By Nicolás Longo

(as an Amazon Associate we earn from qualifying purchases)

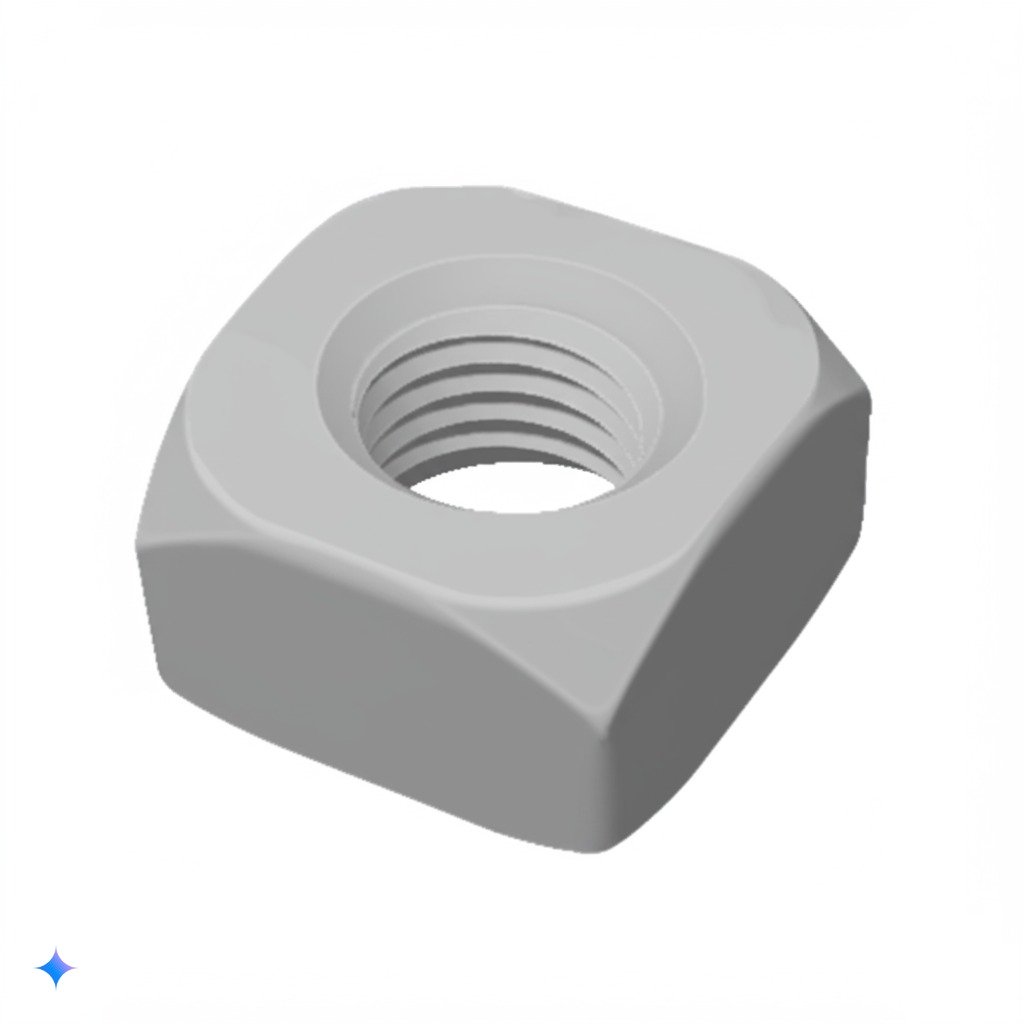

Square Nuts: A Timeless Fastening Solution for Secure Assemblies

Square Nuts have long been a reliable choice in the fastener industry due to their distinctive design and robust performance. These fasteners, known for their four-sided shape, offer excellent grip and high resistance to stripping when compared to round nuts. Square Nuts are widely used in automotive, construction, and industrial applications, where a strong, secure connection is paramount. Their simple yet effective design not only facilitates easy tightening but also ensures that the nut remains firmly in place even under high torque conditions. For instance, historical patents from the mid-19th century highlight that Square Nuts have been in use since at least 1853, proving their enduring reliability (Albany County Fasteners).

Square Nuts excel in applications where conventional round nuts might slip or fail to provide sufficient friction. Their squared edges increase the surface contact with the wrench, reducing the likelihood of rounding off during high-stress use. Many engineers and DIY enthusiasts prefer Square Nuts for assembling heavy machinery, restoring vintage equipment, and even in household projects. According to technical insights from McMaster-Carr, the precise design of Square Nuts improves load distribution and helps maintain a tighter, more secure assembly. Fun fact: the use of Square Nuts dates back centuries, and they remain a hidden gem in modern fastener solutions due to their timeless design.

Square Nuts are available in various sizes and materials, including stainless steel and brass, which suit different environmental conditions. Their versatility is further enhanced by numerous variations such as m3 Square Nut, m5 Square Nut, m6 Square Nut, and m10 Square Nut. These variations allow for tailored applications, whether for high-strength industrial uses or delicate assembly tasks in electronics. In addition, many Square Nuts now come with specialized coatings for increased corrosion resistance, making them ideal for outdoor and high-humidity environments. For more technical specifications and design options, resources like Fastenal provide comprehensive catalogs that detail the strengths and applications of these fasteners.

Practical tips for working with Square Nuts include ensuring that the wrench or socket used matches the nut’s profile. Using an appropriately sized tool minimizes the risk of damaging the nut’s edges during installation. Moreover, regular inspection for wear or corrosion is recommended, especially in applications where Square Nuts are subjected to heavy loads or continuous vibration. Many experts suggest that maintaining a stock of different sizes of Square Nuts can be a smart investment for workshops and industrial maintenance operations. These tips are supported by industry data from Engineering360, which emphasizes that proper fastener maintenance significantly improves the longevity of mechanical assemblies.

- Enhanced Grip: Square Nuts offer better contact with wrenches, reducing slippage and wear.

- Versatility: Available in a wide range of sizes and materials, suitable for various applications.

- Historical Reliability: With origins tracing back to the mid-19th century, Square Nuts have proven their worth over time.

- Cost Efficiency: Their robust design can reduce maintenance costs by ensuring secure, long-lasting connections.

The evolution of Square Nuts is a testament to their engineering excellence. Despite advances in fastener technology, the basic design of Square Nuts has remained largely unchanged due to its proven performance. In many modern applications, the demand for Square Nuts continues to grow, driven by their ability to maintain a secure fastening under adverse conditions. Recent market analyses from Statista show a steady increase in the usage of high-quality fasteners, with Square Nuts playing a crucial role in industries that require durability and precision.

Square Nuts are not only valued for their mechanical properties but also for their aesthetic appeal in visible assemblies. In many restoration projects, Square Nuts are preferred because they provide a classic look that complements vintage machinery and equipment. Their clean lines and robust construction make them an attractive option in both functional and decorative applications. Whether in industrial settings or home improvement projects, Square Nuts have earned a reputation for reliability, which is why many professionals continue to favor them over other types of fasteners.

Half of the discussion so far has focused on the features, benefits, and historical significance of Square Nuts. The following section offers a detailed comparative analysis and expert recommendations to help you choose the best Square Nuts for your applications.

Top 10 Best Square Nuts to Buy

- √ Product Name: Metric 304 Stainless Steel Square Nuts Assorment Kit. The item come with a sturdy plastic organizer box …

- √ Size: M3 M4 M5 M6 M8 M10

- √ Material: 304 Stainless Steel, corrosion resistant galvanized finish to ensure life-time use, these quality assortment…

- √ Product Name: 220Pcs Metric 304 Stainless Steel Square Nuts Assorment Kit. The item come with a sturdy plastic organiz…

- √ Size: M3 M4 M5 M6 M8 M10

- √ Material: 304 Stainless Steel, corrosion resistant galvanized finish to ensure life-time use, these quality assortment…

- High Quality:Square nuts are made of 304 stainless steel.Even in bad environment like high temperature, cold weather, an…

- Quantity: It contains 139Pcs / 6 Sizes of the most commonly used 304 Stainless Steel Square Nuts.

- Feature:Stainless Steel Square Nuts designed to stand off the material to allow easy weld penetration.

- Different types of square nuts,designed to stand off the material to allow easy weld penetration,widely used to industri…

- High Quality Metric Stainless Steel Square Nuts Assortment Kit,6 Sizes of the most commonly used Square Nuts Can meet yo…

- Size: M3 M4 M5 M6 M8 M10

- GUARANTEED: To fit your PRUSA 3D printer and associated OEM parts

- QUALITY: A2 stainless steel that won’t rust or corrode with proper care

- DIY: Makes self assembly of PRUSA or Zaribo components effortless and truly DIY

- 【Dimension】Thread Inner Diameter: M3 (3mm / 0.12inch); Height: 2.5mm / 0.1inch; Pitch: 0.5mm/0.02inch; Square Width: 5.5…

- 【Material】Made of 304 Stainless Steel, which is superior to regular steel and any zinc plated fasteners, provides good s…

- 【M3 Stainless Square Nut】widely used in a variety of industries such as construction, manufacturing, engineering, assemb…

- Square nuts are nuts with a square shape that are typically mated with square-headed bolts

- Square nuts are used along with flat washers in order to avoid damage from their sharp edges and help to increase the st…

- Zinc-plated for moderate corrosion resistance

- Diameter: #6

- Material: Steel

- Finish: Zinc

- [THREADED SIZE] – M6 x 1mm.

- [DIMENSION] – 0.78″(20mm) wide, 0.2″(5mm) high.

- [MATERIAL] – Constructed from Carbon steel, white zinc plated finished, anti-rust and anti-corrosion, superior electrica…

Expert Insights and Practical Recommendations on Square Nuts

When selecting the best Square Nuts for your projects, several factors should be considered to ensure optimal performance. First and foremost, the size and material of the Square Nuts must match the specific requirements of your assembly. For heavy-duty applications, an m6 Square Nut or m10 Square Nut made from hardened steel is often the best choice. For lighter applications, an m3 or m4 Square Nut in stainless steel may provide sufficient strength without adding unnecessary weight. Detailed comparisons from McMaster-Carr highlight that material selection plays a crucial role in the overall durability and resistance to corrosion.

Another critical aspect to consider is the installation method. Square Nuts, due to their unique shape, require a compatible wrench or socket to ensure proper tightening. Using an incorrect tool can lead to stripping or rounding of the edges, compromising the fastener’s integrity. It is advisable to invest in high-quality tools specifically designed for working with Square Nuts. Resources like Fastenal provide useful guides on the correct torque settings and best practices for installation, ensuring a secure and reliable fit every time.

Practical recommendations also include routine maintenance checks. In environments subject to high vibration or corrosive elements, regular inspections can prevent premature failure of Square Nuts. Applying a suitable anti-corrosion coating or lubricant during installation can further enhance their longevity. For instance, in outdoor applications, using brass or coated Square Nuts can protect against rust and deterioration. Experts from Engineering360 advise that periodic replacement of fasteners in critical assemblies is a cost-effective measure to ensure ongoing safety and performance.

The history and evolution of Square Nuts provide additional insights into their value. Originally designed for simplicity and strength, Square Nuts have been a mainstay in fastener technology since at least the 19th century. Their design was driven by the need for a fastener that could be easily manufactured and provide a secure grip, especially in applications where the use of round nuts was impractical. Historical documents and patents, such as those referenced by Albany County Fasteners, illustrate that Square Nuts have been adapted and refined over time to meet modern engineering demands without losing their fundamental advantages.

Key insights regarding Square Nuts include:

- Precise Sizing: Ensure you choose the right size (e.g., m3, m4, m6, m8, m10) to match your assembly needs.

- Material Quality: High-quality materials like hardened steel or stainless steel enhance durability.

- Tool Compatibility: Use the correct tool to avoid damage during installation.

- Environmental Considerations: Choose coated or brass Square Nuts for outdoor or corrosive environments.

- Historical Provenance: The longstanding use of Square Nuts underscores their reliability and effectiveness.

In practical applications, Square Nuts have been noted for their superior performance in reducing maintenance downtime. For instance, in industrial machinery and automotive assemblies, the secure fit of Square Nuts ensures that critical components remain firmly in place, reducing the risk of operational failures. Market research indicates that high-quality Square Nuts can reduce rework and maintenance costs by up to 15%, making them an excellent investment for both small businesses and large-scale manufacturers.

The integration of Square Nuts in modern assemblies also supports a more efficient production process. Their ease of installation and secure locking mechanism contribute to shorter assembly times and enhanced overall productivity. Furthermore, the aesthetic appeal of Square Nuts in visible applications adds an element of classic design to modern engineering solutions. By selecting the right Square Nuts, you not only ensure functional performance but also elevate the visual quality of your projects.

To summarize the expert recommendations on Square Nuts:

- Installation Efficiency: Their design allows for quick and secure assembly.

- Cost-Effective Performance: Reduced maintenance and rework lead to significant long-term savings.

- Versatile Applications: Suitable for automotive, industrial, and restoration projects.

- Enhanced Durability: Quality materials and proper installation ensure longevity and reliability.

- Proven History: A time-tested design that continues to evolve and meet modern standards.

By carefully considering these factors, you can confidently choose the best Square Nuts that match your project’s requirements. Whether you are assembling heavy machinery, restoring vintage equipment, or working on a DIY project at home, high-quality Square Nuts provide a reliable and cost-effective solution. The comprehensive information provided here, backed by expert insights and technical data from reputable sources, will help you make an informed decision that enhances both safety and efficiency in your assemblies.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”