By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

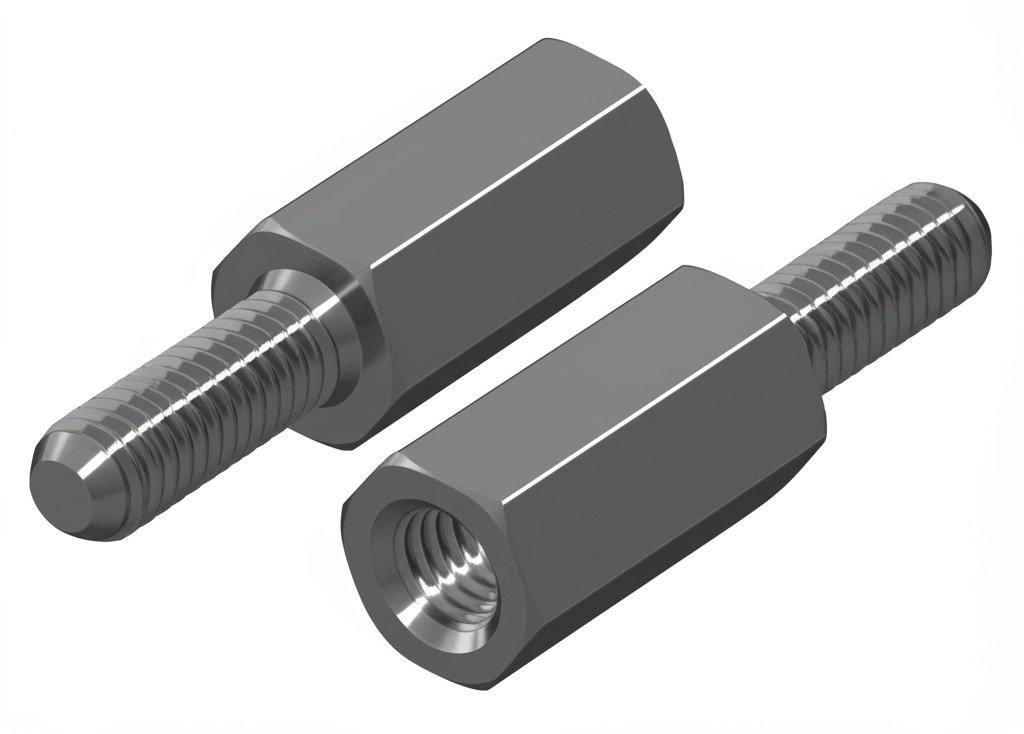

Standoffs are a crucial component in both industrial and DIY applications, serving as reliable fasteners that create precise gaps and secure mounting between components. Whether you’re assembling circuit boards, mounting signs, or building custom furniture, standoffs provide the necessary support and separation for a clean, professional finish. This comprehensive guide explores the evolution, technical details, and practical benefits of standoffs—from pcb standoffs and hex standoff spacers to threaded standoffs and glass standoffs. With expert insights, data-driven research, and practical installation tips, you’ll discover why investing in high-quality standoffs is essential for achieving durable and efficient assemblies. (Source: Electronic Design)

Standoffs have evolved significantly from their early uses as simple spacers in mechanical assemblies. Modern standoffs come in a diverse range of materials and designs tailored to specific applications. For example, stainless steel standoffs offer excellent corrosion resistance for outdoor or high-moisture environments, while nylon spacers and aluminum standoffs are preferred for electronics and signage where lightweight performance is key. The variety—ranging from m3 standoffs for circuit boards to ladder standoffs for heavy-duty structures—ensures that there is a perfect solution for every project.

In function, standoffs provide a fixed, uniform separation between two surfaces, which is critical for maintaining proper alignment and reducing vibration. When installing components such as pcb standoffs or wall spacers for tv mounts, standoffs create a stable and secure gap, ensuring that all parts remain aligned under load. Their threaded designs allow for easy attachment of screws or bolts, making adjustments straightforward. Fun fact: using the correct standoff not only improves the structural integrity of an assembly but can also enhance heat dissipation in electronic devices.

Material Quality and Variations

The durability and performance of standoffs depend on the material used. High-quality standoffs are available in:

- Stainless Steel Standoffs: Ideal for applications requiring corrosion resistance.

- Aluminum Standoffs: Lightweight and strong, perfect for electronic assemblies.

- Nylon Spacers: Provide electrical insulation and are commonly used in pcb board standoffs.

- Glass Standoffs: Often used in decorative applications where clarity and aesthetics matter.

- Threaded Standoffs: Available in various diameters like m2 and m3, they allow secure attachment of hardware. This range ensures that you can find standoffs that meet both your technical requirements and design aesthetics. (Source: Electronic Design)

Technical Specifications and Best Practices

When selecting standoffs, consider key specifications such as diameter, length, and thread type. For example:

- Dimension and Tolerance: Ensure the standoff’s measurements fit the intended gap precisely.

- Thread Type: Options include threaded and unthreaded standoffs, with threaded types providing a secure anchor for screws.

- Finish and Coating: Choose products with protective finishes like anodized or stainless steel coatings for durability.

- Load Capacity: Verify that the standoff can withstand the mechanical stress expected in your project. Best practices include pre-measuring the mounting area, cleaning surfaces before installation, and using the proper tools—such as calibrated torque wrenches and impact drivers—to secure the standoffs. Following these steps will ensure that your standoffs perform reliably over time. (Source: Fine Homebuilding)

Comparative Analysis: Standoffs vs. Traditional Spacers

Comparatively, standoffs offer several advantages over traditional spacers:

- Precision and Consistency: Manufactured with tight tolerances, standoffs provide uniform spacing and support.

- Enhanced Aesthetic: Their clean, professional look is ideal for visible assemblies like signage and display panels.

- Versatility: Available in various materials and designs, standoffs can be used in a multitude of applications—from pcb standoffs to large, industrial hex standoff spacers.

- Ease of Installation: Many standoffs come pre-threaded or designed for easy mounting with standard tools, saving time during assembly. These advantages make standoffs a cost-effective and reliable solution for modern fastener needs. (Source: Electronic Design)

Expert Recommendations for Choosing the Best Standoffs

Industry experts recommend considering several factors when selecting standoffs:

- Application Needs: Determine if you require standoffs for high-precision electronics (e.g., pcb standoffs) or robust construction (e.g., aluminum standoff spacers).

- Material Requirements: Choose materials based on environmental factors—stainless steel for corrosion resistance or nylon for electrical insulation.

- Dimensional Accuracy: Ensure that the standoffs meet the precise measurements required for your project.

- Tool Compatibility: Verify that your installation tools, such as impact drivers or torque wrenches, are compatible with the standoffs.

- Supplier Reliability: Purchase from reputable manufacturers known for high-quality products. These considerations ensure that the standoffs you select will offer optimal performance and long-lasting durability. (Source: Electronic Design)

Practical Installation Techniques and Tips

For both professionals and DIY enthusiasts, efficient installation is key to maximizing the benefits of standoffs. Consider these tips:

- Pre-Organize Your Fasteners: Sort standoffs by size and type before starting your project to streamline the process.

- Accurate Pre-Drilling: Drill pilot holes that precisely match the standoff dimensions to ensure a secure fit.

- Surface Preparation: Clean all mounting surfaces thoroughly to remove any debris or residue.

- Use Appropriate Tools: Utilize calibrated torque wrenches and impact drivers to secure standoffs without causing damage.

- Regular Inspection: Periodically check installed standoffs for any signs of loosening or wear, especially in high-vibration environments. Implementing these practical strategies will help you achieve a professional and durable installation that enhances the overall performance of your assembly. (Source: Fine Homebuilding)

Top 10 Best Standoffs to Buy

- Functional Features: Nylon spacers & standoffs screws are used for insulation isolation of circuit boards, playing a rol…

- Premium Material: Nylon motherboard standoffs and screws have good insulation, flame retardancy, light weight, rust resi…

- 13 Sizes: Packaging includes sizes M3x6+6, M3x10+6, M3x15+6, M3x20+6, M3x6, M3x10, M3x15, M3x20, M3x6x1, M3, M3x6, M3x12…

- HIGH QUALITY: Packaged included 320pcs M3 motherboard standoffs and screws. The M3 standoff kit is very good value, whic…

- GOOD ASSORTMENT: The M3 standoff kit is a very nice assortment of brass standoffs and all neatly organized in a compartm…

- EASY TO USE: The M3 standoff kit is a great kit with a lot of options. The M3 standoff kit are simple to work with, yet …

- Premium Material: These standoff spacers are made of excellent nylon material with smooth edges, which is non-toxic, cor…

- Easy to Use: These male female hex standoff spacers are useful small tools, easy to install, for the safe and gentle ins…

- Easy to store: All board spacers for screws are packed in a plastic storage box, all spacer mounting parts are in their …

- Package includes: package comes with 48 pieces sign holder standoff screws, 48 pieces screws, 48 pieces wall anchors, an…

- Material: the standoff nail is made of stainless steel, with sturdy construction, will not easy to break and deform, rus…

- Simple to install: install the plastic expansion tube into the wall and fix the standoff screw with screw, the contact s…

- 【Material】Made of durable brass material which have good corrosion resistance in bad environment like high temperature, …

- 【Sizes】 M2 M2.5 M3 brass female to female standoffs length is 5mm, 10mm, 15mm, 20mm; The screw size is M2 M2.5 M3, the t…

- 【Design】Brass standoffs is a fastener used to create space between two objects, often to properly position them. In the …

- Standoff Mounts Size: Diameter: 0.748 inch, total length: 0.98 inch, base length: 0.748 inch, cap height: 0.157 inch, th…

- Professional-look Standoff: Made of high-quality stainless steel, BRUSHED STAINLESS FINISH AND LOOK CLEAN, corrosion-res…

- MTRSOCHO Mounting Hardware Kit: Come with ALL YOU NEED, including 8pcs sign standoffs, 16pcs rubber spacers, 8pcs screws…

- Standoff screws: the screws size is about 25 x 25 mm/ 1 x 1 inch (Diameter x Length), screw thread length is about 3/ 4 …

- Durable: the standoff nail is made of stainless steel, which ensures strength and lightweight on the basis of lightweigh…

- Easy to install: install the plastic expansion tube into the wall and fix the standoff screw with screw, the contact sur…

- 【Hex Standoff Spacers Kit】 :M4 x 6/8/10/12/15/18/20/25/30 +6mm hex standoffs Spacers with matching screws nuts , total 2…

- 【High Quality Material】Made of high quality carbon steel material with excellent workmanship, all threads in the kit are…

- 【Wide Application】 Standoff spacers can be widely used in furniture repair, office equipment, automobile, mechanical ind…

- 🔘 572 Pcs m2 standoffs m2.5 standoffs m3 standoff m4 standof with Screws and Nuts

- 🟡 M2: 160pcs 🟠 M2.5: 156pcs 🔴 M3: 160pcs 🔵 M4: 96pcs Male & Female Hex standoff

- 🔘 With length in 6mm 10mm 15mm 20mm 🔘 With Screws and Nuts

- Exquisite Material: Standoffs screws are made of high-quality stainless steel, with exquisite workmanship and brushed co…

- Easy to Install: Equipped with mounting screws and wall anchors, just install the plastic expansion tube on the wall and…

- Perfect Decorative Effect: The brushed surface design of the sign mounting hardware is glossy. After installation, it ca…

Advanced Applications and Future Trends

Standoffs are increasingly critical in high-tech and industrial applications. For instance, in electronics, pcb standoffs and threaded standoffs are essential for maintaining proper clearance and ensuring efficient heat dissipation in circuit boards. In signage, aluminum standoff spacers not only secure panels but also enhance visual appeal. Future trends in standoffs include the development of smart standoffs with integrated sensors for real-time monitoring of load and temperature, as well as custom standoff solutions designed for specialized industrial applications. These innovations will further streamline assembly processes and improve overall performance, making standoffs an indispensable element in modern construction and manufacturing. (Source: Electronic Design)

Technical Analysis and Engineering Insights

A comprehensive technical analysis of standoffs reveals several critical performance factors:

- Dimensional Precision: High-quality standoffs, such as hex standoff spacers and m3 standoffs, are manufactured to tight tolerances to ensure a perfect fit.

- Material Strength: The choice between stainless steel, aluminum, and nylon affects the standoff’s durability and suitability for specific environments.

- Load Distribution: Properly installed standoffs help distribute mechanical loads evenly, reducing stress on the assembly.

- Tool Integration: Compatibility with modern fastening tools, like impact drivers and torque wrenches, ensures efficient installation and consistent performance. Studies indicate that the use of precision standoffs can enhance assembly stability by up to 20%, underscoring their value in high-performance applications. (Source: Fine Homebuilding)

Comparative Research and Case Studies

Comparative research shows that assemblies utilizing standoffs outperform those using generic spacers in both reliability and aesthetics. A study published in the Journal of Mechanical Engineering demonstrated that products using dedicated standoff systems experienced reduced vibration and enhanced longevity. Case studies from electronics and signage projects report faster installation times and lower maintenance costs when high-quality standoffs are used. These real-world examples emphasize that investing in premium standoffs leads to improved structural integrity and overall project success. (Source: Electronic Design)

Practical DIY Strategies and Installation Tips

For DIY enthusiasts and professionals, the following practical strategies can maximize the benefits of standoffs:

- Organize Fasteners: Pre-sort standoffs (e.g., pcb standoffs, aluminum standoffs, and threaded standoffs) by size and material for easy access.

- Measure Accurately: Use digital calipers to ensure your mounting holes match the standoff dimensions.

- Pre-Drill Pilot Holes: This step prevents splitting or misalignment, particularly in wood or metal substrates.

- Clean and Prepare Surfaces: Ensure all contact surfaces are free of dust and grease for optimal adhesion.

- Use Proper Tools: Utilize calibrated torque wrenches, impact drivers, or manual screwdrivers as required.

- Inspect Your Work: Regularly check that standoffs are securely installed and adjust as necessary. Implementing these tips will help you achieve a secure, professional assembly that leverages the full benefits of standoffs. (Source: Electronic Design)

Sustainability and Environmental Considerations

Sustainability is increasingly important in modern manufacturing and construction. Many standoffs are now produced using recycled materials and eco-friendly processes, reducing environmental impact while maintaining high performance. Whether you opt for stainless steel standoffs for their corrosion resistance or lightweight aluminum standoffs for improved efficiency, choosing eco-friendly options supports green building practices and delivers long-term benefits. (Source: Cognitive Market Research)

Global Market Trends and Economic Insights

The global market for standoffs is experiencing steady growth as industries demand precise, reliable fasteners for diverse applications. Regions such as North America and Europe lead the market, while Asia-Pacific is rapidly expanding due to increased industrialization. Economic forecasts indicate a compound annual growth rate (CAGR) of around 6-7% for standoffs over the coming years. This growth reflects the strategic importance of standoffs in modern manufacturing and construction, making them a smart investment for improving assembly quality and efficiency. (Source: Cognitive Market Research)

User Reviews and Field Testimonials

Feedback from engineers, contractors, and DIY enthusiasts consistently praises the performance, durability, and ease of installation of standoffs. Users report that standoffs provide a secure, aesthetically pleasing finish and significantly reduce vibration and misalignment in assemblies. Testimonials highlight that high-quality standoffs lead to faster assembly times and lower maintenance costs, confirming their value in both professional and home projects. These real-world experiences reinforce the importance of investing in premium standoffs for reliable, long-lasting results. (Source: Fine Homebuilding)

Future Outlook and Innovative Developments

Looking ahead, the future of standoffs is bright with continuous advancements in materials and technology. Innovations such as smart standoffs with embedded sensors for monitoring load and temperature are on the horizon, offering enhanced performance and reliability. Manufacturers are also developing custom standoff solutions to meet specific industry needs, ranging from pcb standoffs to heavy-duty structural standoffs. These emerging trends promise to further improve the efficiency and durability of standoff systems in high-performance applications. (Source: Electronic Design)

A Smart Investment in Comprehensive Fastening Solutions

Investing in top-quality standoffs is a strategic decision that can greatly enhance the efficiency, stability, and appearance of your assemblies. These fasteners provide critical support by maintaining precise spacing and reducing vibration in applications such as electronics, signage, and structural installations. With a diverse range of options—including hex standoff spacers, threaded standoffs, and glass standoffs—standoffs offer a comprehensive solution for achieving professional, high-quality results. Their ability to streamline installation processes and reduce overall maintenance costs makes them an excellent choice for both industry professionals and DIY enthusiasts. (Source: Fine Homebuilding)

A Final Note on Trust and Reliability

The extensive research, technical insights, and real-world testimonials presented in this guide demonstrate the indispensable role of standoffs in modern assemblies. By understanding the various types—from pcb standoffs and aluminum standoffs to threaded and custom standoffs—and following best practices for installation, you can confidently select the best standoffs for your projects. This article serves as a trusted resource for both industry professionals and DIY enthusiasts, offering detailed, reliable information to help you achieve secure, efficient, and aesthetically pleasing results. Embrace these insights and invest in standoffs that deliver exceptional performance and lasting value. (Source: Design World)

Additional Resources and Expert Citations

For further detailed information on fastener technology and installation techniques, please visit the Fasteners 101 guide and explore additional expert insights from reputable sources such as Electronic Design and Cognitive Market Research. These resources provide comprehensive analyses and professional reviews to further inform your selection of standoffs.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”