By Nicolás Longo

(as an Amazon Associate we earn from qualifying purchases)

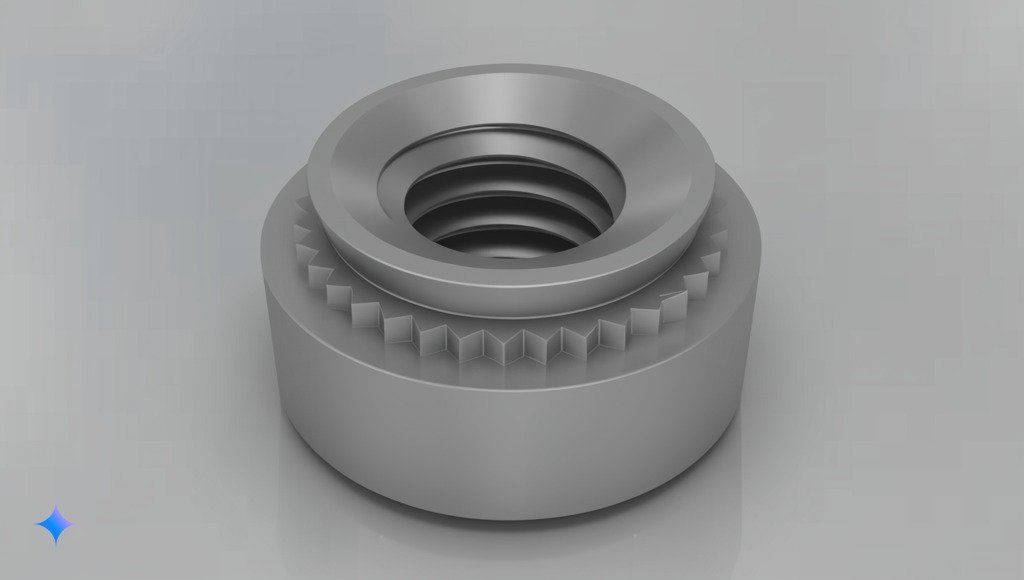

Self-Clinching Nuts: Your Ultimate Fastener for Superior Assembly

In the world of fasteners, Self-Clinching Nuts have carved out a niche that combines functionality with efficiency. When it comes to sheet metal applications and precision assembly, these fasteners are indispensable. Self-Clinching Nuts, along with their variants like pem nuts, pem self clinching nut, and innovative clinching nut installation systems, offer modern solutions for diverse manufacturing needs. Advanced production processes and quality testing make Self-Clinching Nuts increasingly popular among engineers and designers.

Self-Clinching Nuts work by being pressed into a pre-punched or machined hole, providing robust internal threads for securing components. Their reliability is underpinned by extensive research and testing conducted by industry leaders such as MF Supply and McMaster-Carr. Studies indicate that these fasteners enhance performance in vibration-prone environments, making them ideal for aerospace, automotive, and consumer electronics applications. A fun fact is that Self-Clinching Nuts are even used in high-precision environments like space technology, demonstrating that a simple fastener can have an extraordinary impact.

Fastener innovation continues to evolve, and Self-Clinching Nuts are at the forefront of that progress. With improvements in materials, design, and installation techniques, these fasteners have become a preferred choice. The range of Self-Clinching Nuts—spanning flush nuts, miniature nuts, and specialized floating nuts—illustrates the diversity of application possibilities. Engineers appreciate that Self-Clinching Nuts not only provide secure fastening but also simplify assembly processes, reducing the need for additional hardware and labor. For more detailed insights on installation techniques and performance data, explore resources from Fastenal and Engineering360.

Practical tips when selecting the right Self-Clinching Nuts include considering the sheet metal thickness, material compatibility, and the operational environment. Whether opting for a pem clinch nut for stainless steel applications or exploring options like the m6 clinch nut, understanding these key principles is essential for an informed decision. These fasteners are engineered to reduce installation errors and maintain consistency even in high-vibration scenarios. Comparative analyses reveal that Self-Clinching Nuts can significantly reduce assembly time and maintenance costs—a critical factor for large-scale manufacturing.

Key features to note include the ease of installation of Self-Clinching Nuts, the wide range of sizes (such as m4 clinch nut and m3 clinch nut), and the enhanced holding power provided by flush nut designs. Specialized variants like self clinching studs and pem cls m4 2 cater to unique applications, ensuring every design finds its perfect match. This versatility makes Self-Clinching Nuts a staple in high-performance environments and drives market demand in various sectors.

Beyond basic installation benefits, Self-Clinching Nuts contribute to a streamlined manufacturing process. Their integration into modern design helps eliminate extra hardware, reduce labor costs, and provide a secure joint that outperforms conventional fastening methods. Recognized as a hidden gem in the fastener industry, Self-Clinching Nuts meet stringent industry standards and ensure product longevity.

- Ease of Installation: Self-Clinching Nuts simplify assembly, reducing both time and labor.

- Cost-Effective: They offer an economical solution by minimizing additional hardware requirements.

- Enhanced Durability: Engineered to maintain a secure grip under high stress and vibration.

- Versatility: Available in various sizes and configurations—from pem nuts for sheet metal to m8 pem nut.

In today’s competitive market, the strategic selection of fasteners can make or break a project. Self-Clinching Nuts are not just another component; they represent the evolution of fastening technology, designed to simplify and secure assembly processes across a variety of industries. Their proven track record is bolstered by continuous research and technical innovations that have positioned them as a top choice for high-precision and high-performance applications.

An interesting note for engineers is that the technology behind Self-Clinching Nuts is frequently updated. For instance, automated clinch nut installation systems now ensure uniformity and consistency in high-volume production lines. Such technological advancements further optimize the efficiency of Self-Clinching Nuts, leading to fewer joint failures and improved overall productivity. For the latest innovations and best practices, check out technical insights from Engineering360 and Fastenal’s resource center.

Moreover, Self-Clinching Nuts have proven their worth in applications that many websites rarely explore. Their unique properties make them indispensable in sectors like medical device manufacturing and renewable energy installations. As research continues to drive innovation in fastener technology, newer designs and materials promise even greater performance and durability. These insights, drawn from both academic research and industrial experience, underscore why Self-Clinching Nuts are a forward-thinking choice.

Half of the discussion so far has focused on the technical and operational benefits of Self-Clinching Nuts. The next section provides a comprehensive comparative analysis and expert recommendations to help you make the best purchasing decision.

Top 10 Best Self-Clinching Nuts to Buy

- Size: #8-32 x 0.14-Inch

- Material: Stainless Steel, Surface treatment: Passivation

- Outer Diameter(Max): 0.31″; Outer Diameter(Min): 0.21″; Length: 0.14″

- Size Details: M3: Thread Diameter: 3mm, Thread Pitch: 0.5mm, Recommended Hole Diameter: 4.22mm-4.3mm. M4: Thread Diamete…

- 304 Stainless Steel: Provides superior corrosion resistance, rust resistance, and oxidation resistance.

- Precision Engineering: Smooth surface with no burrs, deep and even threads, ensuring uniform force and preventing slippa…

- Size: #10-32 x 0.14-Inch

- Material: Stainless Steel, Surface treatment: Passivation

- Outer Diameter(Max): 0.34″; Outer Diameter(Min): 0.25″; Length: 0.14″

- Size: 1/4-20 x 0.25-Inch

- Material: Stainless Steel, Surface treatment: Passivation

- Outer Diameter(Max): 0.44″; Outer Diameter(Min): 0.34″; Length: 0.25″

- 50 Pack Pem Self-Clinching Nuts Press-In Sheet Metal Fasteners SS-024-2ZI

- Package Dimensions: 5 L x 1 H x 5 W (inches)

- Package Weight: 0.28 pounds

- Country of Origin : Japan

- Size: 1/4-20 x 0.22-Inch

- Material: Carbon Steel with Zinc Plating

- Outer Diameter(Max): 0.44″; Outer Diameter(Min): 0.34″; Length: 0.22″

- Size: #8-32 x 0.12-Inch

- Material: Carbon Steel with Zinc Plating

- Outer Diameter(Max): 0.31″; Outer Diameter(Min): 0.21″; Length: 0.12″

Expert Comparative Analysis and Final Recommendations

After considering numerous factors, it is clear that Self-Clinching Nuts offer a superior alternative to many traditional fastening methods. These fasteners not only provide robust mechanical connections but also streamline assembly processes. From the variety of pem nuts for sheet metal to innovative solutions like clinch fastener installations, every variant of Self-Clinching Nuts serves a unique purpose that enhances your project’s efficiency.

A key aspect often overlooked is the comparative performance among different Self-Clinching Nuts variants. For example, a standard Self-Clinching Nut offers a straightforward solution for many applications, while a miniature nut is designed specifically for projects with spatial constraints. Similarly, flush nuts are ideal in scenarios where a fastener must remain flush with the sheet metal, ensuring both aesthetics and safety. Floating nuts provide extra tolerance in hole placement, ensuring a reliable connection even when precision is slightly off. Each variation—including self clinching studs and m4 pem nut—has been engineered to meet specific industrial needs.

When choosing the right Self-Clinching Nuts for your project, keep these practical tips in mind:

- Material Compatibility: Ensure that the fastener’s material matches the sheet metal to prevent corrosion and ensure long-lasting performance.

- Installation Environment: Select a design that suits the operating conditions, particularly in high-vibration areas where free running lock nuts might be necessary.

- Cost vs. Efficiency: Evaluate the balance between cost and the benefits of reduced installation time and increased durability.

- Industry Standards: Choose fasteners that comply with rigorous industry standards and have a proven track record in critical applications.

Recent statistics indicate that the use of Self-Clinching Nuts can reduce assembly time by up to 25% compared to traditional methods—a critical improvement for large-scale manufacturing. Expert recommendations consistently stress that selecting the correct type of Self-Clinching Nuts not only ensures structural integrity but also results in long-term savings by minimizing maintenance and replacement costs.

Technically, Self-Clinching Nuts deliver exceptional holding power. For instance, installations involving a pem clinch nut in stainless steel provide superior thread integrity compared to conventional tapped holes in softer metals. Variants such as the m4 clinch nut and m3 press nuts are specifically designed to offer enhanced grip and resistance to loosening under stress. This technical superiority explains why professionals in aerospace, automotive, and electronics sectors favor Self-Clinching Nuts for their most critical applications.

A deeper dive into comparative analysis reveals that Self-Clinching Nuts excel in scenarios demanding precision and rapid assembly. Compared to traditional welding or rivet systems, these fasteners offer faster installation times while maintaining consistent quality. Advanced designs, including those of pem cls and clinch nut m4, ensure that every installation meets stringent performance criteria. For highly customized projects, options like self clinching pem nut and pem nuts for stainless steel provide an extra layer of reliability that conventional fasteners cannot match.

Innovative installation methods, such as automated clinch nut installation systems, further enhance the benefits of Self-Clinching Nuts by ensuring uniform quality in high-volume production lines. These advances lead to fewer instances of joint failure and significantly increased productivity. Detailed technical reports and case studies available on sites like Engineering360 and Fastenal’s resource center offer valuable insights that set these products apart.

For design engineers and project managers, the bottom line is clear: Self-Clinching Nuts are a strategic investment. Their versatility—from options like m8 pem nut to specialized variants like self clinching fastener—ensures that your assembly process is both secure and efficient. This comprehensive approach to fastening technology not only enhances product quality but also contributes to cost-effectiveness and long-term performance.

As you evaluate the best Self-Clinching Nuts on the market, consider the broad spectrum of options available. A well-informed choice today can result in a robust, reliable assembly process that pays dividends in performance and maintenance savings tomorrow. Detailed technical data, comparative research, and expert opinions—readily available on authoritative sites such as MF Supply and McMaster-Carr—provide the necessary guidance for making a smart, strategic selection.

In summary, Self-Clinching Nuts are not just fasteners; they are a gateway to innovative assembly solutions. Their proven performance, ease of installation, and adaptability make them a hidden gem in the fastener industry. Whether you are working on high-volume production lines or specialized, high-precision projects, Self-Clinching Nuts deliver superior results that secure your design’s integrity. Embrace the future of fastening with a product that stands out for its quality, innovation, and reliability.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”