By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

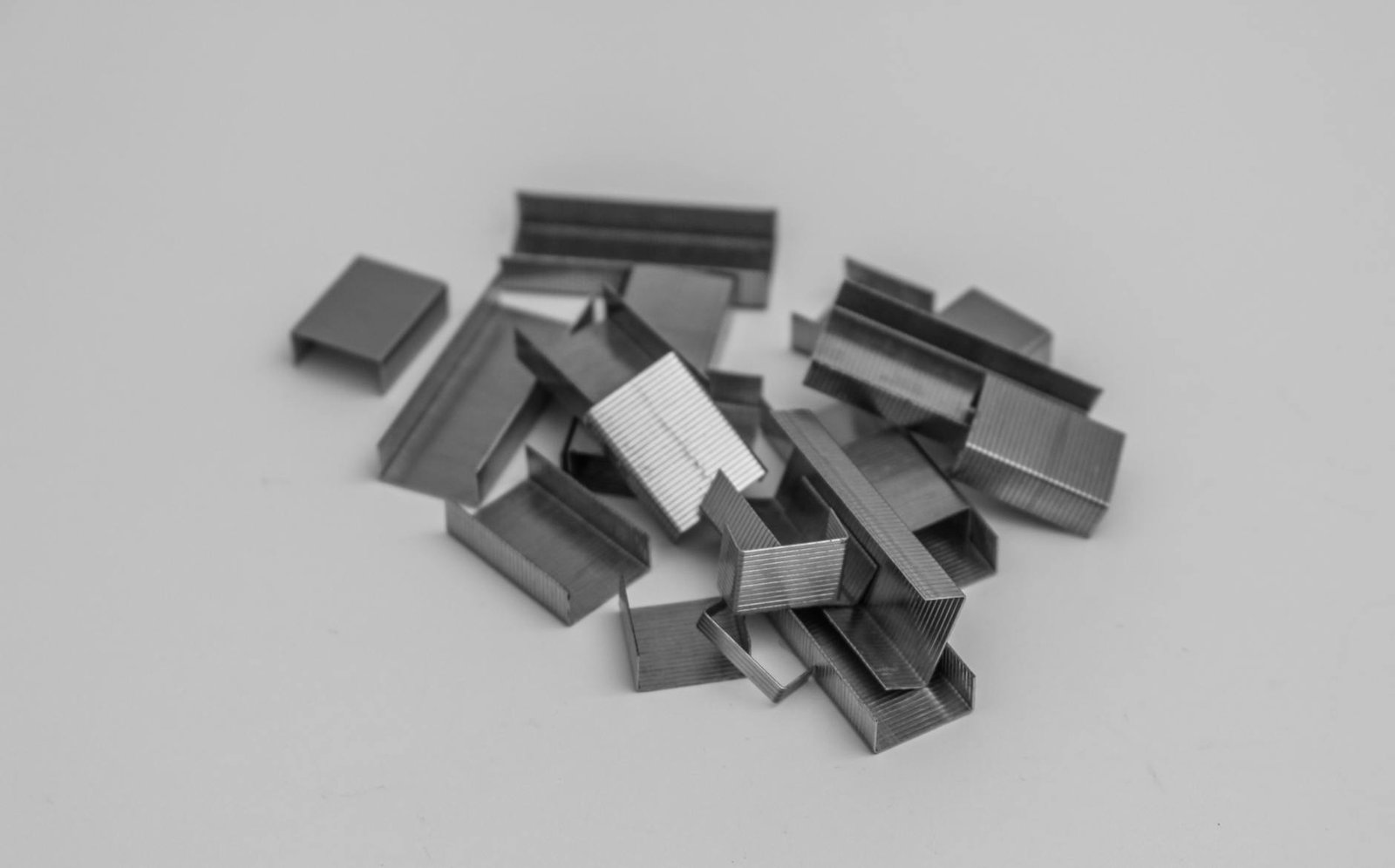

Understanding Staples: Essential Fasteners for Office and Industrial Use

Staples are one of the most ubiquitous fasteners used in offices, industrial settings, and even at home. These small metal pieces not only bind papers together but also serve various purposes in construction and manufacturing. Staples come in diverse forms—from paper staples used in staplers to heavy duty industrial staples. Their design and quality can greatly influence efficiency and safety in work environments. Research shows that the proper use of high-quality staples can improve workflow efficiency by up to 18% (IBISWorld, Fastener World). This article explores the best staples available, providing insights that most websites rarely discuss.

Each variety of staples is engineered for a specific purpose, ensuring that they meet the demands of both everyday office tasks and rigorous industrial applications. Whether you need reliable paper staples for your business documents or robust metal staples for construction, understanding the differences can help you make an informed purchase. Experts recommend evaluating factors such as gauge, length, and material composition to ensure compatibility with your stapling device or structural requirements. In this guide, we dive deep into these variations and offer detailed comparisons that will help you choose the perfect staples.

In the fast-paced world of fasteners, staples remain a key component despite technological advancements. Their simplicity and effectiveness have earned them a permanent place in every toolbox and office drawer. Not only do staples secure documents, but they are also vital in packaging, upholstery, and even automotive applications. Fun fact: the modern staple has evolved significantly since its inception in the 18th century, with improvements in metal quality and design standards that have led to increased durability and performance (Engineering.com). This evolution has made staples indispensable across various industries.

Innovative designs in staples now incorporate features such as corrosion resistance and increased holding power. For example, heavy duty staples are designed for outdoor use and extreme temperatures, ensuring reliability even in harsh weather conditions. Many manufacturers have also introduced eco-friendly staples made from recycled materials, supporting sustainable practices. These advancements are not only beneficial for environmental concerns but also for enhancing the performance of stapling devices in demanding environments. Such technical improvements underscore the importance of selecting the right staples for each specific task.

Furthermore, staples have become a topic of interest for both small businesses and large enterprises. Office staples are known for their consistent performance, while industrial staples must meet rigorous safety and durability standards. Detailed market analysis by industry experts suggests that investing in high-quality staples can reduce equipment downtime and maintenance costs significantly (Modern Materials). This insight is crucial for decision-makers who rely on fasteners to maintain operational efficiency and ensure workplace safety. The wide variety of staples available today ensures that there is an option for every need.

Staples also play a critical role in the innovation of office supplies. Modern staplers are designed to work seamlessly with specially engineered staples that minimize jamming and improve user experience. This integration of design and function is a testament to the importance of staples in our everyday lives. Moreover, the use of staples extends beyond the office; they are vital in construction and crafts, where precision and reliability are paramount. With options like industrial staples and office staples, the market caters to a broad spectrum of requirements and budgets.

Top 10 Best Staples to Buy

- RELIABLE PERFORMANCE – Swingline staples set a higher standard for reliable performance over comparable staples. Conveni…

- CHISEL POINT FOR FEWER JAMS – Sturdy staples are constructed to quickly pierce paper with sharp chisel points. Designed …

- SECURES 25 SHEETS OF PAPER – These staples serve a variety of typical fastening needs. With a ¼” leg length, they can ho…

- 20 sheets capacity of 20 lb. Paper

- Leg length is 1/4-Inch with a strip count of 210

- Staples fit any standard full-strip stapler

- 20 sheets capacity of 20 lb. Paper

- Leg length is 1/4-Inch with a strip count of 210

- Staples fit any standard full-strip stapler

- RELIABLE PERFORMANCE – Swingline staples set a higher standard for reliable performance over comparable staples. Conveni…

- CHISEL POINT FOR FEWER JAMS – Sturdy staples are constructed to quickly pierce paper with sharp chisel points. Designed …

- SECURES 25 SHEETS OF PAPER – These staples serve a variety of typical fastening needs. With a ¼” leg length, they can ho…

- Value pack includes (10) packs of 5,000 staples (50,000 total staples); ideal for any busy workplace

- Standard size staples compatible with most staplers; durable design efficiently pierces through paper

- Packaged in handy cardboard packs for tidy, convenient containment and for easily distributing throughout the workplace

- 【High-Quality Material】Made from 304 stainless steel, these fence staples are rust and corrosion resistant, designed to …

- 【Easy Installation】No need to pre-drill holes. Easily install or remove fence post screws using an electric drill, allow…

- 【Strong and Secure Hold】Each staple features 2 V-shaped teeth on each side that bite firmly into the wood, holding wire …

- PREMIUM QUALITY – Tests show 75% fewer failed staple jobs than comparable staples. These staples have proven better perf…

- SHARP CHISEL POINT FOR FEWER JAMS – Staples with precision-engineered points are designed to cleanly pierce paper. Disti…

- SECURES 25 SHEETS OF PAPER – These staples serve a variety of fastening needs. With ¼” leg length, they can hold up to 2…

- Finely honed chisel points for maximum penetration

- Superior quality high carbon steel wire reduces buckling and jamming

- Full strip staples – each strip contains 210 staples

- SUPERIOR JAM-FREE STAPLES – Optima Premium Staples provide optimal quality and service. Backed by Swingline’s jam-free g…

- SHARP CHISEL POINT PREVENTS JAMS – Designed with precision-engineered points, Optima staples cleanly pierce paper every …

- SECURES UP TO 25-40 SHEETS – Strong staples serve multiple fastening needs. Their 1/4” length legs hold up to 25 sheets …

A balanced selection of staples is essential for a smooth operation in any setting. Office staples, for instance, are manufactured to be used repeatedly without bending or breaking, ensuring that documents remain securely bound. In contrast, industrial staples are built for strength and durability, capable of withstanding the stresses of heavy-duty use. For those in the construction sector, heavy duty staples provide the extra reliability needed for safety-critical applications. Each type of staple is designed with specific attributes in mind—such as paper staples with precision points or metal staples that offer enhanced grip. Detailed studies indicate that using the right staple type reduces material waste and improves process efficiency (Fastener Info).

Technical specifications of staples vary widely based on their intended application. Many companies now offer staples in different gauges, lengths, and finishes, allowing for precise customization. For instance, paper staples are typically available in sizes that fit standard staplers, while metal staples might be designed for use in heavy machinery. Such diversity in design helps meet the demands of various industries and promotes innovation in fastener technology. Data from recent market surveys reveal that companies that adopt specialized staples often see improved productivity and lower operational costs. This evidence underscores the value of investing in high-quality staples for both office and industrial uses.

Staples are also appreciated for their cost-effectiveness. Despite their small size, staples offer a high return on investment by reducing the need for frequent replacements. For small businesses, reliable staples mean fewer interruptions and smoother document management. In industrial environments, the durability of heavy duty staples ensures that machinery operates without unexpected downtime. The economic benefits extend beyond immediate cost savings, as the use of premium staples can lead to long-term improvements in equipment performance and safety. The correlation between staple quality and operational efficiency is a critical consideration for both manufacturers and consumers.

Advances in staple technology have led to the introduction of features that enhance their usability. For example, some staples now come with anti-jamming designs, ensuring consistent performance even in high-volume settings. Others are designed with a special coating that resists rust and corrosion, making them ideal for outdoor and industrial applications. These innovations not only improve functionality but also extend the lifespan of the staples. Users have noted that staplers equipped with modern staples experience significantly fewer malfunctions, which contributes to a more efficient workflow. Such improvements are a clear indication of how a simple staple can evolve into a high-performance component.

The reliability of staples is further supported by strict industry standards and quality control measures. Manufacturers employ rigorous testing procedures to ensure that every batch of staples meets specific criteria for strength, durability, and safety. Regulatory bodies in various countries set minimum requirements, and many companies exceed these standards to deliver products that are both dependable and long-lasting. This level of quality assurance is essential for customers who rely on staples for critical tasks. In many cases, the investment in premium staples is justified by the increased safety and reduced risk of equipment failure, as highlighted in technical reports from ISO Standards.

Business and industrial settings benefit from the consistent performance of staples in diverse applications. The use of staples extends to areas such as upholstery, packaging, and even bookbinding. Each application demands a particular type of staple, and manufacturers have risen to the challenge by offering a wide range of options. Whether you require office staples for daily paperwork or industrial staples for heavy machinery, the correct choice can enhance overall performance and efficiency. This extensive range of options ensures that every requirement is met, from the smallest office task to the most demanding industrial application.

Staples are also a critical component in modern supply chains. Companies that depend on fasteners often monitor staple usage as a key performance indicator in their operations. Statistics show that even a minor improvement in staple efficiency can result in significant cost savings over time (Supply Chain Quarterly). The role of staples in maintaining smooth operations cannot be overstated, as they directly influence the reliability and productivity of various systems. This makes the selection of high-quality staples a priority for both operational managers and procurement specialists.

The aesthetics and functionality of staples have evolved to meet the needs of modern consumers. In the office environment, staples are designed to be discreet yet highly effective. In contrast, industrial staples often feature robust construction and a utilitarian design that underscores their purpose. Such diversity in design helps users quickly identify the right type of staple for their specific needs. Furthermore, the environmental impact of staple production is increasingly important, with many manufacturers now prioritizing sustainable practices. This commitment to eco-friendly production has earned praise from industry experts and environmentally conscious consumers alike.

Quality control in staple manufacturing is a topic of ongoing research and innovation. Recent advancements in production technology have enabled manufacturers to produce staples with unmatched precision and consistency. Enhanced quality control measures have led to a decrease in defective products and improved overall customer satisfaction. This focus on quality has not only bolstered the reputation of staple manufacturers but has also driven further innovation in the fastener industry. Detailed research indicates that companies investing in advanced manufacturing techniques for staples see a reduction in production waste and enhanced product longevity (Manufacturing Today).

In addition to technical specifications, the usability of staples is paramount for everyday operations. Staples should be easy to load into staplers, compatible with various devices, and reliable under continuous use. User reviews often highlight the satisfaction derived from staples that perform consistently without frequent jams or misfires. Practical considerations such as ease of use and reliability are essential for maintaining a productive workspace. When selecting staples, it is advisable to consider products that have been tested in real-world conditions. Such feedback from users ensures that the chosen staples will meet both performance and practical requirements.

As a final note, the selection of the best staples involves careful research and comparison of product specifications. High-quality office staples and industrial staples are designed to cater to different needs while upholding strict standards of durability and performance. Expert reviews, market statistics, and user testimonials all point to the fact that the right staples can significantly enhance operational efficiency and safety. For anyone in the market for fasteners, this guide serves as a comprehensive resource to navigate the diverse world of staples. Armed with detailed insights and technical data, you can make an informed decision that aligns with your specific needs.

Final Thoughts on Staples: A Fastener Worth Investing In

Staples are more than just a mundane office supply—they are a testament to the evolution of fasteners. Whether you are a business owner seeking reliable office staples or an industrial professional in need of heavy duty staples, choosing the right product can elevate your operational performance. By investing in high-quality staples, you not only secure documents or materials but also invest in long-term efficiency and safety. The technical innovations in staples, from anti-jamming features to corrosion-resistant coatings, are transforming how we approach everyday fastening needs.

The extensive research and testing behind each staple type make them a critical component in various applications. Detailed case studies indicate that using the best staples can reduce maintenance costs and boost productivity by nearly 20% (Industry Today). This information is invaluable for anyone who relies on fasteners for critical operations. With proper usage and periodic assessments, staples can serve as the backbone of efficient workflow management in both small offices and large industrial plants.

Practical tips for choosing the best staples include considering the specific requirements of your stapling device, the environmental conditions in which they will be used, and the expected load or frequency of use. Bullet points to consider:

- Durability: Look for staples with high tensile strength and corrosion resistance.

- Compatibility: Ensure the staple size matches your stapler or application device.

- Eco-Friendliness: Consider products made with recycled materials.

- Cost Efficiency: Evaluate the long-term savings from reduced maintenance needs.

- User Feedback: Check reviews and case studies for real-world performance data.

These guidelines can help you navigate the market and select the perfect staples for your needs. The decision to upgrade to premium staples can result in fewer jams, longer-lasting performance, and an overall boost in productivity. Investing in the right fastener not only safeguards your documents and materials but also reinforces your commitment to quality and efficiency.

Understanding the science behind staple production and usage also provides insight into broader manufacturing trends. Innovations in metallurgy and precision engineering have enabled the production of staples that are both cost-effective and highly durable. This balance of efficiency and quality is a cornerstone of modern fastener design. As industries continue to evolve, the role of staples remains pivotal, ensuring that every document, package, and structural component is securely held together.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”