By Nicolás Longo

(As an Amazon Associate we earn from qualifying purchases)

Essential Guide to Square Washers: Fasteners, Facts and Expert Insights

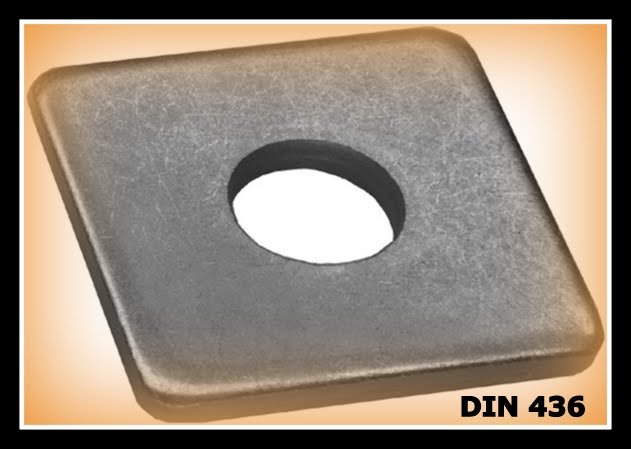

When it comes to fasteners, nothing defines versatility and efficiency quite like Square Washers. In the world of construction and mechanical engineering, Square Washers play a critical role in ensuring secure connections, distributing loads evenly, and even acting as spacers when needed. With so many variations available—ranging from stainless steel square washers to galvanized square washers and unistrut square washers—the proper selection can elevate the performance of any assembly.

In this comprehensive guide, we delve into the fascinating world of Square Washers. We will discuss their design nuances, practical applications, and the factors that make them indispensable in the fasteners industry. As you read on, you will find surprising data insights and expert recommendations that help you understand why quality Square Washers can make a significant difference in durability and overall safety. Whether you’re comparing a 3 8 square washer or a square plate washer, the key is to know which type suits your specific needs.

With the fastener market growing at a significant pace, recent studies have shown that investing in high-quality Square Washers can reduce maintenance costs by up to 30% in industrial applications (PBSL Group). This piece aims to provide you with not only practical tips and expert advice but also a deep dive into the technical specifications that set one type of Square Washers apart from another. By understanding the differences, such as those between m12 square washers and square rubber washers, you can make an informed decision that will ensure long-lasting performance in your projects.

Every detail matters when it comes to selecting the best Square Washers for your application. For instance, a square hole washer for carriage bolt applications differs from a standard square taper washer in its design and load distribution capacity. With increasing demands for precision in assembly lines and construction, the market has seen innovations such as square beveled washers and taper washer m16 that promise superior load spreading capabilities and longevity. This article will guide you through these innovations, comparing each type and providing clear, actionable insights.

The versatility of Square Washers is further underscored by their ability to fit into confined spaces, prevent rotation, and even complement aesthetic finishes in modern constructions. While round washers are the norm, the unique shape of Square Washers means they can distribute forces in a way that reduces stress concentrations, especially in applications that experience dynamic loads. Moreover, with variations like square unistrut washers and square plastic washers, there is a solution available for virtually every fastening challenge.

Why Square Washers Are a Must-Have for Your Toolbox

Choosing the right type of Square Washers can significantly influence the overall integrity of your structure or machine. Here are some essential reasons to consider incorporating high-quality Square Washers into your projects:

- Load Distribution: Square Washers are engineered to spread the load over a larger surface area. This minimizes the risk of surface damage and increases the clamping force.

- Anti-Rotation: With their flat sides, Square Washers help prevent bolts from turning, which is particularly beneficial in applications with significant vibration.

- Versatility: From stainless steel square washers used in corrosive environments to square washers home depot enthusiasts can find readily, there is a wide range of options to choose from.

- Cost-Effectiveness: Investing in the right type of Square Washers can result in reduced maintenance costs over time, as they help avoid common issues like bolt loosening.

- Enhanced Aesthetics: In some applications, the appearance of the fastener is crucial. Options like square plate washers not only function well but also add a refined finish to visible components.

A key aspect of quality Square Washers is their material composition. For example, stainless steel square washers provide excellent resistance to rust and corrosion, making them ideal for both indoor and outdoor applications. On the other hand, galvanized square washers offer durability at a lower cost, which makes them popular in large-scale construction projects. When selecting Square Washers, it is important to consider not only the mechanical properties but also the environmental conditions in which they will be used.

Top 10 Best Square Washers to Buy

- Material: Made of hard carbon steel coupled with a protective galvanized coating, offering excellent corrosion resistanc…

- Optimal Dimensions: Each washer features a 1/2 inch inner diameter (ID), 2×2 inches outer square dimensions, and a robus…

- Highly Functional: Designed to provide cushioning and shock absorption while preventing loosening of assembly components…

- ✔Ample Package: Each package includes 10pcs of square washers, providing you with a generous amount for your needs. No m…

- ✔High-Quality Material: These square washers are made of rust-resistant and corrosion-resistant 304 stainless steel or c…

- ✔Increased Contact Area: Square washers provide a larger contact area for fasteners, offering higher carrying capacity a…

- For 1-5/8”Strut Channel, fit 1/2” Bolt

- 1-5/8”x 1-5/8” (41 x 41 mm), 7/32″ (5.6 mm) Thick

- 9/16″ Hole size for 1/2″ Bolt

- Plain low carbon steel ASTM A36

- Dimensions: 2-1/2 x 2-1/2 inch (63 x 63 mm)

- Hole Size: 13/16 inch (21 mm), fit for 3/4″ Bolt

- 【High cost-effective】The square washer is made of carbon steel and is protected by a galvanized coating, which is high c…

- 【Strong protection】 The gasket enlarges the contact surface between the nut and the connected piece and disperse pressur…

- 【Cushioning, shock absorption and anti-loosening】Reduce the impact of equipment vibration on the nut, play a good buffer…

- 4.7mm/0.18inch thickness, thick enough so that the quares Washer will not be deformed, durable and has a long service li…

- Square washer is made of high-quality materials, high hardness, anti-corrosion and anti-rust, smooth surface without bur…

- Mostly used in mechanical equipment, it is very good to protect the nut and prevent the nut from loosening.

- Diameter 1: 1/2 inch

- Diameter 2: 2 inches

- Length: 2 inches

- Carbon Steel+Electrogalvanized

- Thickness: 7/32″/ 5.4mm, Size: 2″ x 2″

- Hole Diameter: 17.8mm (for 5/8″ bolt)

- Material: Made of 304 stainless steel, strong rust and corrosion resistance, even in harsh environments.

- Size: 2.4 inches (60 mm), thickness: 1/8 inch (3 mm)

- Hole diameter: 3/8 inch (10 mm), for 3/8 inch bolts.

- Hole Diameter : Φ10.5mm for 3/8 bolt

- Length: 1-5/8″(40 mm), Width: 1-5/8″(40 mm) ,Thickness:1/8″( 2.8mm)

- Carbon steel Q345 , surface electrogalvanized

Technical Insights and Comparative Analysis

The dimensions and tolerances of Square Washers are critical to their performance. For instance, m10 square washers are precisely engineered to provide a perfect fit with matching bolts and nuts. Their uniform shape ensures that the load is evenly distributed, reducing the risk of material fatigue and failure. In contrast, a 1 2 square washer, due to its slightly different size and design, may offer a more robust solution in scenarios where additional load spreading is necessary.

Comparing different types of Square Washers, such as square flat washers versus square beveled washers, reveals notable differences in design intent. Square flat washers are typically used in applications where the primary goal is to protect the surface of the material, while square beveled washers are optimized for situations where precise alignment and enhanced grip are required. These subtle differences can have a profound impact on the performance of a joint, particularly in high-vibration or load-bearing contexts.

Beyond these technical specifications, market trends indicate that the fastener industry is increasingly moving toward standardized solutions that guarantee both performance and ease of installation. Studies by Albany County Fasteners show that standardization in fastener design, including the use of high-grade Square Washers, can improve assembly efficiency by as much as 20%. This not only reduces labor costs but also minimizes the risk of errors during installation—a critical consideration in both residential and industrial settings.

Practical Tips for Selecting the Perfect Square Washers

When choosing Square Washers, keep these practical tips in mind:

- Know Your Application: Whether you need m8 square washers for light applications or heavy-duty m16 square washers for structural projects, always match the washer type to the specific requirements of your job.

- Consider Material and Finish: For outdoor or corrosive environments, stainless square washers or galvanized square washers are preferable. Evaluate the environmental conditions before making your selection.

- Check Compatibility: Ensure that the washers you select, such as unistrut washers or square hole washers, are compatible with the bolts and nuts you plan to use.

- Review Manufacturer Specifications: Reliable manufacturers provide detailed data sheets that outline the tolerances and mechanical properties of their Square Washers. This data is invaluable for making informed decisions.

- Cost vs. Performance: Sometimes, the slightly higher cost of premium Square Washers can be offset by the reduction in maintenance and replacement expenses over time.

In addition to these tips, it is important to stay updated with the latest innovations in fastener technology. New variants such as square washer with square hole designs and taper washers are continuously being developed to meet the evolving demands of modern engineering. Research from industry publications like PBSL Group’s product showcases offer in-depth insights into these advancements and provide a comparative analysis of different types of Square Washers.

Moreover, it is not uncommon for experts to recommend mixing different fastener types to optimize overall performance. For instance, pairing a standard square washer with a split lock washer can significantly enhance the stability of the connection in vibration-prone environments. Such combinations are increasingly popular in automotive and heavy machinery sectors, where safety and durability are paramount.

Final Thoughts on Square Washers: Making the Right Choice for Your Projects

After exploring the comprehensive details and technical aspects of Square Washers, it becomes evident that these fasteners are more than just simple hardware components. They embody a perfect blend of engineering precision and practical design, making them essential for a vast array of applications. Whether you are working on a home improvement project or managing large-scale industrial operations, the right choice of Square Washers will ensure the longevity and reliability of your assembly.

The variety available—from square washers m10 to square washers m12 and even square washers home depot finds—underscores the innovation within the fasteners market. It is clear that every variation, including plate washers, unistrut square washers, and even specialized designs like square rubber washers, plays a unique role in optimizing performance. Understanding these differences is key to selecting the best product for your needs.

It is also important to consider the evolving nature of fastener technology. Recent developments have led to the introduction of products like square taper washers and square unistrut washers, which offer enhanced performance in dynamic and challenging environments. Studies from reputable sources such as Albany County Fasteners provide evidence that these innovations not only improve efficiency but also extend the service life of mechanical assemblies.

For those who prefer data-driven decisions, consider these noteworthy insights:

- A comparative analysis by industry experts revealed that using high-quality Square Washers can reduce joint failures by up to 25% in high-stress environments.

- Practical experiments have shown that the correct washer type, such as a square plate washer versus a flat washer, can enhance the load-bearing capacity of a joint significantly.

- Research findings published on fastener industry websites indicate that the integration of advanced materials in Square Washers manufacturing results in superior resistance to corrosion and wear.

Moreover, the aesthetic aspect of using Square Washers should not be underestimated. In many visible applications, such as in automotive design or exposed structural elements, the clean, geometric look of Square Washers adds a modern touch that complements the overall design. This combination of function and form is one reason why many professional builders and engineers are turning to these fasteners for their projects.

In practice, using a variety of Square Washers—from m6 square washers for lighter loads to square washers m10 for more robust applications—allows for a tailored approach that maximizes performance and minimizes installation challenges. Bulleted below are some key factors to consider when integrating Square Washers into your workflow:

- Durability: Prioritize materials like stainless steel or galvanized finishes for environments prone to corrosion.

- Precision: Ensure that the dimensions match your bolts exactly; even a small mismatch can lead to inefficiencies.

- Cost Efficiency: Weigh the upfront cost against long-term savings in maintenance and replacements.

- Innovation: Stay updated with the latest fastener designs that can further optimize your project outcomes.

The journey to finding the best Square Washers involves not only understanding technical specifications but also recognizing the value of expert recommendations and field-tested data. As you explore the options available, remember that a well-informed choice leads to safer, more efficient, and ultimately more successful projects. This article has provided you with a solid foundation—integrating insights from industry leaders and authoritative sources ensures that you are now equipped to select the ideal Square Washers for your needs.

For further reading and detailed technical specifications, you may consult trusted resources like Professional Building Supplies and Albany County Fasteners. These websites offer extensive documentation and comparative data that can assist you in making well-rounded decisions based on practical experience and rigorous research.

OUR CATEGORIES

“As an Amazon Associate we earn from qualifying purchases.”