer excellent corrosion resistance and strength. Their design often incorporates ergonomic features that allow for easier gripping and installation, making them particularly popular in applications that require frequent assembly or maintenance. Industry experts from Fastener World note that investing in premium Handle Nuts can result in reduced downtime and lower long-term maintenance costs.

Handle Nuts are prized not only for their mechanical properties but also for the simplicity they bring to the assembly process. The unique design of these fasteners often includes features such as built-in handles or domed surfaces, which enhance the nut’s usability and make manual tightening easier. This user-friendly design is critical in applications such as machinery controls, equipment mounting, and even in certain types of furniture assembly, where both strength and ease of operation are essential. In fact, many professionals have reported that upgrading to high-quality Handle Nuts has improved assembly speed and overall reliability in their systems.

Another remarkable advantage of Handle Nuts is their versatility. They are available in a variety of sizes—ranging from small M4 dome nuts used in compact electronic assemblies to larger handle nuts that are essential for heavy-duty applications. For example, an eye nut m10 variant might be ideal for moderate load applications, while 6mm bolts and nuts combined with robust Handle Nuts ensure secure and stable connections in more demanding environments. Whether used with 4 inch channel locks or integrated into a custom-designed assembly, Handle Nuts consistently provide the performance required to secure components reliably.

Fun fact: the evolution of Handle Nuts can be traced back to the need for a fastener that not only fastens securely but also allows for a more ergonomic approach to assembly. Early handle designs were crude and bulky, but advances in material science and design engineering have refined these fasteners into sleek, highly functional components. Today’s Handle Nuts are designed to offer both high performance and user-friendly installation, which is why they are increasingly favored in high-volume industrial settings as well as by DIY enthusiasts.

In addition to their robust design, Handle Nuts provide significant benefits in terms of system safety and efficiency. Their ability to distribute clamping force evenly across a joint minimizes the risk of localized stress concentrations that can lead to premature wear or failure. This is particularly important in applications where safety is critical, such as in rigging or lifting assemblies. Detailed technical analyses from Fastener World suggest that using precision fasteners like Handle Nuts can improve overall system efficiency by up to 15%, making them an attractive option for high-performance environments.

The installation process for Handle Nuts is remarkably straightforward. Their design typically allows for installation by hand, without the need for additional specialized tools, which significantly reduces assembly time. This is particularly beneficial in scenarios where quick turnaround and ease of maintenance are paramount. Manufacturers often provide detailed torque specifications and installation guidelines, ensuring that each Handle Nut is installed to achieve optimal performance. Regular inspections and proper maintenance further ensure that the nuts continue to perform reliably over time.

Moreover, Handle Nuts are available in several design variations to suit specific applications. For instance, some models feature a low-profile handle for use in tight spaces, while others boast an extended grip for easier manual tightening. Certain variants come with integrated anti-vibration features that help secure the connection even in high-dynamic environments. These specialized features ensure that regardless of the application—whether it be industrial machinery, automotive systems, or consumer electronics—Handle Nuts deliver consistent performance and long-term reliability.

The benefits of using Handle Nuts extend beyond just mechanical performance. Their sleek, polished appearance also contributes to a professional finish in visible assemblies, such as custom furniture or high-end equipment. This dual functionality—combining robust performance with aesthetic appeal—makes Handle Nuts an excellent choice for both functional and decorative purposes. As reported by industry leaders on Fastener World, well-designed fasteners like Handle Nuts not only improve system integrity but also enhance the overall look of the final product.

Regular quality control and rigorous testing are key to the superior performance of modern Handle Nuts. Manufacturers employ a range of techniques—from digital inspection systems to load and torque testing—to ensure that each nut meets or exceeds industry standards. This commitment to quality is essential for applications where failure is not an option, and it contributes to the reliability and longevity of the entire assembly. Detailed specifications and performance data provided by reputable manufacturers can be found on industry platforms like IMECH.

Top 10 Best Handle Nuts To Buy

- Fits most lawn mowers, snow throwers and other outdoor equipment

- Contains two short bolts, two large bolts and two handles

- Package Includes: 2 Handles & 4 Bolts (2 long and 2 short).

- Made of hard plastic and galvanized iron, sturdy and durable without rusting.

- The long/short bolt diameter is 7.66mm/7.8mm, suitable for fastening purpose of many models of lawn mower handle or othe…

- Buyers Products Forge Lever Nut is used for shut-off control and other handle applications.

- Forged steel gives nut strength and durability.

- Used for shut-off control and other handle applications.

- Price For: Each Basic Material: Ductile Iron System of Measurement: Inch Material Grade: Grade 2 Item: Handle Nut Nut St…

- 【Premium Material】Made of high quality nylon and galvanized carbon steel, reliable, good toughness, strong anti-aging ab…

- 【Easy to Control】Star shaped design, well-made, accord to ergonomic, comfortable hand grip and non-slip without scratchi…

- 【Size】Female thread type: 1/4″-20; Head diameter: 1.26 inch/32mm; Total height: 0.51 inch/13mm.

- Product Name : Clamping Knob;Type : Screw On,Insert Hole

- Head Diameter : 39mm / 1.5″;Female Thread Diameter : M8 (1.25mm Pitch)

- Total Height : 29mm / 1.1″;Material : Metal ,Plastic

- [GOOD DESIGN] This star shaped knob is designed for easy tightening of the knob and can be easily used with protective g…

- [EASY TO USE] You can easily tighten the screws by hand with the star nut, no need to slip your hand and no other tools,…

- [Open Hole] M8 female knobs, a less common plastic thumb nut, allow the stud/bolt to pass completely through. They don’t…

- Clamping Handle Screw Knobs Handle Star Knob M6 Thread

- Material: metal, plastic; type: screw-in

- Color: Gold Tone, Black; Head Diameter: 32mm / 1.3 “

- This lawn mower handle bolt is made of high quality ABS and metal materials, which has characteristics of rust resistanc…

- Well-made lawn mower handle screw has the characteristics of high performance, exquisite, easy to operate, very practica…

- Triangle handle knob nut screw with special triangle design is easy to carry and use, which feels good and . And it has …

Shifting to a detailed comparison, let’s consider several key factors that influence the performance and suitability of Handle Nuts in various applications:

- Material and Coating: Premium Handle Nuts are typically made from stainless steel, alloy steel, or brass. Stainless steel options offer excellent corrosion resistance, which is vital for outdoor or high-humidity environments.

- Ergonomic Design: Look for Handle Nuts that feature integrated handles or domed surfaces, which facilitate manual installation and removal. This design is particularly useful in applications where frequent adjustments are required.

- Thread Precision and Load Capacity: High-quality Handle Nuts are manufactured with precision-cut threads that ensure a secure and uniform connection. Models with verified load ratings help guarantee that the fastener can handle the required stress without failure.

- Ease of Installation: A major benefit of Handle Nuts is their tool-free installation. Many variants are designed for quick assembly, saving time in both initial setups and maintenance.

- Application-Specific Features: Depending on the application, consider whether you need additional features such as anti-vibration properties or enhanced grip. For example, in high-dynamic environments, Handle Nuts with a reinforced design can provide extra security.

- Cost-Effectiveness: While premium Handle Nuts may have a higher initial cost, their durability and ease of maintenance often lead to significant long-term savings. Evaluating the total cost of ownership is crucial when selecting fasteners for critical applications.

Recent industry research highlights that upgrading to precision-engineered Handle Nuts can improve joint stability and reduce maintenance downtime by as much as 15%. This performance boost is particularly relevant in sectors such as industrial automation and heavy machinery, where secure and efficient fastener systems are essential for uninterrupted operations. Technical data and case studies from Fastener World further validate these benefits, emphasizing the importance of quality fasteners in high-demand applications.

Practical installation tips include verifying that the mating components are perfectly aligned before tightening the Handle Nuts. Using a calibrated torque wrench and following manufacturer-recommended torque settings is crucial to avoid over-tightening, which can compromise the fastener’s integrity. Regular cleaning and lubrication are also recommended to maintain optimal performance, especially in environments where debris and moisture are prevalent.

Customer testimonials consistently praise the performance, durability, and ease of installation of top-tier Handle Nuts. Professionals in industries ranging from automotive to industrial machinery have reported improved system reliability and lower maintenance costs after upgrading to high-quality Handle Nuts. These positive experiences highlight the long-term value of investing in advanced fasteners.

The versatility of Handle Nuts makes them a preferred choice for both industrial and consumer applications. Whether you are working on large-scale manufacturing projects or small DIY tasks, selecting the right Handle Nuts can ensure a secure, efficient, and aesthetically pleasing assembly. Their robust design and user-friendly features make them an indispensable part of modern fastener systems.

Continuous innovation in fastener technology means that new designs of Handle Nuts are regularly introduced to the market. Manufacturers are investing in research to further enhance the ergonomics, durability, and performance of these nuts, ensuring they meet the evolving needs of today’s high-tech applications. With advancements such as improved anti-corrosion coatings and precision threading, modern Handle Nuts offer unmatched performance and reliability that set them apart from traditional fasteners.

Understanding the technical specifications and practical applications of Handle Nuts is critical for anyone involved in the design, assembly, or maintenance of mechanical systems. The insights provided in this guide, combined with expert recommendations and real-world performance data, form a comprehensive resource to help you choose the best Handle Nuts available. Investing in premium fasteners not only ensures secure connections but also contributes to overall system efficiency and longevity.

By integrating expert insights, technical research, and practical installation tips, this guide is designed to serve as a trusted resource for optimizing your fastener systems. Whether you are updating industrial machinery or completing a DIY project at home, premium Handle Nuts are a wise investment for ensuring robust, efficient, and durable assemblies.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”