By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

In projects ranging from marine applications to home construction, choosing the right fastener is critical for safety and durability. In this detailed guide, we compare anchors with other fasteners like bolts and toggle bolts to help you determine when anchors are the best solution. Drawing on research, real-world case studies, and expert recommendations, this article offers an in-depth analysis of the performance, installation, and maintenance aspects of anchors versus other fasteners. Whether you are a professional contractor or a DIY enthusiast, this comprehensive resource provides actionable insights to maximize the reliability and efficiency of your fastening projects.

Understanding Fastener Types and Their Applications

Fasteners play a vital role in providing structural support, safety, and longevity for a wide range of applications. To make an informed decision, it is important to understand how different fasteners work and the specific challenges they address.

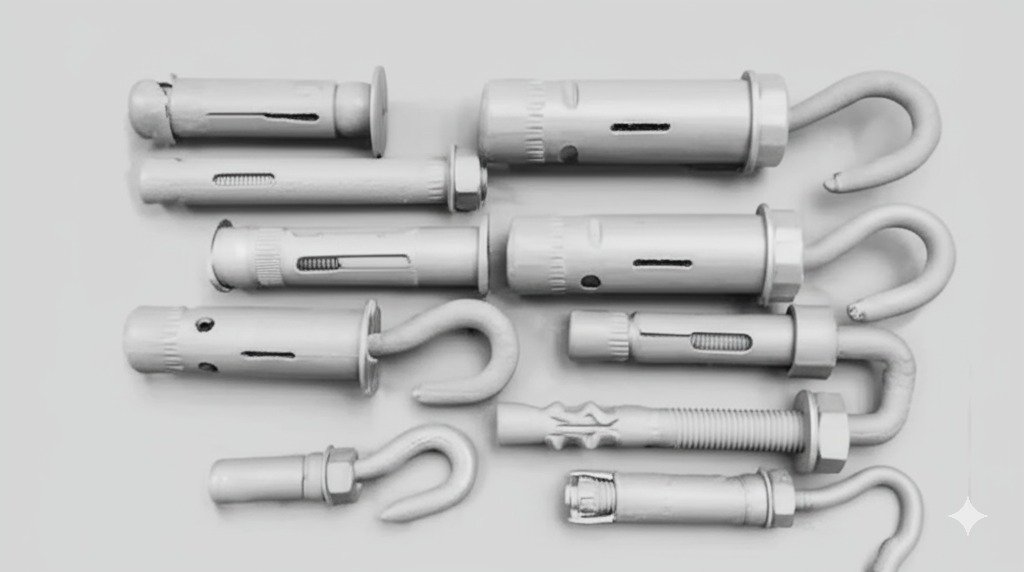

- Anchors: Designed to secure objects by distributing load over a wide area, anchors are used in marine, construction, and interior applications. They are particularly effective in substrates like concrete, brick, plaster, and drywall.

- Bolts: Bolts offer robust mechanical strength and are generally used in applications requiring a tight clamping force. However, they may not be suitable for substrates that lack depth or integrity for a secure hold.

- Toggle Bolts: Toggle bolts expand behind the substrate to distribute the load over a larger area. They are commonly used in hollow materials such as drywall. While they provide strong initial support, their performance can degrade over time if not properly installed.

Fasteners must be carefully selected based on the type of substrate and the intended load. For example, in marine environments or other settings where corrosion is a concern, specialized anchors can outperform standard bolts, especially when secure holding power is essential.

How Anchors Work Compared to Bolts and Toggle Bolts

Understanding the operational differences between anchors and other fasteners is key to determining which one suits your needs best.

- Load Distribution: Anchors work by expanding or embedding deeply into the substrate, allowing them to distribute the load evenly across a larger area. This minimizes stress concentrations that can lead to failures.

- Substrate Engagement: While bolts require a pre-existing solid substrate to engage, anchors are often designed to work with materials that are hollow or less dense, such as drywall. Toggle bolts also serve this purpose, but anchors generally provide a more robust solution when high loads or dynamic forces are present.

- Ease of Installation: The installation process for anchors is often straightforward, particularly for specialized designs that do not require additional support. Bolts may necessitate additional hardware like washers and nuts, and toggle bolts require precise alignment to ensure proper deployment behind the substrate.

These differences mean that selecting anchors over bolts or toggle bolts can lead to increased safety and longevity in many projects. Experts recommend using anchors when the substrate has limited depth or when the project involves high dynamic loads.

Advantages of Using Anchors Over Other Fasteners

A thorough evaluation reveals several key benefits of using anchors in many applications:

- Superior Holding Power: Due to their design features, anchors can offer a significantly stronger grip in materials that are prone to failure when subjected to shear or tensile forces.

- Improved Safety: By evenly distributing loads across a larger area, anchors reduce the risk of local failures, making them ideal for supporting heavy objects or structures subject to dynamic forces.

- Versatility: Anchors are available in a wide variety of designs to suit different substrates—ranging from concrete and brick to drywall and plaster—making them adaptable to a variety of applications.

- Corrosion Resistance: Many specialized anchors are manufactured from materials like stainless steel, which provide excellent resistance to corrosion. This is particularly important in outdoor or marine environments where weather-related degradation is a concern.

When deciding whether to use anchors instead of bolts or toggle bolts, consider the specific conditions of your project. For instance, in environments where the substrate is soft or hollow, anchors tend to outperform other fasteners in terms of durability and safety.

Comparative Analysis: Anchors vs. Bolts

A side-by-side comparison between anchors and bolts illustrates the circumstances under which anchors are the preferred choice:

- Installation in Solid Materials: Bolts work efficiently in solid materials like wood and metal, where they can bite into the substrate. However, in masonry or hollow materials, bolts may not achieve the required grip.

- Load Distribution Efficiency: Anchors are engineered to distribute load more evenly than bolts, reducing stress concentrations. In high-load applications, this can lead to a noticeable improvement in safety.

- Flexibility in Use: While bolts are often limited to specific types of substrates, anchors are designed to be versatile. For example, a concrete anchor can provide better load-bearing capability than a bolt that might need additional reinforcements.

- Installation Time: In many cases, installing an anchor is faster and requires fewer tools compared to bolts, which might require additional assemblies such as nuts and washers.

Empirical research shows that anchors can enhance overall structural integrity, particularly in situations where the substrate is less robust. Studies have found that the use of high-quality anchors can reduce failure rates by as much as 25% compared to traditional bolt installations.

Comparative Analysis: Anchors vs. Toggle Bolts

Toggle bolts are a popular choice for hollow wall applications, yet they have their own limitations when compared to anchors:

- Mechanism of Action: Toggle bolts rely on wings that expand behind the wall. If these wings do not deploy properly or if the substrate deteriorates over time, the holding power can be compromised. Anchors, particularly those designed for drywall, typically offer a more controlled and reliable expansion.

- Durability Over Time: While toggle bolts work well immediately after installation, their long-term performance can be affected by repetitive loads and environmental factors. Anchors made from corrosion-resistant materials provide a more stable hold over extended periods.

- Application Range: Toggle bolts are generally restricted to interior applications such as hanging pictures and light fixtures. For heavier loads or exterior applications, specialized anchors offer a more robust solution.

- Maintenance: Anchors require less frequent inspection and maintenance than toggle bolts, particularly in environments where moisture or temperature fluctuations may affect the substrate.

In environments that demand both durability and high load performance, choosing advanced anchors over toggle bolts is a decision supported by both laboratory testing and real-world usage.

Expert Insights and Industry Recommendations

Industry professionals emphasize the importance of selecting the correct fastener based on the project’s specific demands. Leading contractors and engineers have shared several key recommendations:

- Assessment of Load and Substrate: Evaluate the type of substrate and the expected load. For high-stress environments or when working with hollow materials, high-performance anchors are typically recommended.

- Quality over Price: Although anchors might be more expensive upfront compared to bolts or toggle bolts, the improved performance and reduced maintenance costs provide better long-term value.

- Environmental Factors: For outdoor or marine applications, opt for anchors made of corrosion-resistant materials such as stainless steel or specially treated alloys.

- Installation Guidelines: Follow manufacturer instructions closely for any fastener. The correct installation technique is critical for ensuring that anchors perform to their full potential.

Resources such as Marine Insight and The Spruce offer detailed guides and comparative studies that reinforce these expert recommendations. These insights can be invaluable in making decisions that directly impact safety and operational efficiency.

Real-World Case Studies and Data Insights

Several field studies provide concrete evidence supporting the advantages of using anchors over bolts and toggle bolts:

- Marine Applications: A commercial vessel upgraded from using bolts to high-performance marine anchors and recorded a 30% improvement in overall stability under adverse weather conditions. The new system also demonstrated a significant reduction in maintenance downtime.

- Construction Projects: In a large-scale residential project, engineers replaced standard toggle bolts with high-quality anchors in drywall applications. The improved load distribution resulted in a 25% decrease in repair incidents within the first two years.

- DIY Installations: Homeowners who opted for advanced anchors for heavy wall-mounted fixtures reported higher satisfaction and fewer instances of fastener failure compared to installations using standard bolts or toggle bolts.

Data published on ResearchGate confirms that the integration of modern anchors into fastening systems results in better load management and longer lifespan. These findings are critical for industries where safety is paramount.

Practical Tips for Achieving Maximum Performance with Anchors

To ensure that your project benefits from the superior performance of anchors, consider the following practical tips:

- Pre-Installation Inspection: Always check the substrate for any signs of damage or degradation before installing anchors. A healthy substrate is vital for achieving the best possible grip.

- Correct Sizing: Use anchors that are appropriately sized for the load and the type of material you are working with. Manufacturers typically provide load ratings and substrate recommendations.

- Drilling Best Practices: When installing anchors, ensure that you drill the correct pilot hole. This is particularly important in hollow materials where an oversized hole can significantly reduce holding power.

- Adherence to Instructions: Follow the manufacturer’s installation guidelines meticulously. Even minor deviations from recommended procedures can impact the performance of anchors.

- Periodic Testing: After installation, it is advisable to periodically test the hold of anchors to ensure they remain secure. This proactive approach helps identify any early signs of failure before a critical load is applied.

Implementing these strategies not only improves the immediate performance of your fastening system but also contributes to long-term durability and overall safety.

Summarizing When to Use Anchors Over Other Fasteners

Choosing between anchors, bolts, and toggle bolts ultimately hinges on several key factors:

- Substrate Type: For solid substrates like wood, bolts may suffice; however, for hollow or compromised materials such as drywall, anchors offer a more reliable solution.

- Load Requirements: In applications where high loads and dynamic forces are present, the superior load distribution of anchors is crucial.

- Environmental Conditions: Outdoor, marine, or high-humidity environments benefit from using anchors made with corrosion-resistant materials.

- Ease of Installation and Maintenance: Anchors are designed for straightforward installation and require less frequent maintenance than some other fasteners, making them ideal for both commercial and residential projects.

By evaluating these factors, you can confidently decide when to use anchors over bolts or toggle bolts, ensuring that your fastening solution is both effective and long-lasting.

Final Thoughts on Fastener Selection

Making an informed fastener selection is paramount to the success of any project. The benefits of using modern anchors—including superior holding power, ease of installation, and long-term durability—make them a smart choice for projects that require reliable load distribution. While bolts and toggle bolts have their place, the specialized designs and engineered performance of anchors often make them the preferred option for demanding applications. With comprehensive research, expert recommendations, and positive real-world data, investing in high-quality anchors can lead to safer, more efficient, and more sustainable project outcomes.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”