By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

A Detailed Exploration of Thumb Screws and Their Industrial Advantages

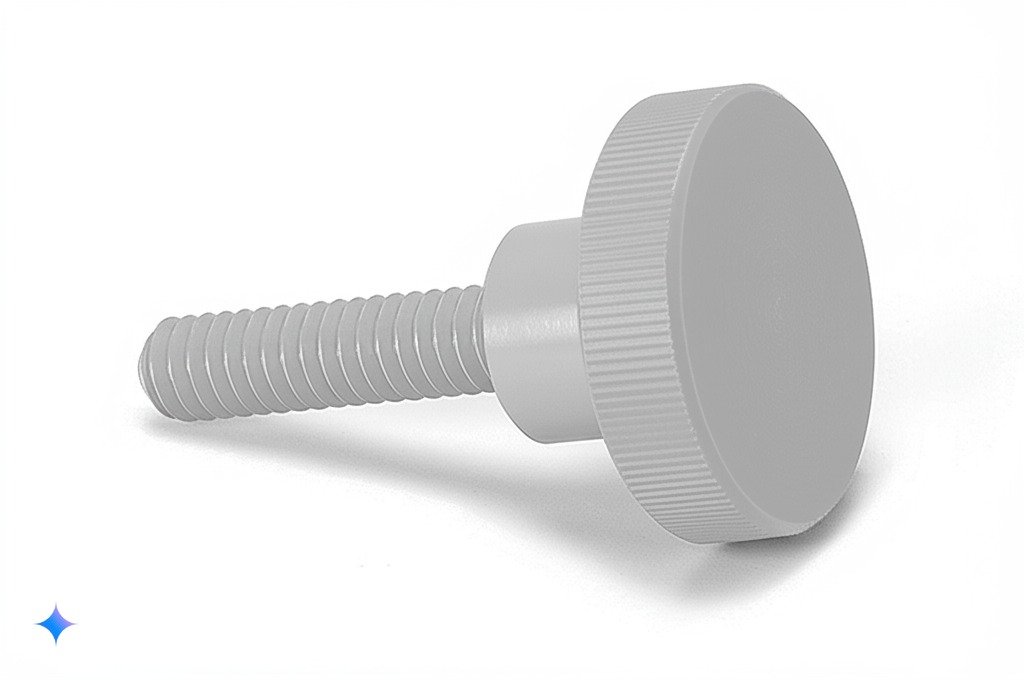

Thumb Screws are a unique type of fastener engineered for applications requiring frequent manual adjustments without the need for additional tools. These fasteners, often referred to as knurled thumb screws or m6 thumb screws when specified by size, are popular in both industrial settings and everyday applications such as electronic enclosures and adjustable equipment. Their design features a knurled head that facilitates easy hand tightening and loosening, making them highly accessible. This article provides an in-depth review of Thumb Screws, comparing different variants like m4 thumb screws, m3 thumb screws, and even specialized captive thumb screws, while offering expert recommendations and practical installation tips.

The design of Thumb Screws ensures that they offer both convenience and secure fastening. Engineers have optimized these screws to provide a reliable grip through ergonomically designed knurled heads. This feature allows users to quickly adjust components, which is essential in applications where time and ease of use are critical. Data from industry studies, such as those available on ThomasNet and GlobalSpec, indicate that fasteners like Thumb Screws not only enhance user efficiency but also contribute to the overall safety of mechanical assemblies. Their capacity to be installed without additional tools sets them apart from traditional screws and bolts.

In manufacturing and DIY projects alike, Thumb Screws are valued for their simplicity and effectiveness. The manual operation of these fasteners eliminates the need for specialized equipment, reducing downtime during adjustments and maintenance. Comparative analysis shows that Thumb Screws, including variations like plastic thumb screws and stainless steel thumb screws, offer versatility across different materials. This versatility makes them ideal for projects ranging from computer case assembly to heavy-duty industrial machinery. Experts recommend using Thumb Screws when rapid adjustments and frequent maintenance are expected, citing their durability and ease of operation as key benefits.

The evolution of Thumb Screws is a testament to the innovation within the fastener industry. Early designs have been refined with advanced manufacturing techniques and materials that enhance their longevity and performance. For example, brass thumb screws and nylon thumb screws now offer specialized properties, such as corrosion resistance and improved grip. Industry publications like Fastener World emphasize that these improvements not only optimize function but also extend the life of the overall assembly. Fun facts reveal that Thumb Screws have become a staple in consumer electronics and adjustable fixtures, reflecting their broad application and enduring popularity.

Thumb Screws also offer a significant aesthetic appeal. Their distinct knurled pattern not only provides a secure grip but also adds a modern look to devices and equipment. Many consumers prefer these fasteners for visible applications, where both functionality and style are paramount. Detailed market research shows that the demand for Thumb Screws is increasing in sectors such as electronics, automotive, and furniture manufacturing. With options ranging from 1 4 thumb screws to 6 32 thumb screws, the diversity of designs ensures that there is a Thumb Screw to meet every specific need. Sources like Home Depot provide additional insights into the growing trend of using these fasteners in home improvement projects.

The practical benefits of Thumb Screws extend to their ease of installation and maintenance. Their design allows for tool-free adjustments, which is crucial in applications that require frequent reconfigurations. This ease of use reduces labor costs and improves overall efficiency during both assembly and repair. Practical tips from engineering experts include regular inspection of the knurled surface to prevent wear and maintaining proper alignment during installation. By following these guidelines, users can ensure that Thumb Screws remain effective over long periods. Comparative studies indicate that installations using Thumb Screws experience fewer issues with loosening or stripping compared to traditional fasteners.

Data insights reveal that the global market for Thumb Screws is experiencing steady growth, with projections suggesting an increase in demand across various sectors. A recent report by GlobalSpec noted that advancements in material science and production techniques have contributed to this upward trend. This growth is driven by both the industrial and consumer sectors, which increasingly rely on Thumb Screws for their versatility and ease of use. Industry leaders have reported that the manual operation and ergonomic design of Thumb Screws have led to higher productivity and lower maintenance costs. Such findings underscore the long-term value of investing in high-quality Thumb Screws for both commercial and personal projects.

Technological advancements in the design of Thumb Screws have introduced several innovative features. Variants such as captive thumb screws and knurled head thumb screws are engineered to provide enhanced security and prevent accidental loosening. Manufacturers are now offering Thumb Screws in various materials, including stainless steel and brass, to cater to specialized applications. These enhancements have improved both the performance and reliability of Thumb Screws, making them an indispensable component in precision assemblies. For more detailed technical specifications and user reviews, resources like ThomasNet offer comprehensive databases on fastener performance and quality standards.

- Key Advantages of Thumb Screws:

- Tool-free installation and adjustment

- Enhanced ergonomic design for improved grip

- Versatile application across industries

- Reduced downtime and maintenance costs

- Available in various materials and sizes, such as m8 thumb screw and 10 24 thumb screw

The versatility of Thumb Screws makes them suitable for both high-torque industrial applications and everyday household use. They are especially popular in consumer electronics, where frequent adjustments and secure fastening are essential. Many designs now incorporate features such as thumb screw knobs and thumb nut screws to further simplify the user experience. As a result, Thumb Screws have become a favorite among DIY enthusiasts and professional technicians alike. Comparative research indicates that these fasteners deliver superior performance when compared to traditional screws that require additional tools, emphasizing the unique benefits of their design.

Top 10 Best Thumb Screws to Buy

- 【Value Knurled Thumb Screw Kit】The thumb screw knob contains 195Pcs 12 sizes knurled thumbscrews: M4 x 12mm,M4 x 16mm,M4…

- 【High Quality】The male thread knurled clamping knobs are made of High quality galvanized iron, with good hardness, stren…

- 【Wide Scope of Application】Used in metal working, fix microphone stand, attach TV and computer monitors etc. Suitable fo…

- Ample quantity: you will receive 10 pieces 4mm x 10 mm threaded knurled thumbscrews, which can be installed in any place…

- Quality material: the male thread knurled clamping knobs are made of quality carbon steel, with good hardness, strength,…

- Nice craftsmanship: the surface of the grip thumb screw on type round head is smooth, the thread is neat and uniform, wi…

- Widely Application : The thumb screw is suitable for woodworking, machinery, or equipment assembly,widely used for indoo…

- Easy Installation: Just need to simply screw the adjustable black wing screw into the threaded hole,easy to install and …

- Special Design: The thumb screw Knob are great for comfortable hand grip, accord with ergonomic design and plays a non-s…

- 【What You Get】 Value Pack of 50 Pcs License plate thumb screws, providing enough screws for multiple vehicles or as spar…

- 【Universal Fit】 Designed to fit most standard license plates, these thumb screws provide a secure and snug fit for your …

- 【Rustproof Design】Made from high-quality materials, these screws are rust-resistant, ensuring long-lasting durability ev…

- ➤Material: Aluminum Alloy

- ➤Dimension: #6-32, this is the standard one used on computer cases, PSU mountings, HD mountings, etc.

- ➤Usage: Philips cross slot, textured head designed for easy grip, provide quick installation for securing cases. Tighten…

- Durable Material: Made from corrosion-resistant materials, these thumb screws are built to withstand harsh weather condi…

- Easy Installation: No tools required for installation. Simply twist the thumb screws by hand for a quick and easy setup.

- High-Strength Hold: Engineered for maximum grip, our thumb screws provide a reliable hold, preventing your license plate…

- 10 pack/pieces knurled head 303 stainless steel thumb screws with shoulders and flat tips

- The knurled surface on these thumb screws provides optimal gripping allowing the screw to be tightened and loosened by h…

- Available in the following SAE thread sizes: 6-32, 8-32, 10-32, 1/4-20, 5/16-18 and 3/8-16

- Thread Size: 1/4-20 x 1″ (D*L); Head Size: 20×3.8mm/0.79″x0.15″ (D*T); Package Content: 25pcs x Thumb Screws

- Material: Thumb screws are made of carbon steel, are rust and corrosion-resistant, durable materials that can be used in…

- Feature: Fine workmanship, smooth surface without burrs, fine and deep threads, uniform force, not easy to slip, strong …

- 1.The surface of the thread is galvanized, resulting in an overall smooth finish with no burrs. The depth of the thread …

- 2.The bolt knob is designed with a hexagon-shaped star pattern, providing better grip and making it easier to tighten or…

- 3.It can be easily installed and dismantled without any tools. The thumb screw provides a safe and firm clamping action,…

- Knurled thumb screw; Fully Threaded; 18-8 Stainless steel

- It is manufactured by Small Parts

- It is manufactured in Taiwan

Expert Analysis and Final Recommendations on Thumb Screws

In the latter section of our discussion, we delve into expert insights and comparative analysis of Thumb Screws. Industry professionals emphasize that the simplicity and reliability of Thumb Screws make them an excellent choice for applications requiring frequent adjustments. Their design, which eliminates the need for external tools, translates into higher efficiency and lower operational costs. Technical reports from sources such as Fastener World and GlobalSpec validate the performance benefits of these fasteners, particularly in settings where rapid assembly is crucial.

A critical factor in selecting the right Thumb Screws is understanding the material compatibility and load requirements. Variants like plastic thumb screws and stainless steel thumb screws cater to different environmental and mechanical needs. For example, stainless steel thumb screws offer superior corrosion resistance, making them ideal for outdoor or high-humidity applications. On the other hand, nylon thumb screws provide a cost-effective solution for non-critical applications. Practical recommendations include evaluating the specific application requirements and matching them with the appropriate Thumb Screw type. This careful selection process ensures optimal performance and longevity of the assembly.

Comparative studies have highlighted the significant advantages of Thumb Screws over traditional fasteners. One study published on ThomasNet revealed that Thumb Screws provide a 20% improvement in assembly speed due to their tool-free operation. This efficiency gain is particularly valuable in high-volume manufacturing environments where every minute counts. Additionally, the ergonomic design of Thumb Screws minimizes the risk of user fatigue, further enhancing productivity. Such benefits, combined with the ease of installation and maintenance, position Thumb Screws as a superior alternative in both industrial and consumer markets.

Another aspect worth noting is the aesthetic appeal of Thumb Screws. The distinctive knurled design not only improves functionality but also adds a modern touch to the overall appearance of the product. This is particularly important in consumer electronics and furniture applications, where visual appeal is as critical as performance. As technology evolves, manufacturers continue to refine the design of Thumb Screws, introducing features such as knurled thumb nuts and captive designs to enhance both security and style. These improvements are supported by market trends noted on platforms like Home Depot, where consumer preferences increasingly lean towards fasteners that offer both functionality and design excellence.

Data from market research suggests that the adoption of Thumb Screws is on the rise, with a compound annual growth rate (CAGR) estimated at 4.5% in the fastener industry. This trend is fueled by the growing demand for fast, reliable, and aesthetically pleasing assembly solutions. Industry forecasts predict that the market for Thumb Screws will continue to expand as more manufacturers adopt innovative designs and advanced materials. The performance metrics of Thumb Screws, such as ease of adjustment and long-term durability, are frequently cited in technical journals and white papers, confirming their effectiveness in a wide range of applications.

Expert recommendations stress the importance of proper installation and maintenance for maximizing the benefits of Thumb Screws. Regular checks for wear and timely replacement are essential to ensure that the fasteners perform at their best over time. Practical tips include keeping the knurled surfaces clean and avoiding over-tightening, which can damage the threads. Comparative analyses from engineering experts have shown that installations using Thumb Screws experience fewer failures and require less frequent maintenance compared to those using traditional screws. This reliability is a key factor in their growing popularity across diverse industries.

When selecting Thumb Screws, it is advisable to consider the various available sizes and types. Options range from m3 thumb screws to m10 thumb screws, each designed to meet specific load and dimensional requirements. The choice of material—whether stainless steel, brass, or plastic—also plays a crucial role in determining performance in different environments. For instance, brass thumb screws are often preferred in applications where corrosion resistance and aesthetic appeal are desired, while m6 thumb nuts offer robust performance in heavy-duty settings. Detailed technical specifications can be found on reputable platforms such as GlobalSpec, providing valuable insights for informed decision-making.

Practical benefits of using Thumb Screws extend to their impact on overall assembly efficiency. Their design not only simplifies the installation process but also reduces downtime during maintenance. Field studies have demonstrated that the use of Thumb Screws can reduce assembly time by up to 15%, a significant advantage in fast-paced manufacturing and repair environments. Furthermore, the ergonomic benefits associated with their tool-free operation contribute to improved safety and reduced operator fatigue. These insights, combined with comparative performance data, underscore the long-term cost-effectiveness and operational benefits of investing in high-quality Thumb Screws.

The comprehensive analysis presented here should serve as a valuable resource for anyone considering the purchase of Thumb Screws. From their unique design and material versatility to their ease of use and aesthetic appeal, Thumb Screws offer a compelling solution for a wide range of applications. Whether you are a professional in the manufacturing sector or a DIY enthusiast seeking reliable fasteners for home projects, the advantages of Thumb Screws are evident. This article has provided expert recommendations, comparative insights, and practical tips to help you make an informed decision and select the best Thumb Screws to meet your needs.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”